Hey all!

I currently have a 10 gallon BIAB propane-fired setup (20 gallon pot, 4 1.5" TC fittings, stainless basket, center-inlet chugger pump) but haven't been super satisfied with the mash temp control, even with insulation/etc. Consequently, I have been tossing the idea around of some automated temperature control. As I am currently renting and don't have easy access to a 240V source, my main options are adding on 120V RIMS to automating the propane burner/etc. Given that I ultimately want to move to a full eBIAB setup, I was leaning towards the RIMS option.

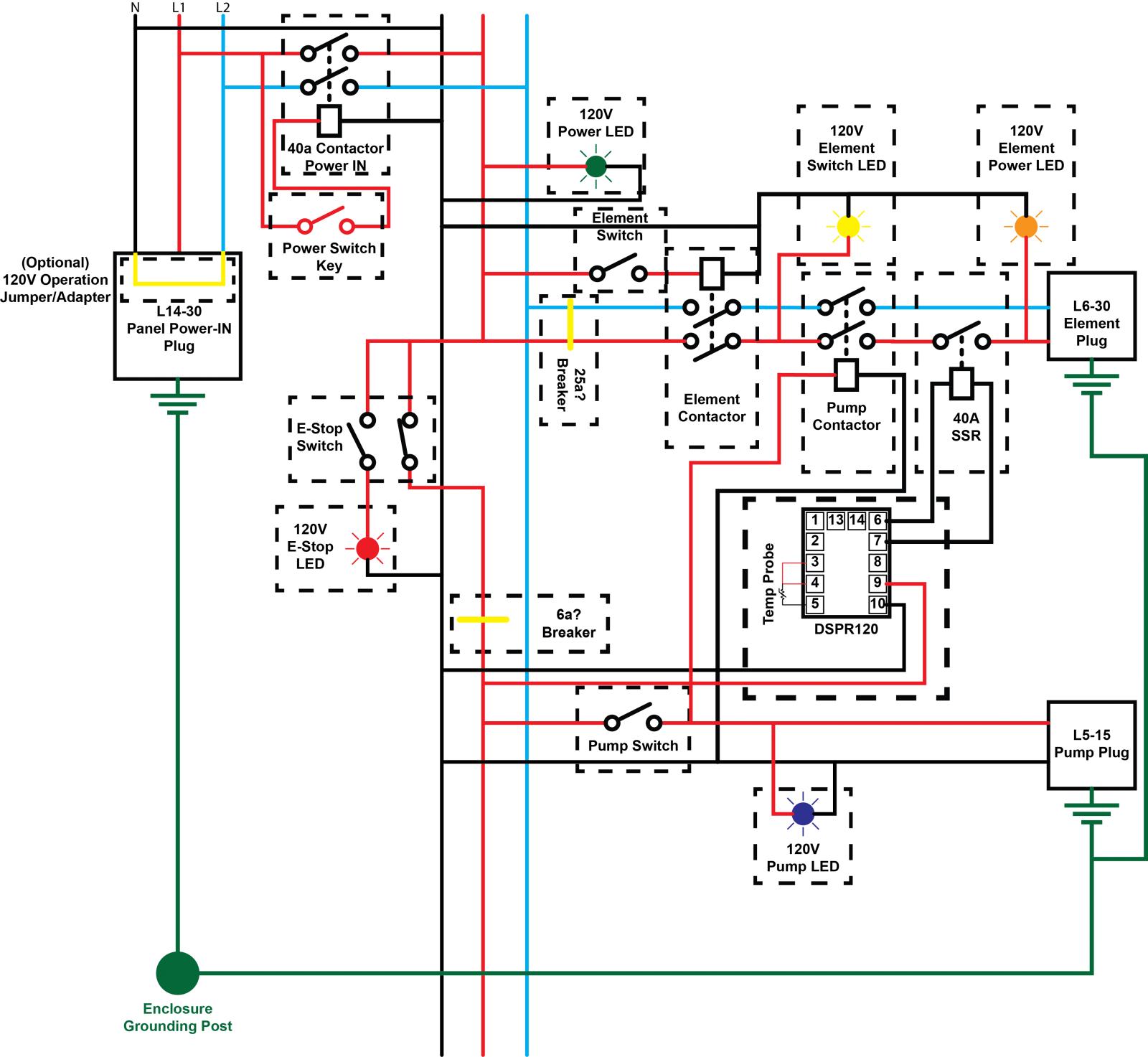

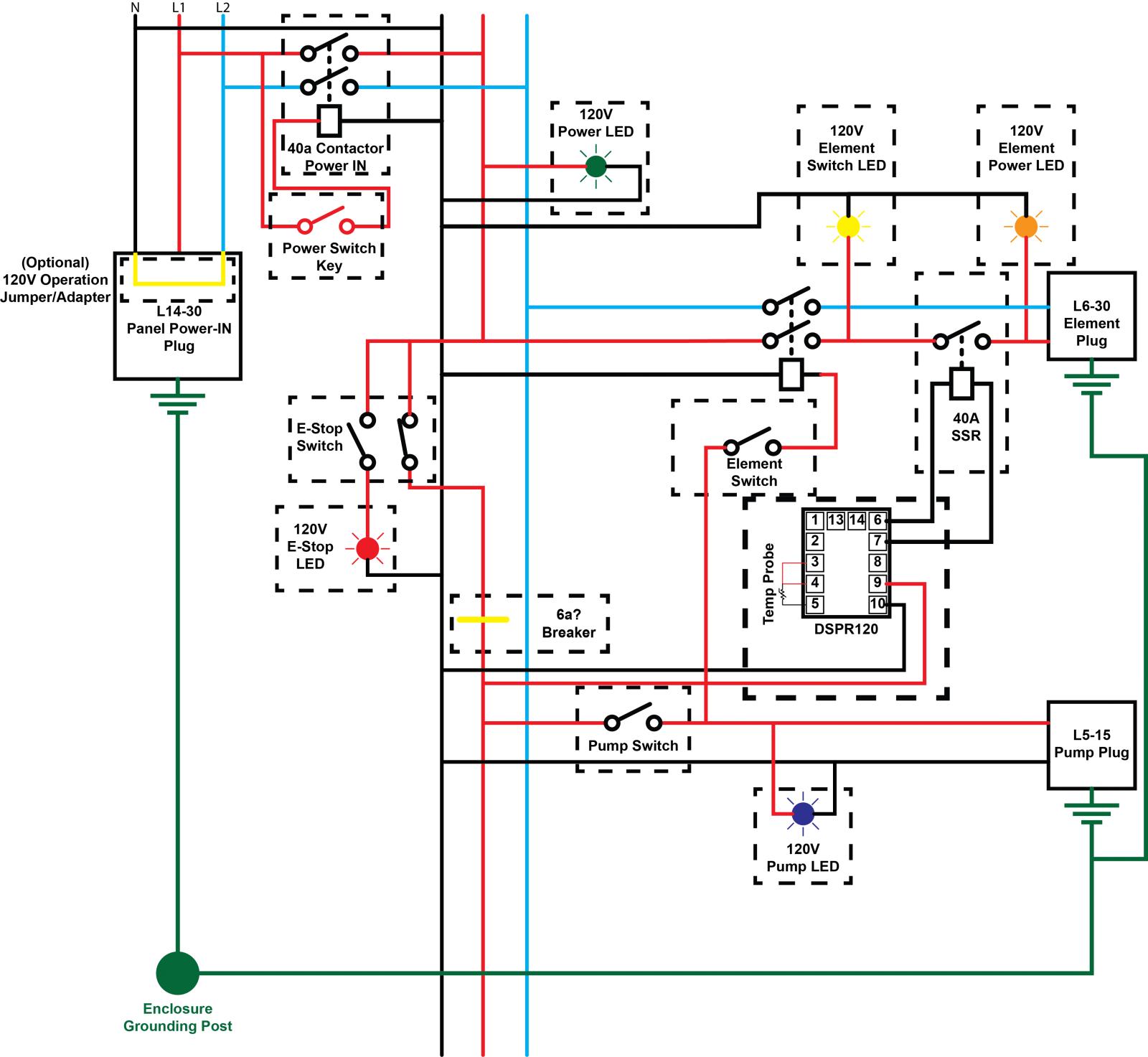

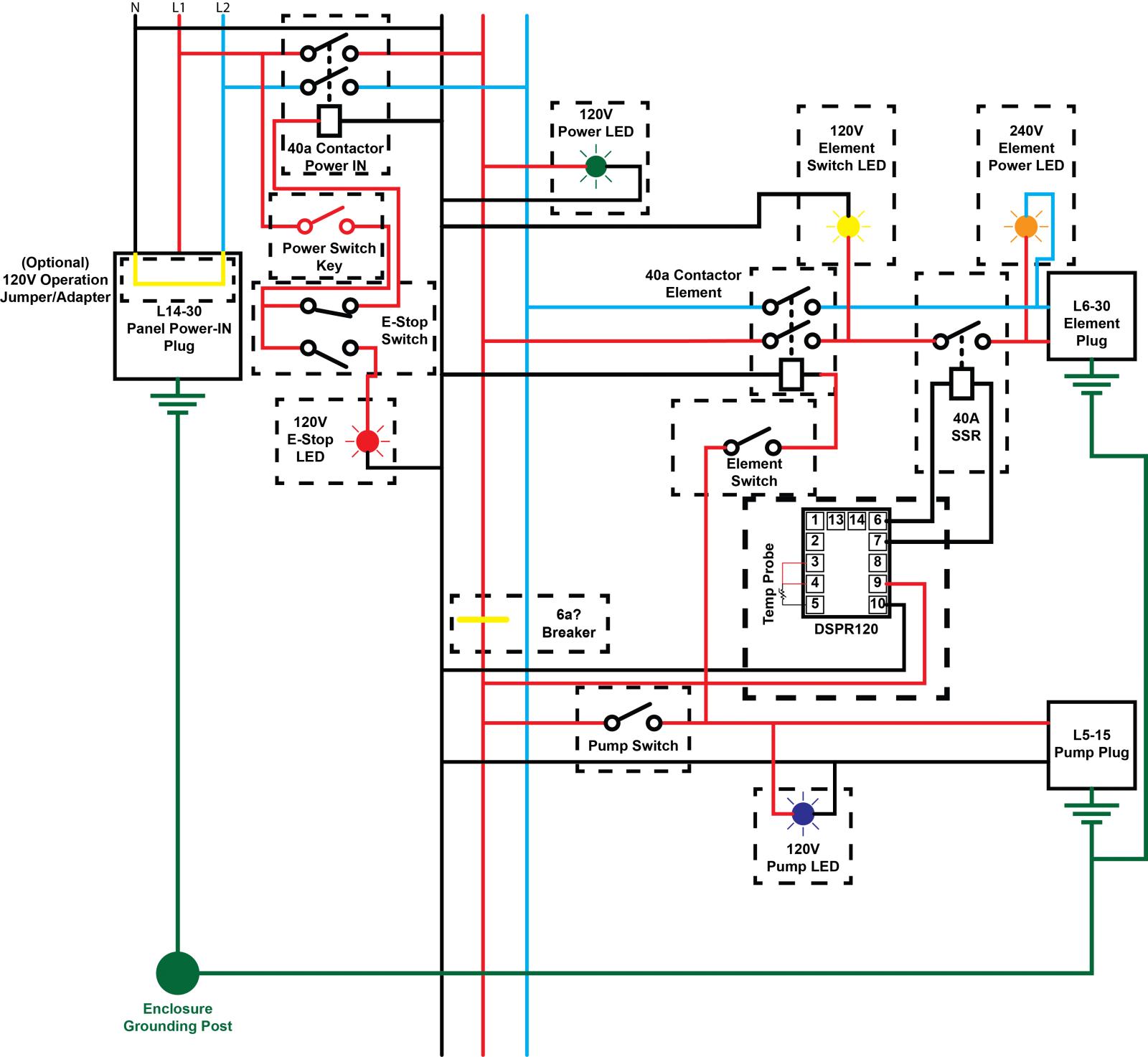

My plan is to "overbuild" my 120V controller with parts, plugs, etc that will be transferable to a full 240V eBIAB build in the semi-near future. In my understanding, this essentially means buying a 40a SSR, 40a contactors, and higher rated plugs/receptacles/etc.

