pedalbrewing

New Member

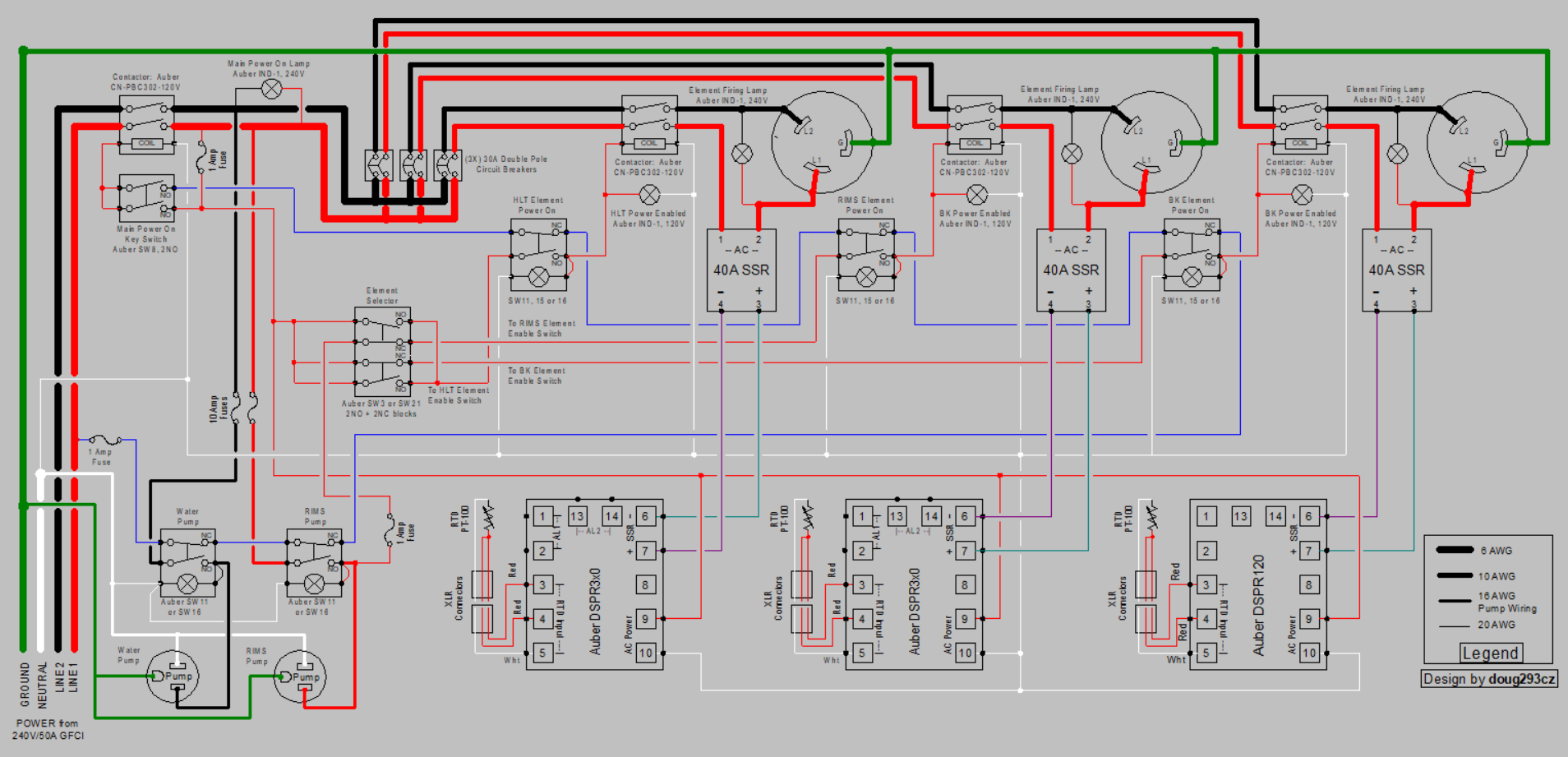

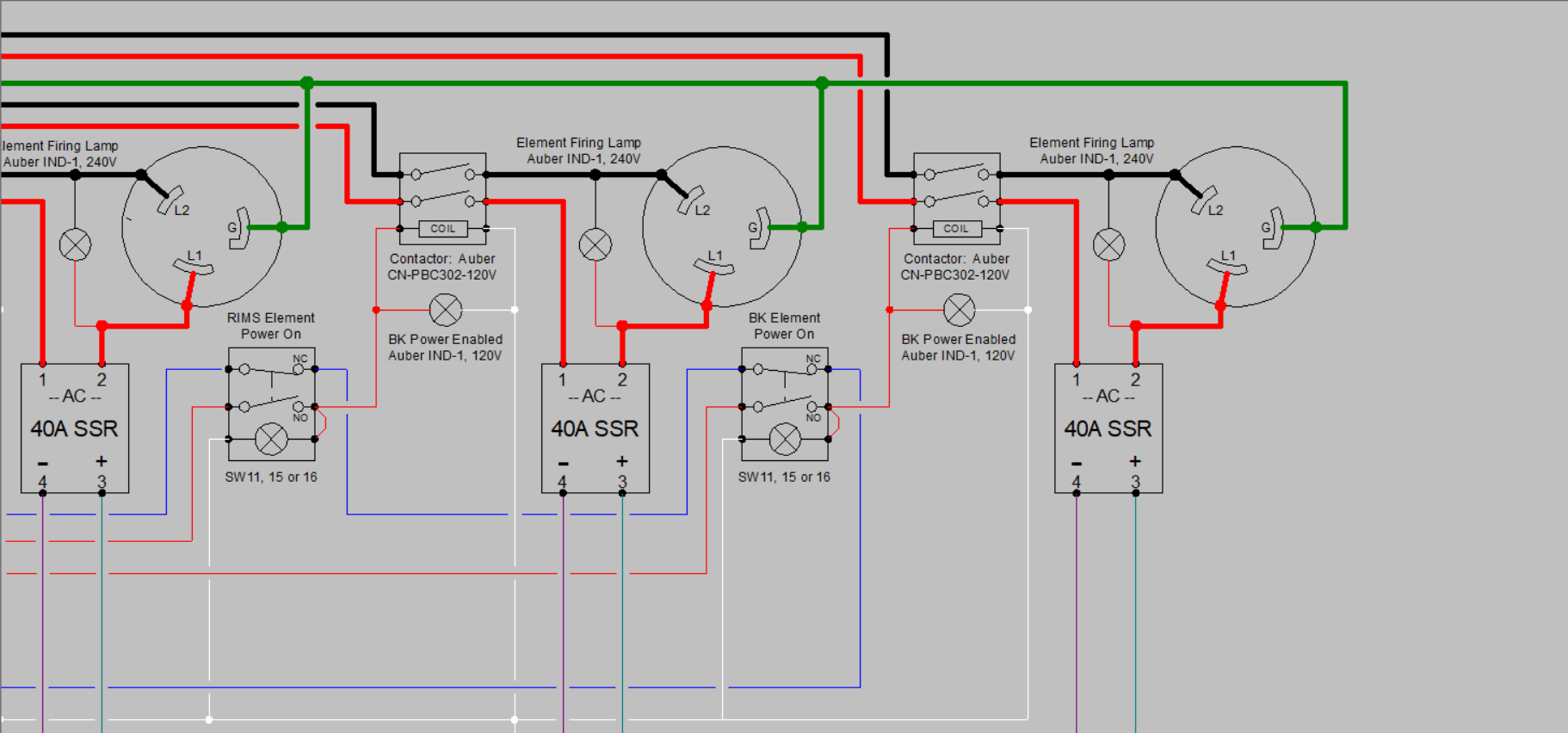

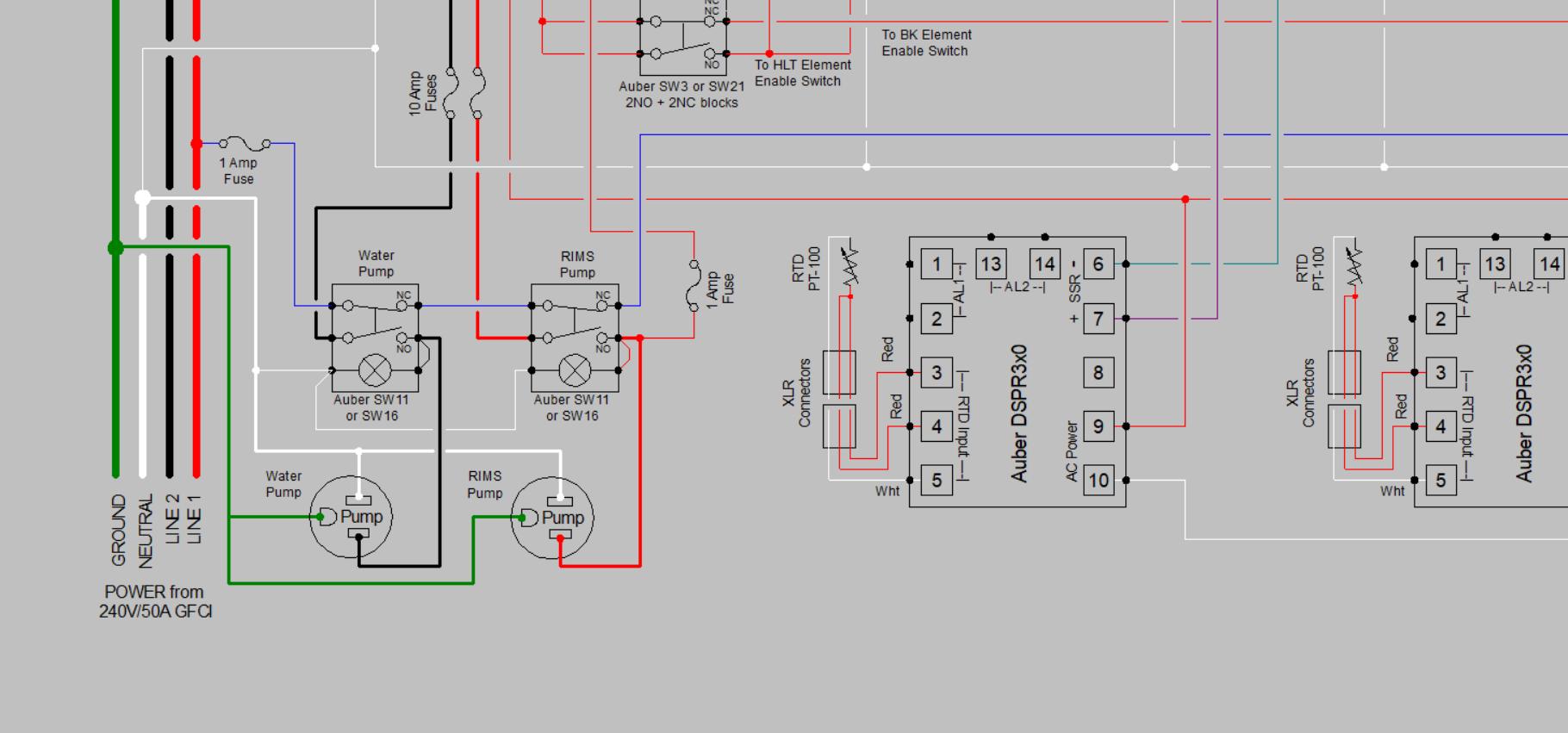

Hey y'all, well is stupid hot and I just put AC in my garage, so I'm going electric, my question is does anyone have a wiring diagram for (2) 240V element and (1) 120V element, the 240V are for the HLT and BK, and the 120V is the RIMS, my batches are 10gal, and I've looked everywhere and I can't find something similar. And I want to run the HTL and the BK at the same time, so will be a 50A panel. Thanks.