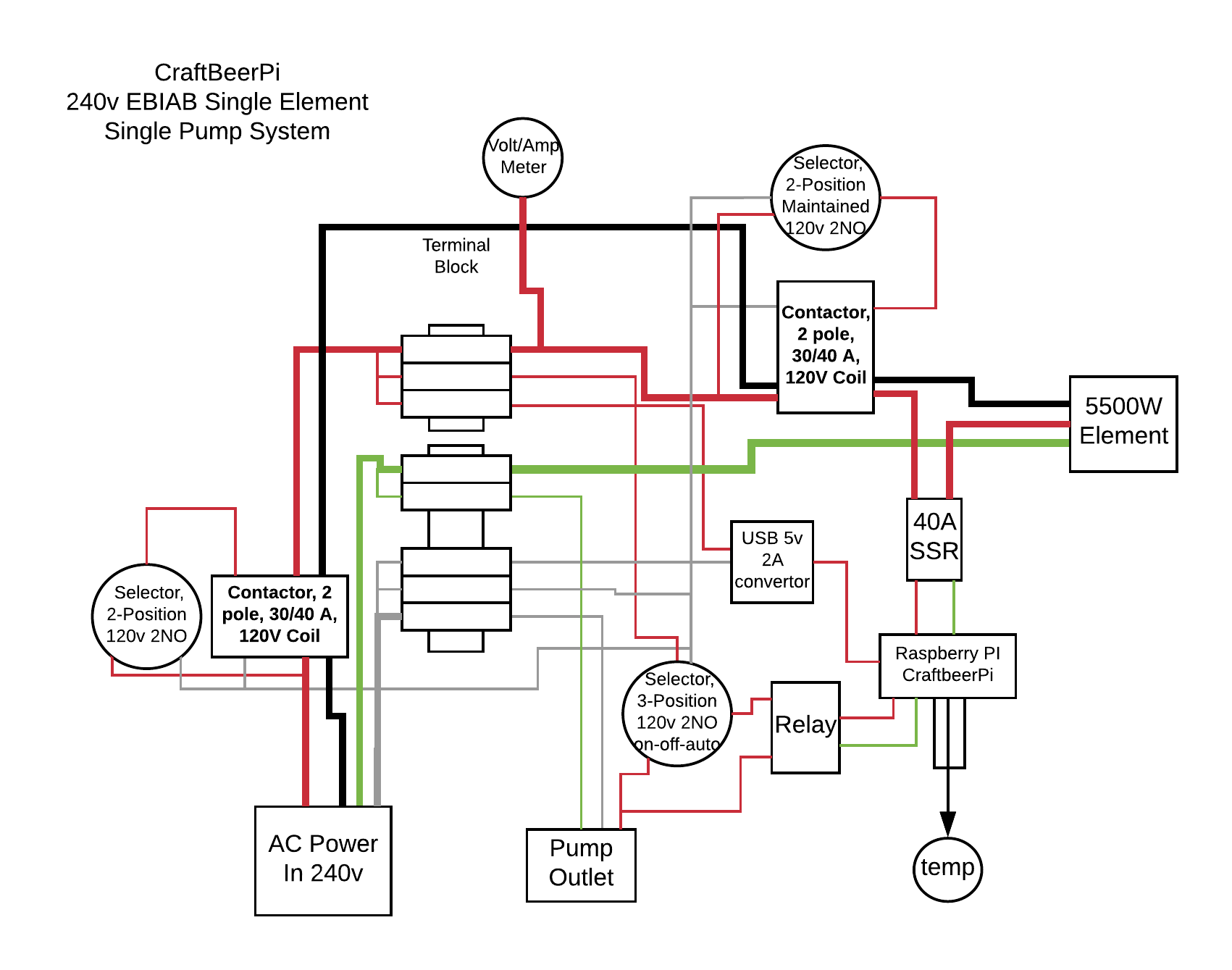

Short answer: no.

Long answer: If you connect a 120V LED from the load wire (switched) from the SSR, when the SSR is off, then the LED will be in series with the 10.5 ohm element, connected between the unswitched hot wire (black) and neutral. Thus the LED will have almost 120V across it and light up at close to max brightness whether the SSR is firing or not. Read

this post about how SSR's function to get a better understanding of what is going on.

If you test the system with the element disconnected, the "Element Firing" LED will light up dimly when the "Element Enable" contactor is activated, and the SSR is

not being triggered on. This is due to leakage thru the SSR. When the SSR is being triggered, the LED will light up fully. This "lit when off" behavior will not occur when the element is connected. Again the post linked in the previous paragraph will help understand this situation (once you understand that post.)

Brew on