I would be basing my parts list/wiring on the kits/diagrams available on ebrew supply, essentially combining the 1 element/120V/20a plans (http://www.ebrewsupply.com/1-pid-20a-120v-rims-kit/) with the 1 element/240v/30a plans (http://www.ebrewsupply.com/1-pid-30a-biab-kit/) as a starting point. I would be looking to modifying the wiring slightly to only run one pump (as I only have one and anticipate only having one since I am going to stick to BIAB), and maybe add in an additional safeguard for the RIMS setup of only allowing the element to fire when the pump is running.

I am working on preliminary parts lists/diagrams but will likely be basing the build around the brewershardware 1.5" TC RIMS tube, 5500W foldback element (to be run @ 120V for RIMS and @ 240V when I move to eBIAB), Auber 1.5" TC RTD Temperature Sensor, and EZBoil DSP120.

I just wanted to reach out and see if anybody has attempted anything similar (a "future-proof" setup) or if there is any general advice/diagrams out there for something similar?

Additionally, as I am working on my parts list, does anyone have suggestions of retailers to look at? I am going to be comparing between amazon/Ebrew Supply/Auber/potentially EBay/Local stores for electrical components and Brew Hardware/Brewers Hardware/ProFlow/etc for other hardware/components.

Thanks!

I currently have a 10 gallon BIAB propane-fired setup (20 gallon pot, 4 1.5" TC fittings, stainless basket, center-inlet chugger pump) but haven't been super satisfied with the mash temp control, even with insulation/etc. Consequently, I have been tossing the idea around of some automated temperature control. As I am currently renting and don't have easy access to a 240V source, my main options are adding on 120V RIMS to automating the propane burner/etc. Given that I ultimately want to move to a full eBIAB setup, I was leaning towards the RIMS option.

My plan is to "overbuild" my 120V controller with parts, plugs, etc that will be transferable to a full 240V eBIAB build in the semi-near future. In my understanding, this essentially means buying a 40a SSR, 40a contactors, and higher rated plugs/receptacles/etc.

I would be basing my parts list/wiring on the kits/diagrams available on ebrew supply, essentially combining the 1 element/120V/20a plans (http://www.ebrewsupply.com/1-pid-20a-120v-rims-kit/) with the 1 element/240v/30a plans (http://www.ebrewsupply.com/1-pid-30a-biab-kit/) as a starting point. I would be looking to modifying the wiring slightly to only run one pump (as I only have one and anticipate only having one since I am going to stick to BIAB), and maybe add in an additional safeguard for the RIMS setup of only allowing the element to fire when the pump is running.

I am working on preliminary parts lists/diagrams but will likely be basing the build around the brewershardware 1.5" TC RIMS tube, 5500W foldback element (to be run @ 120V for RIMS and @ 240V when I move to eBIAB), Auber 1.5" TC RTD Temperature Sensor, and EZBoil DSP120.

I just wanted to reach out and see if anybody has attempted anything similar (a "future-proof" setup) or if there is any general advice/diagrams out there for something similar?

Additionally, as I am working on my parts list, does anyone have suggestions of retailers to look at? I am going to be comparing between amazon/Ebrew Supply/Auber/potentially EBay/Local stores for electrical components and Brew Hardware/Brewers Hardware/ProFlow/etc for other hardware/components.

Thanks!