6/18/2016 update

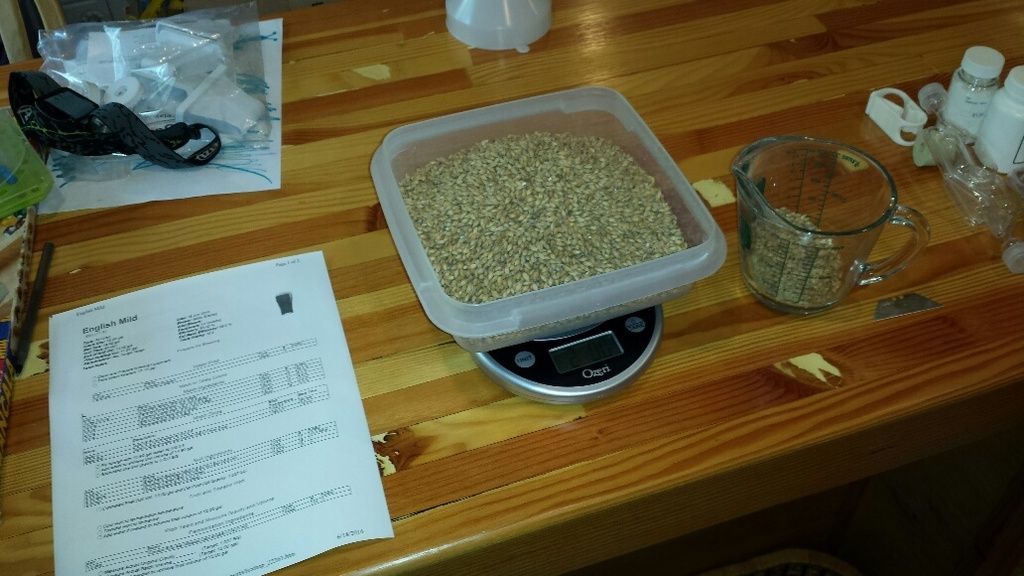

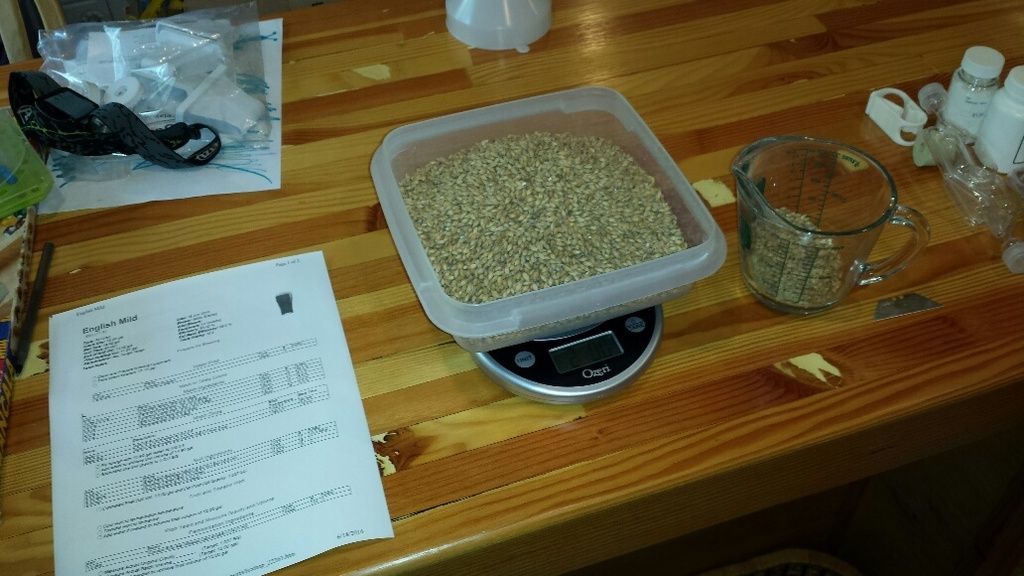

first brew day is here! got going at 7 am and started heating the strike water. i was a little tired from staying up late to let the ro/di system finish but i was too excited to worry about it. while the water was heating, i started weighing out the grain. i am brewing an english mild, marris otter is the base. a big bag of grain:

weighing the grain. beersmith recipe printed out for reference:

all the grains weighed out:

