panicbuttonguy

Well-Known Member

So I want to upgrade my AG Cooler set to a Single Tier RIMS System w/automation/panel.

I have a few questions.

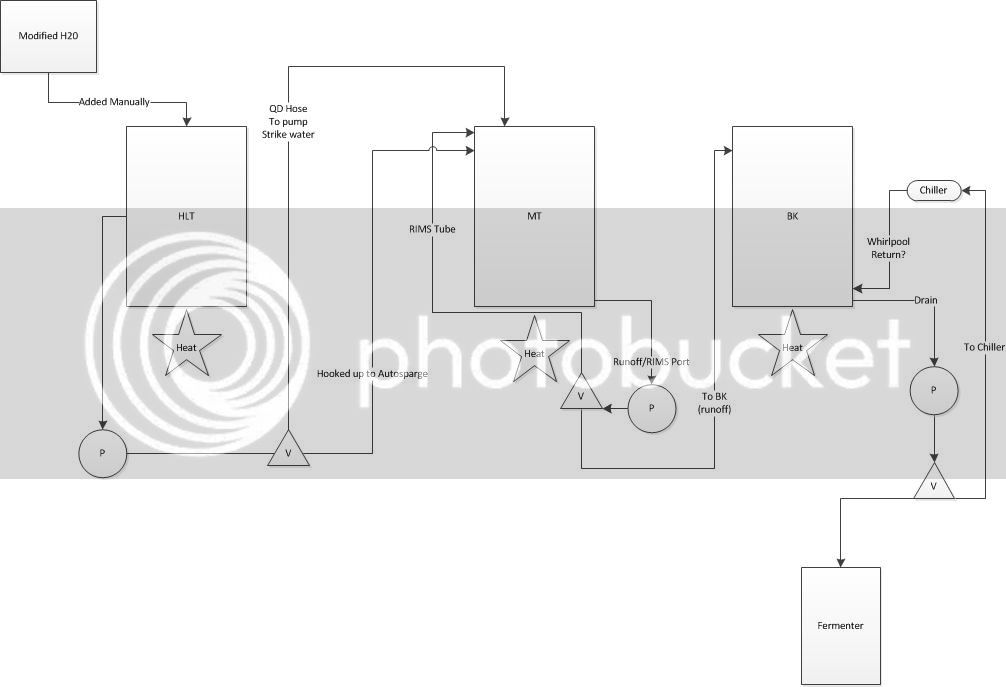

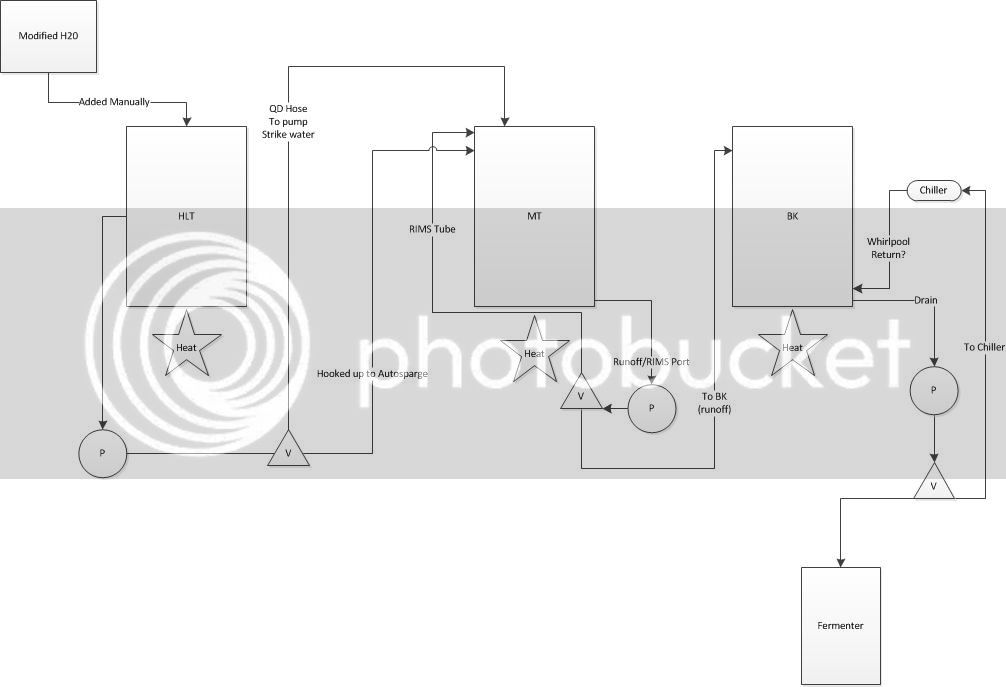

First of which, is this diagram somewhat correct for a RIMS?

If this is somewhat correct then I think I have an idea of what I'm going to need to piece together.

I want a system with high levels of automation. I know that I'm just going to buy a controller because I honestly don't think I'm capable of building one.

I'm just going to weld the stand myself from others specifications on here. Then add the burners, plumbing and valves.

Source old kegs for the kettles

I have questions on what is capable for automation.

I know that scorching the wort is a potential issue with RIMS so how do you avoid that if the burner is producing the heat to heat the mash and the tube has to run right under it? Or is that not how it works?

Obviously I have a ton of questions and am just getting started.

Please help me wrap my mind around this. Thanks.

I have a few questions.

First of which, is this diagram somewhat correct for a RIMS?

If this is somewhat correct then I think I have an idea of what I'm going to need to piece together.

I want a system with high levels of automation. I know that I'm just going to buy a controller because I honestly don't think I'm capable of building one.

I'm just going to weld the stand myself from others specifications on here. Then add the burners, plumbing and valves.

Source old kegs for the kettles

I have questions on what is capable for automation.

I know that scorching the wort is a potential issue with RIMS so how do you avoid that if the burner is producing the heat to heat the mash and the tube has to run right under it? Or is that not how it works?

Obviously I have a ton of questions and am just getting started.

Please help me wrap my mind around this. Thanks.