So, my Fridgidaire model FRC455GB took a dump sometime last night. Went to pour a pint this fine afternoon and the temp was 61F in the fridge.

Knowing something about refrigeration systems I started poking around. Traced the problem back to the PTC Thermister motor start. A device that controls voltage to the start winding. I've been looking on the internet all afternoon and found 1 supplier. In China, Minimum order - 10,000 units. All I need is 9,999 other people who need the same device.

My search continues. I'll probably convert to a more traditional "solid state" start.

My point. Whoever owns one of these fridges runs the risk of being, "dead in the water", over a 5 cent disk.

I'm posting this here because it directly relates to the mini fridge in this thread and many people have this unit.

Here's the scoop.

They do not make replacement parts for this unit. If your unit stops the most likely cause is PTC Thermister motor start. It seems to be the week link. It's found on the compressor and supplies power to the start winding. The thermistic disk is very brittle and can easily break.

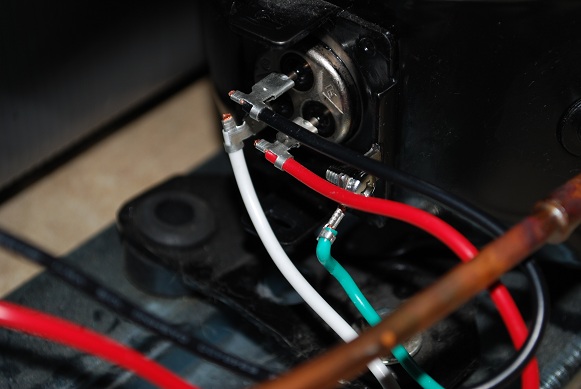

The offending part.

The following is a legitimate fix to an otherwise dishonest business practice by the manufacture. I have tried numerous suppliers to obtain the original replacement part. the "3 in'1 start" fix is not a golden bullet, but will will give many years of extended life to an otherwise 1 year old piece of garbage.

Your compressor is fine if it OHM's out. (Continuity between the start and common terminal, and the run and common terminal, and there is no short to ground.

The fix is simple and cost about $10 + 1 hour of your time. It's a 3 in' 1 start. Model #RC0810. It supplies power to the run and start winding and has its own overload.

Due to limit of pics you will see the 3 in' 1 start later.

To replace.

Unplug unit from wall outlet.

Remove cover from side of compressor. Spring clip holds it on. pry off with screwdriver.

After cover removed you can see the PTC Thermister and overload.

Remove everything under cover. Pull it straight off pins .Non of it will be reused. What's left is 3 pins for the run/start winding. Common on top, start on left, run on right.

Now, to install the 3 in' 1 start. there are 5 wires. Red, Black, and White on one side and 2 Black on the other.

Start with the R,B,W. Black goes on the top pin, White goes on the left pin, and the Red goes on the right pin.

The 2 Black wires. 1 is the 120V from the thermostat suppling voltage to the compressor. The other is your 120V neutral.

Put the cover back on the compressor and the unit is ready to run again.

Quick, simple fix.

If unsure with electricity, consult an experienced neighbor.