NOT pictured: RIMS Tube, PID, SSR, and heat sink....

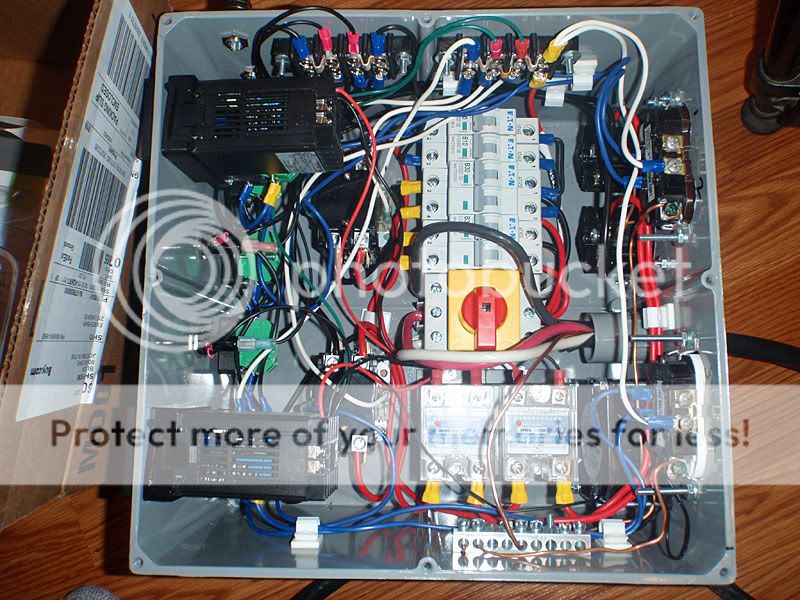

I recently built this "RIMS box" to get the hang of using a PID and the RIMS first. I will install the RIMS tube on the stand and the components in the control box.

Thanks to Tiber for the project box!

A HUGE - LARGE - BIG THANK YOU to Paul Muth (P-J) fir all of his help so far!! Here is a parts list he put together! If someone knows how to display it open (without having to use the link) please let me know. I also have it in a Excel spreadsheet.

file:///Users/robmay44/Library/Mail%20Downloads/Rob-May-Parts-List-2.htm

EDIT: Link not working right see below.

I recently built this "RIMS box" to get the hang of using a PID and the RIMS first. I will install the RIMS tube on the stand and the components in the control box.

Thanks to Tiber for the project box!

A HUGE - LARGE - BIG THANK YOU to Paul Muth (P-J) fir all of his help so far!! Here is a parts list he put together! If someone knows how to display it open (without having to use the link) please let me know. I also have it in a Excel spreadsheet.

file:///Users/robmay44/Library/Mail%20Downloads/Rob-May-Parts-List-2.htm

EDIT: Link not working right see below.