For those that have automated their home brewery setups, how did you automate the control of the flow rate? For example during sparging, you probably don't want to have the ball valve at the output of the MLT open full throttle as it may compact the grain bed.

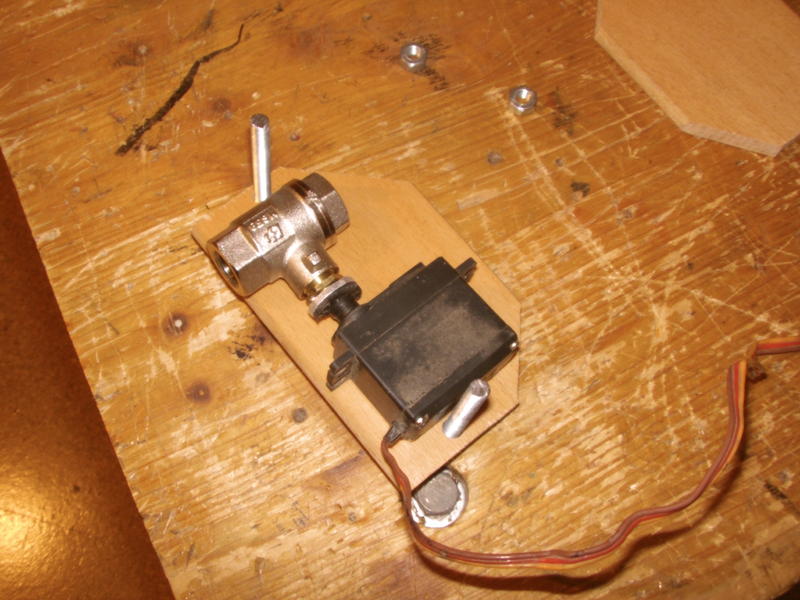

From what I've read, motorized ball valves are either completely open or complete closed so that won't do it. Some have suggested using a PWM to control the input voltage to a 12V DC pump to control GPM but others have advised against it. Btw, I'm not set on using a DC motor; just using that as an example.

So what's the scoop? Anyone able to successfully automate flow control?

Thanks for the help!

From what I've read, motorized ball valves are either completely open or complete closed so that won't do it. Some have suggested using a PWM to control the input voltage to a 12V DC pump to control GPM but others have advised against it. Btw, I'm not set on using a DC motor; just using that as an example.

So what's the scoop? Anyone able to successfully automate flow control?

Thanks for the help!