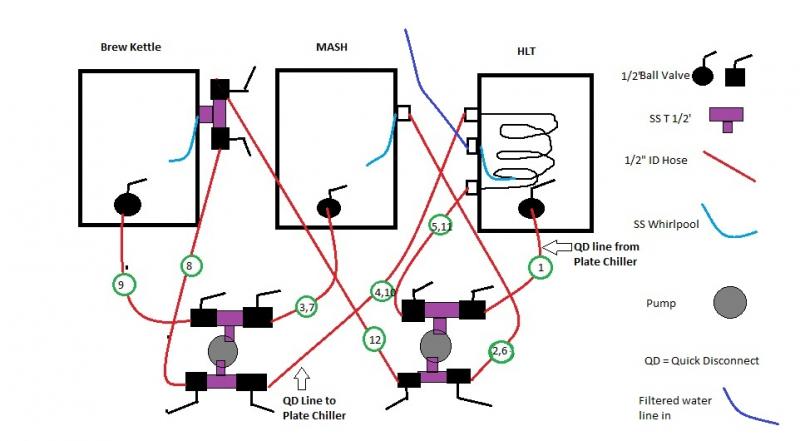

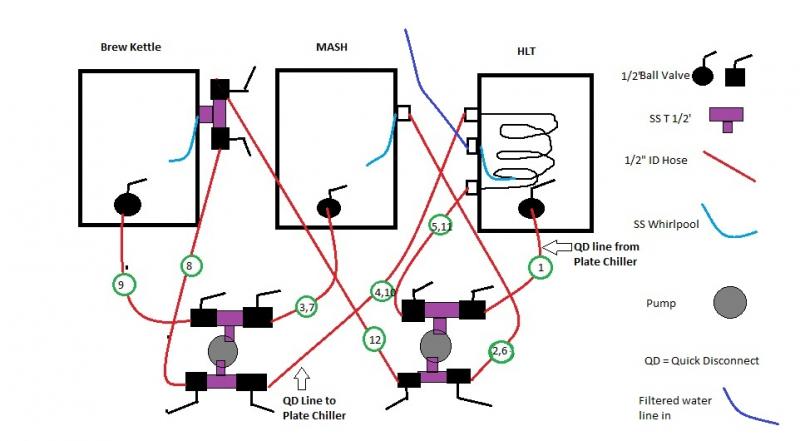

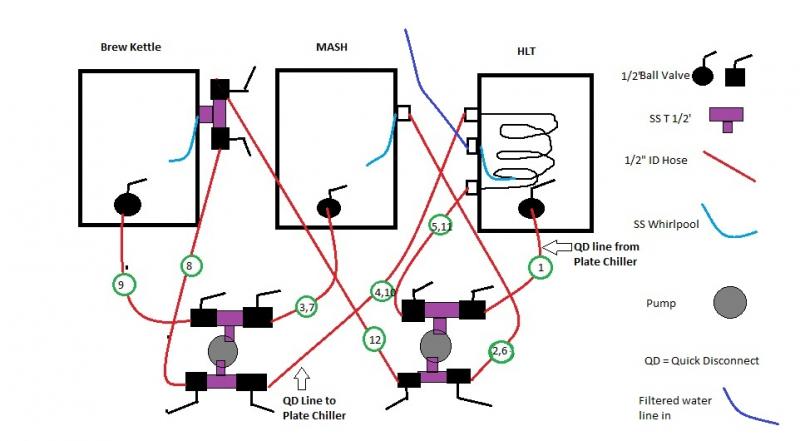

If you are going to have QD's on the hose and at the pumps why spend the extra money for the T and ball valves? In other words for the pump on the bottom left, you have a T on the out and then 2 ball valves, one going to the BK with line 8 and the other going to HLT (4,10). Why not just take off the T and a ball valve, leaving only 1 ball valve with a QD fitting, then connect the hose to it and to whichever vessel you need to pump to (BK or HLT).

It seems like you have it drawn up to have every possible connection plumbed up and you control it all manually during the brewing day. That can possibly end up being very confusing, making sure you have all the right valves open and what not. This works great for fully automated systems (using electric ball valves) but I wouldnt be able to keep track of it all myself while also worrying about everything else that goes on during brew day.