I moved to a new house with a large 3 car garage that has sufficient space for a dedicated brewery area! (The old house had what was optimistically called a two car garage but would barely hold my wife's car and two motorcycles.) My old brewing system was two Igloo coolers, a 10 gallon kettle, a propane burner and a home-made 120V RIMS cart; all of which I kept in a spare bedroom closet and dragged to-and-from the garage on brew days.

I spent a lot of time looking at the SS Brewtech and Blichmann 3V systems vs building out piecemeal. When the SS Brewtech system went on sale for ~$4500, including an oh-so-sexy 7 gallon Unitank 2.0, I pulled the trigger. The equipment is all here and looks fantastic! I have some time while waiting on the necessary electrical work and was thinking about the plumbing. The SSBT quick start guide would have me rearrange hoses throughout the brew day - just like I was accustomed to with my old rig. I'd like to simplify things and keep my lovely epoxy garage floor clean(ish).

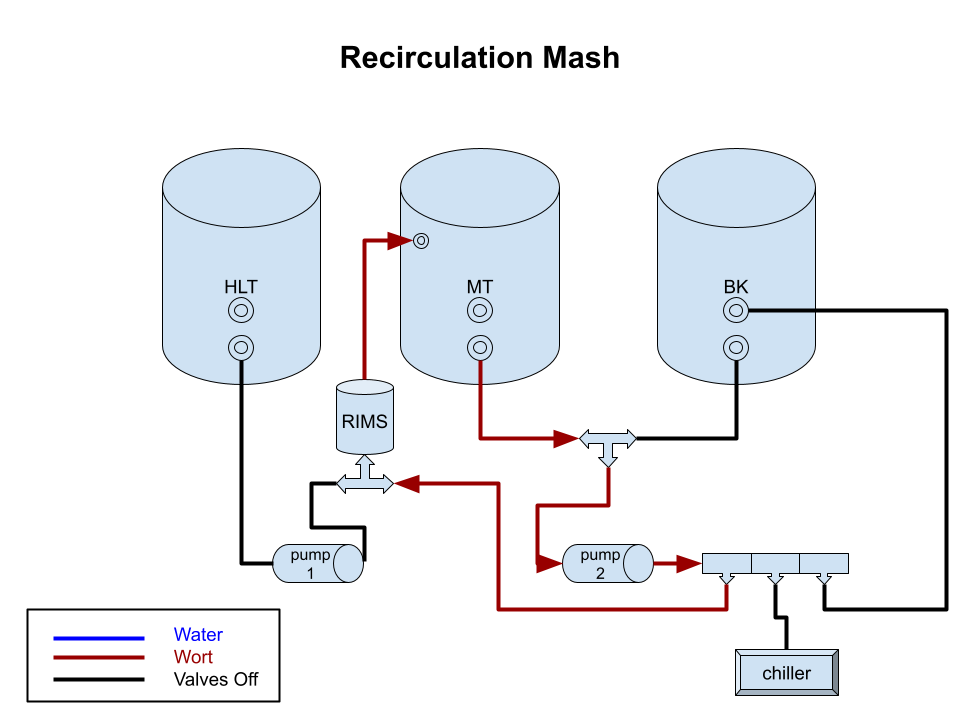