leftover specialty malts are individually bagged and labeled. the labels on the bags from my lhbs peel off easily so i stuck them right on the ziplock bags. i crossed out the '1 lb' designation and wrote down the weight of the leftover grain. i also added today's date:

time to mill. i milled outside to cut down on dust in the house:

lot of milling problems. i used a feeler gauge to set the rollers to 0.045". i ran the first set of grain through and took a look at the crush. it looked like half the grains hadn't been crushed. i looked ta the rollers and sure enough, they were crooked with a gap larger than the grain. so a large amount of grain simply flowed through the rollers. i tightened everything back up but noticed one roller was still loose and could not be tightened. needless to say, very frustrated. it was then that i noticed the eye bolts for locking the rollers in place had additional nuts that were tight against the frame of the crusher. i loosened those and found i could tighten down the eye bolts much further. i set my gap and got everything locked in place. tried to run some more grain but the driven roller spun with no resistance and no grain flowed through. after a bunch of time screwing around, found out that the non-driven roller was stuck. learned at that moment that both rollers need to spin for the system to work. milled the rest of the grain and moved on. crush looked okay but seems finer than it should be:

by now, my hlt was up to temp (and had been for about 20 minutes). i transferred some strike water to the mlt and realized i didn't add any of my brewing salts. rather than treat a portion of the water. i decided to pump the mlt water back into the hlt. so i switched some hoses around and got that going. what i didn't account for was that when i turned off the recirc in the hlt, the stagnant water around the rtd cooled and 'fooled' the pid into thinking the hlt was cooler than it really was. after fooling around with the hoses, moving the water and turning everything back on, the hlt was now at about 170 degrees. so i needed to wait for that to cool. in the meantime, i took the remaining marris otter and got it into buckets. each bucket gets a label with grain type, approx amount and date. i used the date on teh sack rather than today's date:

mash in action and recirc through the herms coil in the hlt:

science lab! this is opposite of my brew stand. i don't have any other working space in the are so the top of the fermentation chamber serves as a workbench. checking ph of the mash. with ro water and the dark grains in the grain bill, no need to add any lactic acid for ph correction:

while the mash is happening, i moved on to weighing out the hops. hop bill for this english mild is stupid-easy, 2 oz of kent goldings:

vacuum-sealed the rest of the hops in 2 oz packages and moved them into the deep-freeze chest freezer. packages labeled with hop type aa%, weight and date:

mashing out:

first runnings into the bk. this recipe has a light grain bill and i ended up rushing the sprage, only about a half hour or so:

finishing up the sparge:

starters pulled out of the fridge, excess liquid decanted and warming up on the bar:

hot break. not much foaming with such a small grain bill:

and a nice boil:

progress shot of mlt cleanout during the boil:

boil complete, all setup for chilling and transfer to carboys:

chilling was a bear. my tap water is about 64 degrees and i had it wide open. using a conterflow chiller as single pass, i really had to crank down wort flow to get 65-70 into the carboy. cfc is stainless which i knew would be slower than copper but everything i have read implies 10-15% slower. took damn near an hour to chill ten gallons. progress shot:

boil kettle shot, heating element and hopstopper starting to show:

kettle drain complete. hop amount was small but i was impressed with the hopstopper:

oxygenating the wort:

yeast pitched:

and a couple happy campers sitting in the fermentation chamber:

boil kettle mess:

things that went well:

things that went bad:

i was very greedy and assumed 95% efficiency, came in way low on og. plus i made a recipe error and ended up with an extra gallon or so of water going into the fermenters. this will be a weak beer and will likely taste thin. gravity readings were weitrd as well, post-boil was only a couple points less than pre-boil. not sure if that was user or equipment error. i used a refractor for gravity readings, future brews will use a hydrometer to compare readings. grain mill problem is solved. chiller is an issue that requires investigation. next batch will use a lower efficiency for the recipe.

whole day took about nine hours, from heating strike water to lights off. i should be able to speed that up on the next one, especially with that mill and water salt issue resolved.

