I've been planning the transition to all-grain for quite some time and I finally was able to put together everything. My goal was to keep this mash tun as simple and cheap as possible while being big enough to handle 10 gallon batches. The cooler I decided on was the 60 quart Igloo Ice Cube cooler with 'ultratherm insulation'. This cooler is plenty big enough to handle large 10 gallon batches and easy on the budget at $25. Hopefully the 'ultratherm' insulation will keep the temps in range for the full mash time. Here is a picture of the cooler:

I discovered from a few other posts that the stock bulkhead could be removed and the hole was the perfect size for a 1/2 MPT coupling. This keeps me from having to drill a hole in the cooler, and I kept the stock bulkhead around in case I decide to use this for a cooler in the future. Another plus about this cooler is that there is no insulation where the bulkhead is. This allowed me to keep my bulkhead fittings very simple (and cheap). Hopefully, this lack of insualation in this area won't result in heat loss.

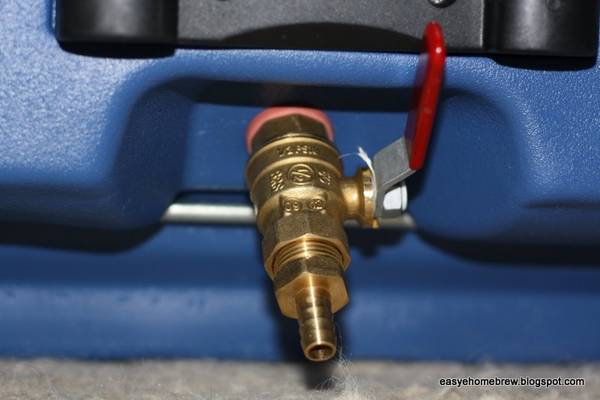

For the bulkhead fitting, I reused the stock igloo bulkheads soft rubber gasket, and plastic gasket ring. If this worked for the stock bulkhead, I figured it would work for my purposes. Since I am going to use a CPVC manifold. I used a 1/2 CPVC MPT adapter as the male portion of the bulkhead. I also used rubber hose gasket on the outside portion of the bulkhead, and screwed the valve on the end. I tested this out, and it doesn't leak! I am happy with this set up because it was super cheap:

Valve $6

Hose Gasket $1.50 / 10 pack

CPVC 1/2 MPT $.50

3/8 Hose Barb $2.50

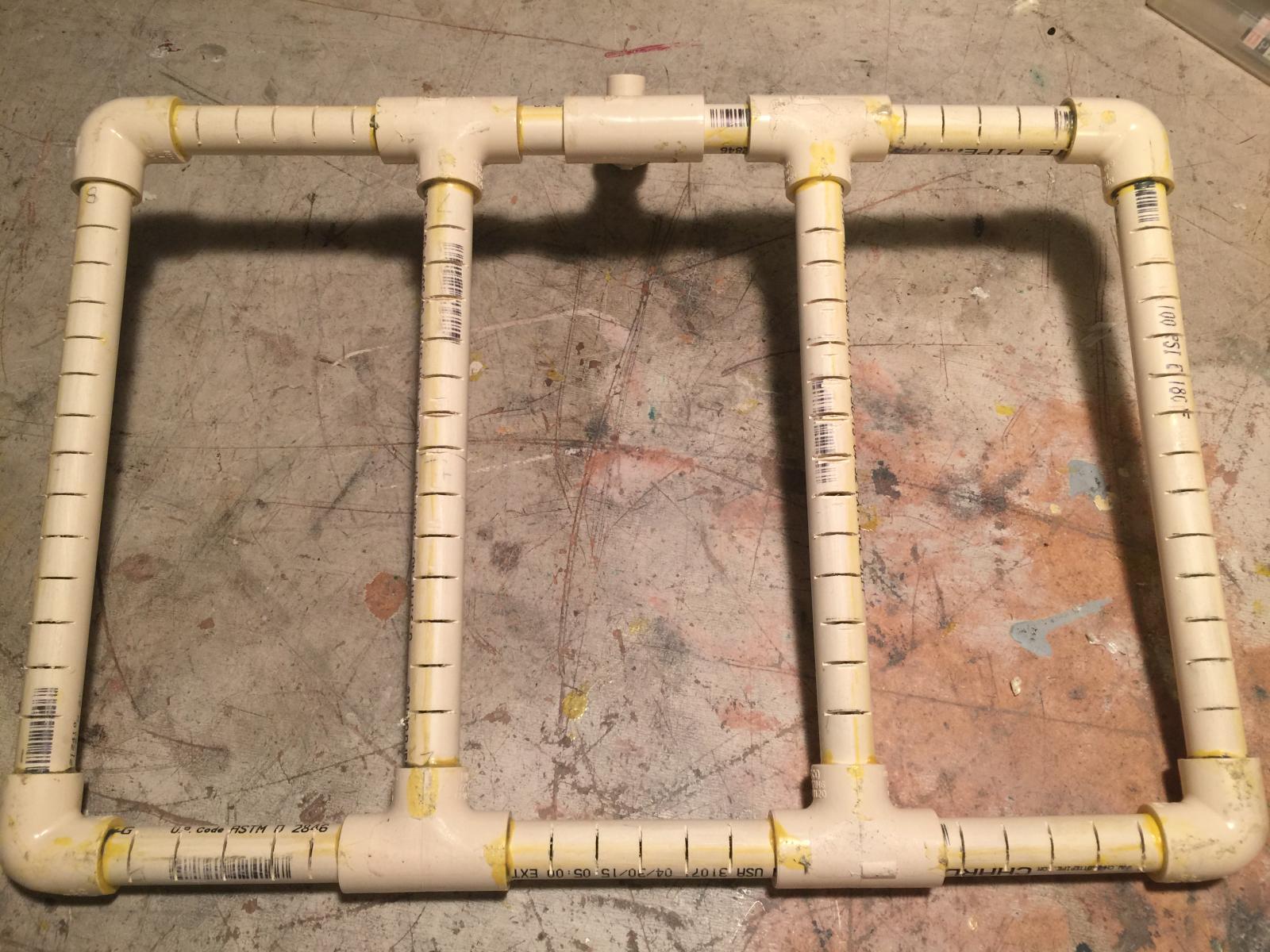

On this inside I fitted a pretty basic CPVC manifold. I had to put a 90* fitting in because the bulkhead comes in at a funky 45* angle. I tested this out as is and it drains all the water out except for an inch or so at the bottom.

The bottom line for everything was $40. I can't complain with the price tag, lets just hope this thing will make some beer! My next job is to the drink the beer on tap so that I can make room in my fermentation chamber for my first all-grain batch. Let me know if anyone has any recommendations or comments.

-Erik