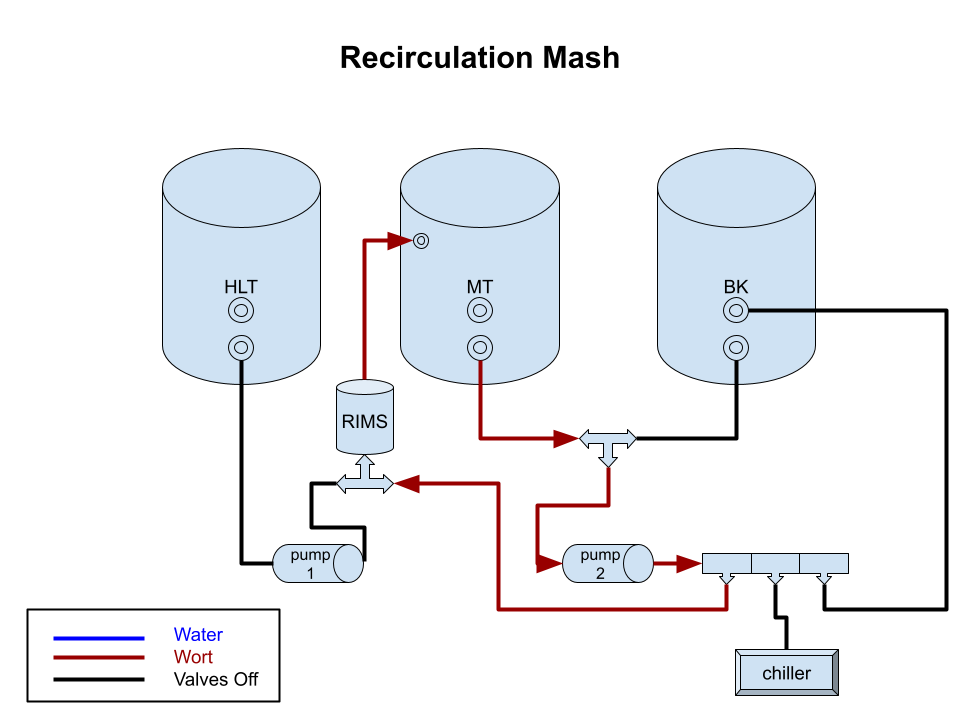

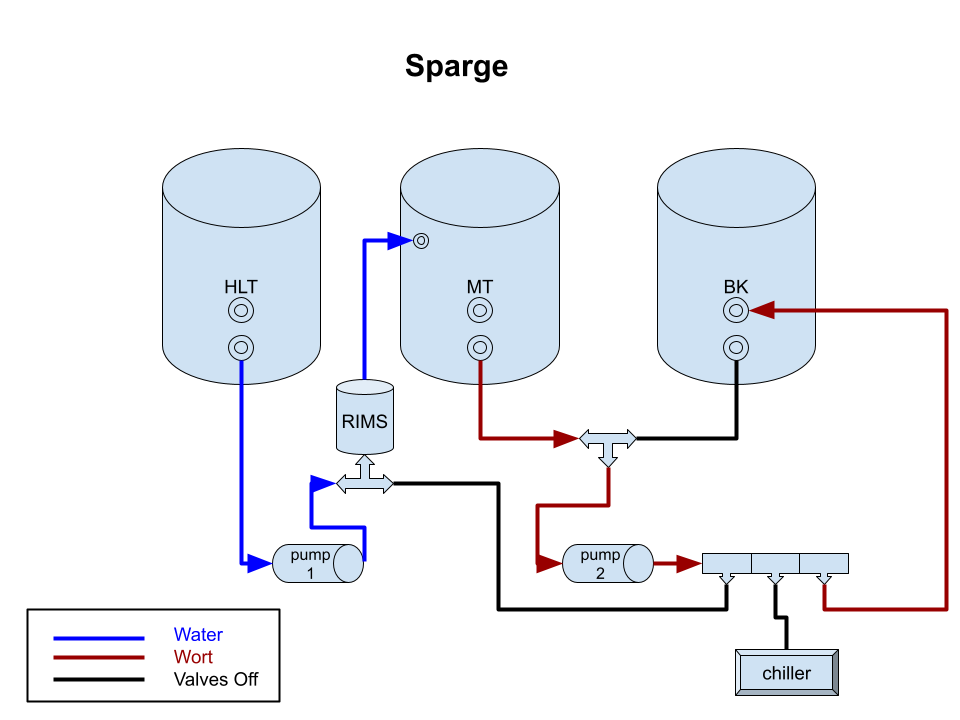

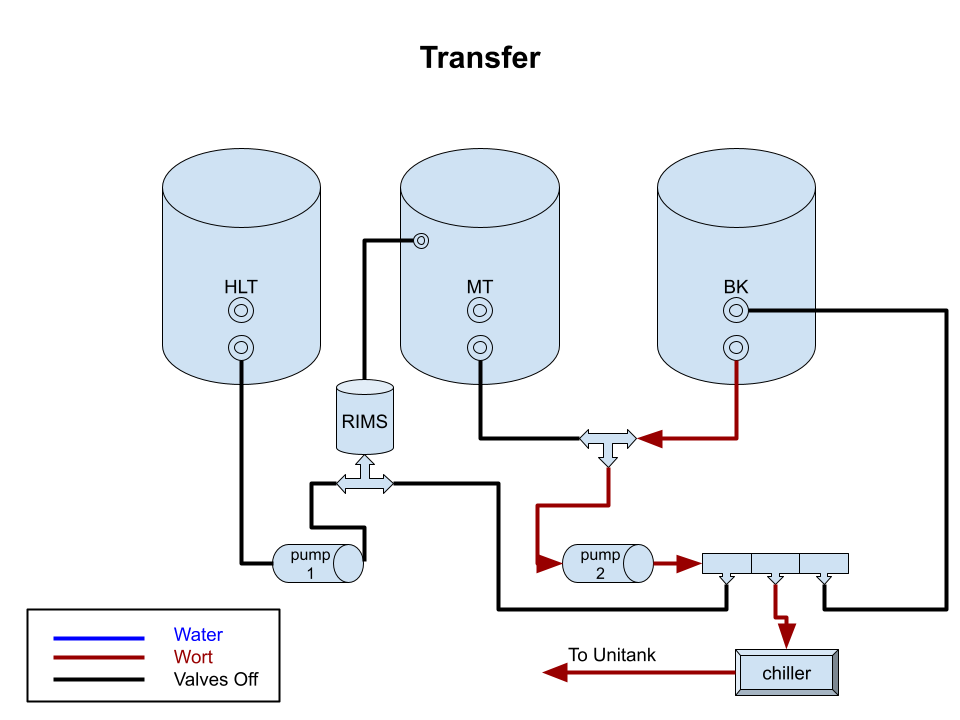

Here's my current thinking. Would appreciate any feedback.

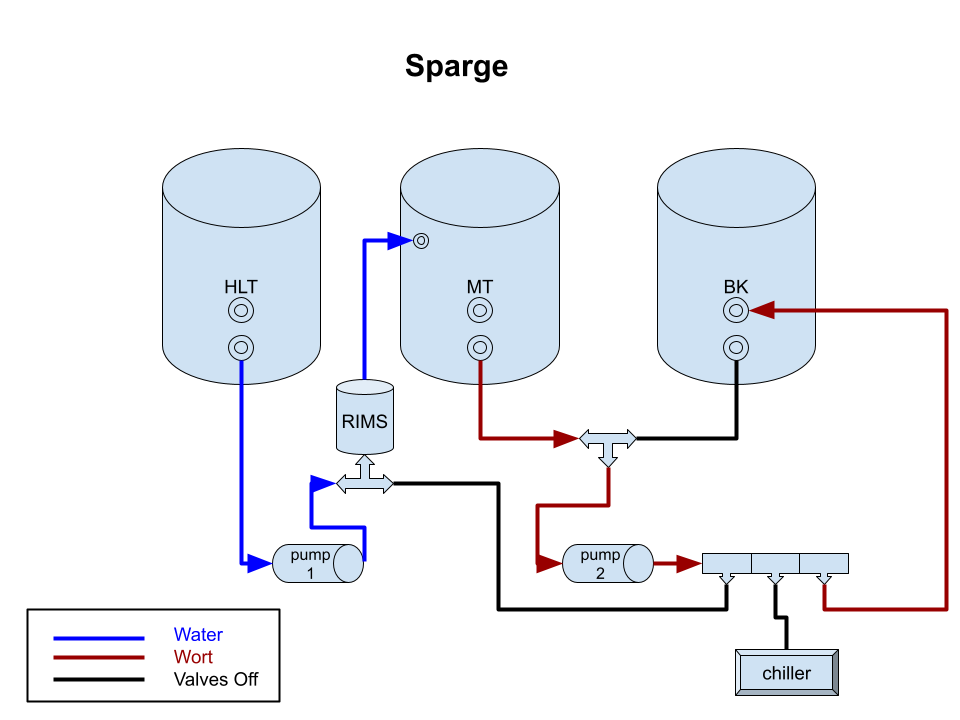

I can heat up sparge water in the HLT while during the mash.

Flow rate is determined by the output of the valve downstream from pump2. I can either continue using my Blichmann autosparge to control the flow into the HLT, or try and finesse the flow rate into the HLT to match the output.