first brew day is here! got going at 7 am and started heating the strike water. i was a little tired from staying up late to let the ro/di system finish but i was too excited to worry about it. while the water was heating, i started weighing out the grain. i am brewing an english mild, marris otter is the base. a big bag of grain:

weighing the grain. beersmith recipe printed out for reference:

all the grains weighed out:

leftover specialty malts are individually bagged and labeled. the labels on the bags from my lhbs peel off easily so i stuck them right on the ziplock bags. i crossed out the '1 lb' designation and wrote down the weight of the leftover grain. i also added today's date:

time to mill. i milled outside to cut down on dust in the house:

lot of milling problems. i used a feeler gauge to set the rollers to 0.045". i ran the first set of grain through and took a look at the crush. it looked like half the grains hadn't been crushed. i looked ta the rollers and sure enough, they were crooked with a gap larger than the grain. so a large amount of grain simply flowed through the rollers. i tightened everything back up but noticed one roller was still loose and could not be tightened. needless to say, very frustrated. it was then that i noticed the eye bolts for locking the rollers in place had additional nuts that were tight against the frame of the crusher. i loosened those and found i could tighten down the eye bolts much further. i set my gap and got everything locked in place. tried to run some more grain but the driven roller spun with no resistance and no grain flowed through. after a bunch of time screwing around, found out that the non-driven roller was stuck. learned at that moment that both rollers need to spin for the system to work. milled the rest of the grain and moved on. crush looked okay but seems finer than it should be:

by now, my hlt was up to temp (and had been for about 20 minutes). i transferred some strike water to the mlt and realized i didn't add any of my brewing salts. rather than treat a portion of the water. i decided to pump the mlt water back into the hlt. so i switched some hoses around and got that going. what i didn't account for was that when i turned off the recirc in the hlt, the stagnant water around the rtd cooled and 'fooled' the pid into thinking the hlt was cooler than it really was. after fooling around with the hoses, moving the water and turning everything back on, the hlt was now at about 170 degrees. so i needed to wait for that to cool. in the meantime, i took the remaining marris otter and got it into buckets. each bucket gets a label with grain type, approx amount and date. i used the date on teh sack rather than today's date:

mash in action and recirc through the herms coil in the hlt:

science lab! this is opposite of my brew stand. i don't have any other working space in the are so the top of the fermentation chamber serves as a workbench. checking ph of the mash. with ro water and the dark grains in the grain bill, no need to add any lactic acid for ph correction:

while the mash is happening, i moved on to weighing out the hops. hop bill for this english mild is stupid-easy, 2 oz of kent goldings:

vacuum-sealed the rest of the hops in 2 oz packages and moved them into the deep-freeze chest freezer. packages labeled with hop type aa%, weight and date:

mashing out:

first runnings into the bk. this recipe has a light grain bill and i ended up rushing the sprage, only about a half hour or so:

finishing up the sparge:

starters pulled out of the fridge, excess liquid decanted and warming up on the bar:

hot break. not much foaming with such a small grain bill:

and a nice boil:

progress shot of mlt cleanout during the boil:

boil complete, all setup for chilling and transfer to carboys:

chilling was a bear. my tap water is about 64 degrees and i had it wide open. using a conterflow chiller as single pass, i really had to crank down wort flow to get 65-70 into the carboy. cfc is stainless which i knew would be slower than copper but everything i have read implies 10-15% slower. took damn near an hour to chill ten gallons. progress shot:

boil kettle shot, heating element and hopstopper starting to show:

kettle drain complete. hop amount was small but i was impressed with the hopstopper:

oxygenating the wort:

yeast pitched:

and a couple happy campers sitting in the fermentation chamber:

boil kettle mess:

things that went well:

- control panel was easy to use, did excellent job holding temperatures (cross-checked with thermapen)

- ventilation system worked awesome, no sign of water accumulation in the 'gutter' on the hood

- hopstopper work as advertised

- cleanup was easy with a sink and spray arm adjacent to the brew stand

things that went bad:

- grain mill

- chiller

- system efficiency

i was very greedy and assumed 95% efficiency, came in way low on og. plus i made a recipe error and ended up with an extra gallon or so of water going into the fermenters. this will be a weak beer and will likely taste thin. gravity readings were weitrd as well, post-boil was only a couple points less than pre-boil. not sure if that was user or equipment error. i used a refractor for gravity readings, future brews will use a hydrometer to compare readings. grain mill problem is solved. chiller is an issue that requires investigation. next batch will use a lower efficiency for the recipe.

whole day took about nine hours, from heating strike water to lights off. i should be able to speed that up on the next one, especially with that mill and water salt issue resolved.