Great, I was looking for a stainless TC part solution, but it looks like there may be a bag solution which will allow me to use a more standard TC fitting and a custom bag.

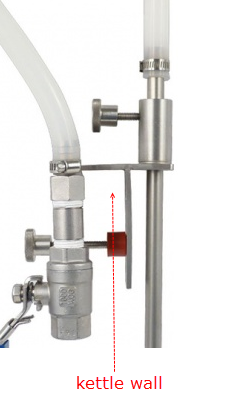

As to not hijack, wilserbrewer, can you PM me details on what you would suggest for a 10g Spike kettle with a TC port near the top? maybe a pic?

As to not hijack, wilserbrewer, can you PM me details on what you would suggest for a 10g Spike kettle with a TC port near the top? maybe a pic?

Actually I have made quite a few bags with the side seam left open several inches where it is snugged up below a side port, then wraps up and over the kettle rim and is then secured around the outside of the kettle with draw string and cord lock.