Brickout

Well-Known Member

It all started Memorial Day weekend. I spent the weekend in Wisconsin with the wife and kids. We we came home I see that my neighbor has his old freezer at the curb. So after we unpacked and settled in I went over to the neighbors house to have a beer and ask about the freezer.

So the conversation went something like this;

Me "So did your freezer die?"

neighbor "No, it's just getting old, the insulation is falling out of the lid, and we wanted a bigger one."

Me "So it still works?"

neighbor "Yeah, do you want it?"

Me" Hell YEAH!"

So that's how I got a free freezer. From inspecting it closer I believe that this freezer was built in the 70's. I noticed when I removed the access panel on the side that it had been repainted white from it's original color of AVOCADO GREEN! Then came the planing on how to turn it into a keezer.

Here you can see the thin metal lid. The inside of the lid is in the background to the right leaning against the wall.

Here's the inside of the lid after I removed the fiberglass insulation.

Here's a closeup of the tension hinge.

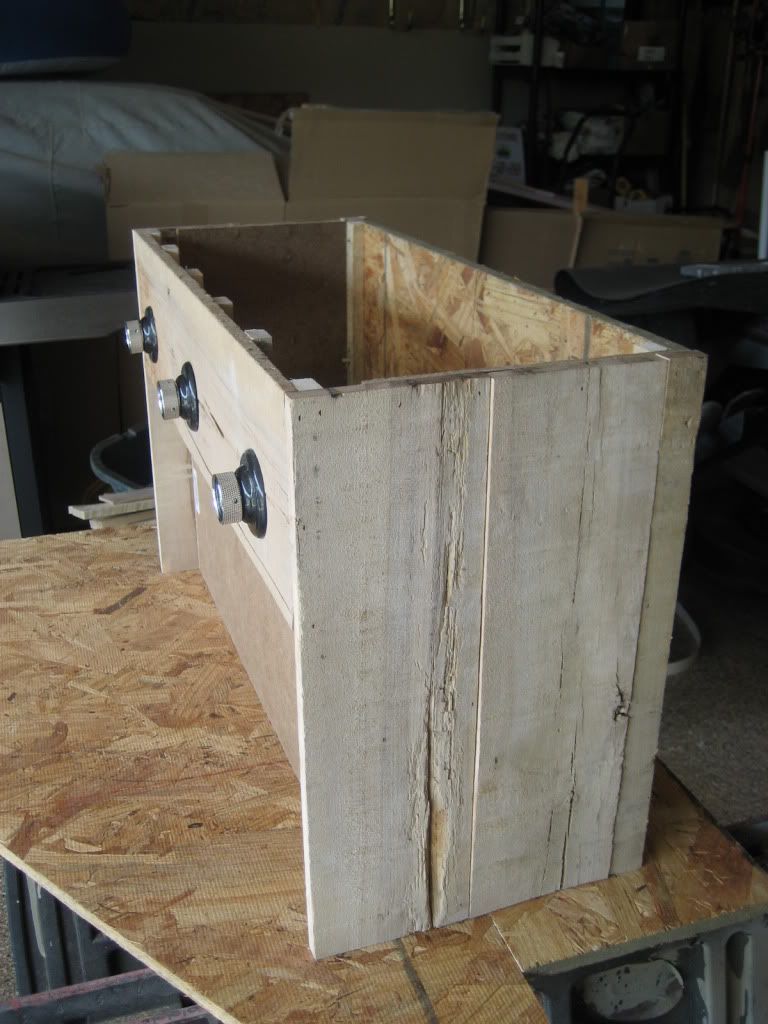

At this point I pretty much assessed that I would be making a new lid.

The next step was to make a base with some wheels. I used some scrap oak 2x4's that I had from a pallet that I took apart for another project.

I made dovetail joints for the corners then glued n' screwed them

The bottome of the freezer had some feet tack welded on,

The angle grinder made quick work of those. This allowed the freezer to sit a lot more flat and a little lower.

The next step was to assess the inside. I removed the rubber gasket which revealed some 1/4" Masonite.

I removed the Masonite to reveal the fiberglass insulation.

At this point I thought that I might be able to pull the whole tub out and replace the insulation. WRONG! Turns out that the cooling lines are welded to the tub. Luckily I didn't damage the lines.

So the conversation went something like this;

Me "So did your freezer die?"

neighbor "No, it's just getting old, the insulation is falling out of the lid, and we wanted a bigger one."

Me "So it still works?"

neighbor "Yeah, do you want it?"

Me" Hell YEAH!"

So that's how I got a free freezer. From inspecting it closer I believe that this freezer was built in the 70's. I noticed when I removed the access panel on the side that it had been repainted white from it's original color of AVOCADO GREEN! Then came the planing on how to turn it into a keezer.

Here you can see the thin metal lid. The inside of the lid is in the background to the right leaning against the wall.

Here's the inside of the lid after I removed the fiberglass insulation.

Here's a closeup of the tension hinge.

At this point I pretty much assessed that I would be making a new lid.

The next step was to make a base with some wheels. I used some scrap oak 2x4's that I had from a pallet that I took apart for another project.

I made dovetail joints for the corners then glued n' screwed them

The bottome of the freezer had some feet tack welded on,

The angle grinder made quick work of those. This allowed the freezer to sit a lot more flat and a little lower.

The next step was to assess the inside. I removed the rubber gasket which revealed some 1/4" Masonite.

I removed the Masonite to reveal the fiberglass insulation.

At this point I thought that I might be able to pull the whole tub out and replace the insulation. WRONG! Turns out that the cooling lines are welded to the tub. Luckily I didn't damage the lines.