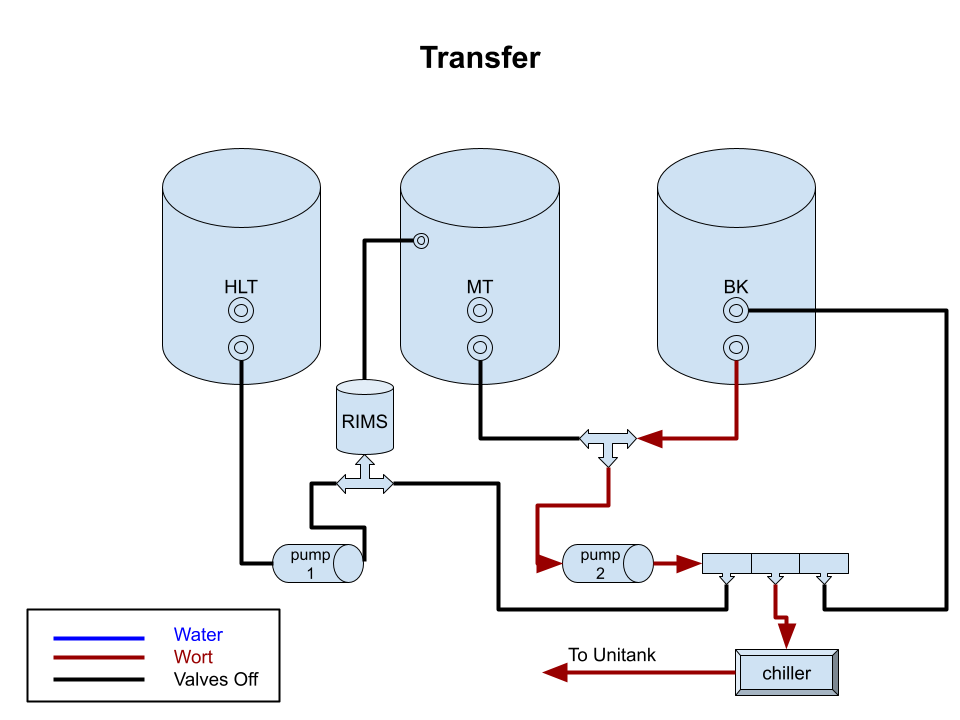

Pretty straight forward. Start the whirlpool shortly after the end of the boil. At ~200 degrees the tee distribution should get sanitized quickly.

Clean in place by running 5 gallons of hot PBW through the recirculation path, then sparge path, then whirlpool path then chiller. Repeat with rinse and sanitizer.

Suggestions? Improvements? "Hardwire" the various connections using hose barbs or go hog wild with TC connectors everywhere ($$$) or reuse a bunch of my existing camlock infrastructure at the connection points ($)?

Tom

I spent a lot of time looking at the SS Brewtech and Blichmann 3V systems vs building out piecemeal. When the SS Brewtech system went on sale for ~$4500, including an oh-so-sexy 7 gallon Unitank 2.0, I pulled the trigger. The equipment is all here and looks fantastic! I have some time while waiting on the necessary electrical work and was thinking about the plumbing. The SSBT quick start guide would have me rearrange hoses throughout the brew day - just like I was accustomed to with my old rig. I'd like to simplify things and keep my lovely epoxy garage floor clean(ish).

Here's my current thinking. Would appreciate any feedback.

- Attach a 3-way valve to the input of the RIMS to switch the source between pump1 (hot liquor) vs pump2 (wort)

- Attach a 3-way valve to the input of pump2 to switch the source between the output of the MT vs the BK

- Build an output manifold for pump2 consisting of three stainless steel tees in series, each with a valve. Then I can switch the output of pump2 to any of:

- the input to the RIMS for recirculation mashing

- the whirlpool port of the BK

- the input to my counterflow chiller for transfers

I can heat up sparge water in the HLT while during the mash.

Flow rate is determined by the output of the valve downstream from pump2. I can either continue using my Blichmann autosparge to control the flow into the HLT, or try and finesse the flow rate into the HLT to match the output.

Pretty straight forward. Start the whirlpool shortly after the end of the boil. At ~200 degrees the tee distribution should get sanitized quickly.

Clean in place by running 5 gallons of hot PBW through the recirculation path, then sparge path, then whirlpool path then chiller. Repeat with rinse and sanitizer.

Suggestions? Improvements? "Hardwire" the various connections using hose barbs or go hog wild with TC connectors everywhere ($$$) or reuse a bunch of my existing camlock infrastructure at the connection points ($)?

Tom

Last edited: