jjkeegan86

Super Bit Brewing

- Joined

- Jul 31, 2014

- Messages

- 88

- Reaction score

- 21

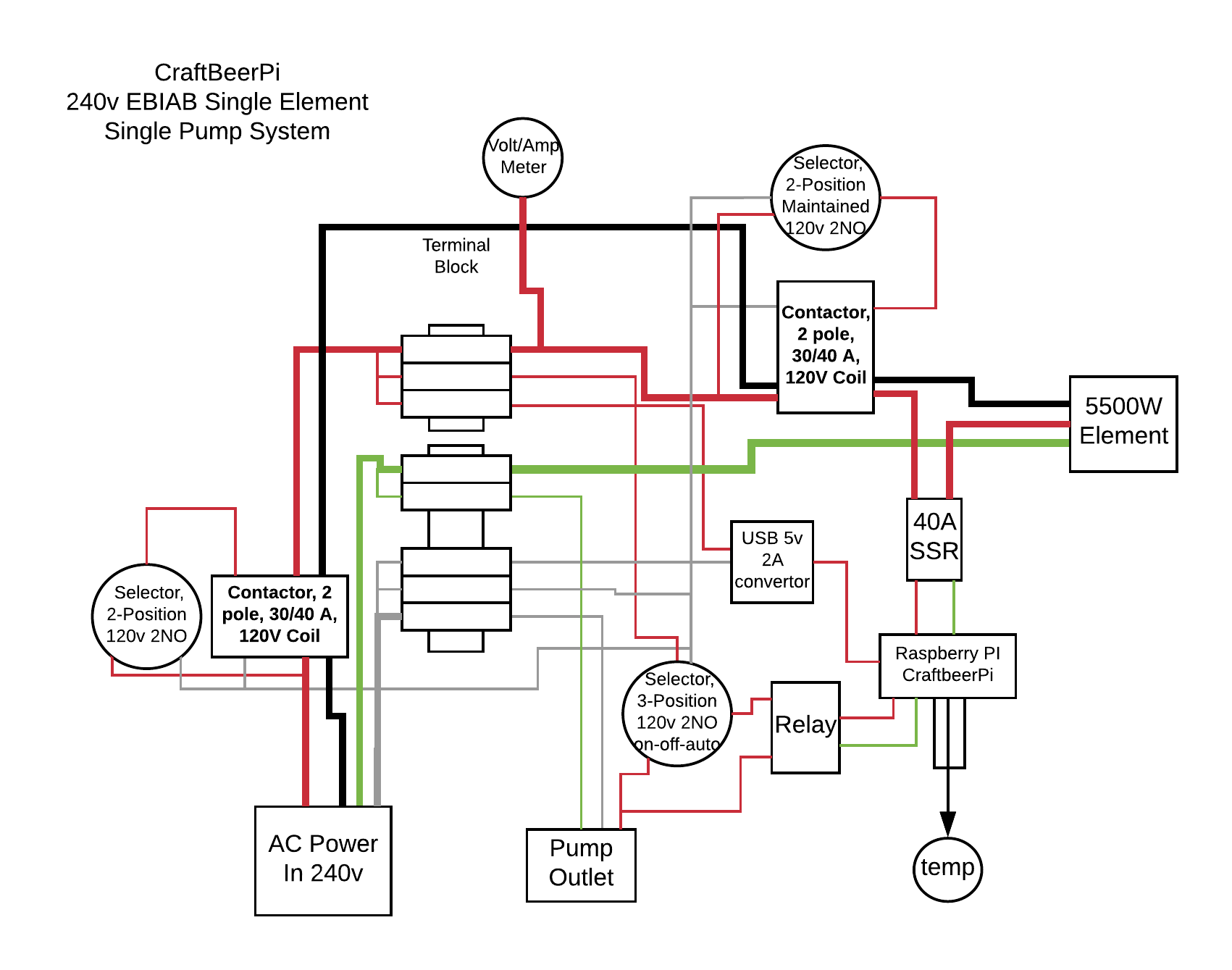

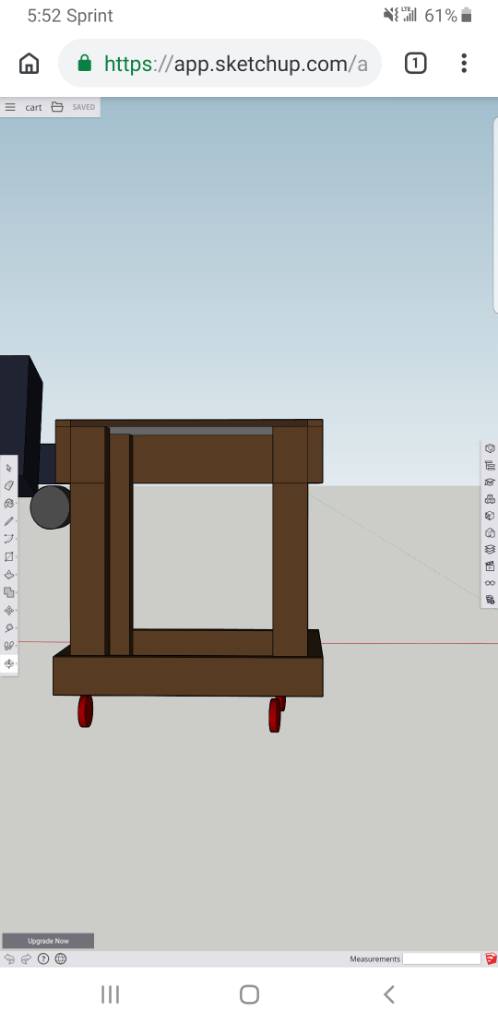

Making the move to electric. I have a 3 vessel keggle setup, but I need to shrink my brewing footprint. I toyed with keeping one keggle and adding a rims tube for mashing and then gas firing one keggle. But decided to go to a full ebiab setup. I've got a spike kettle on order and want to get started on a control panel.

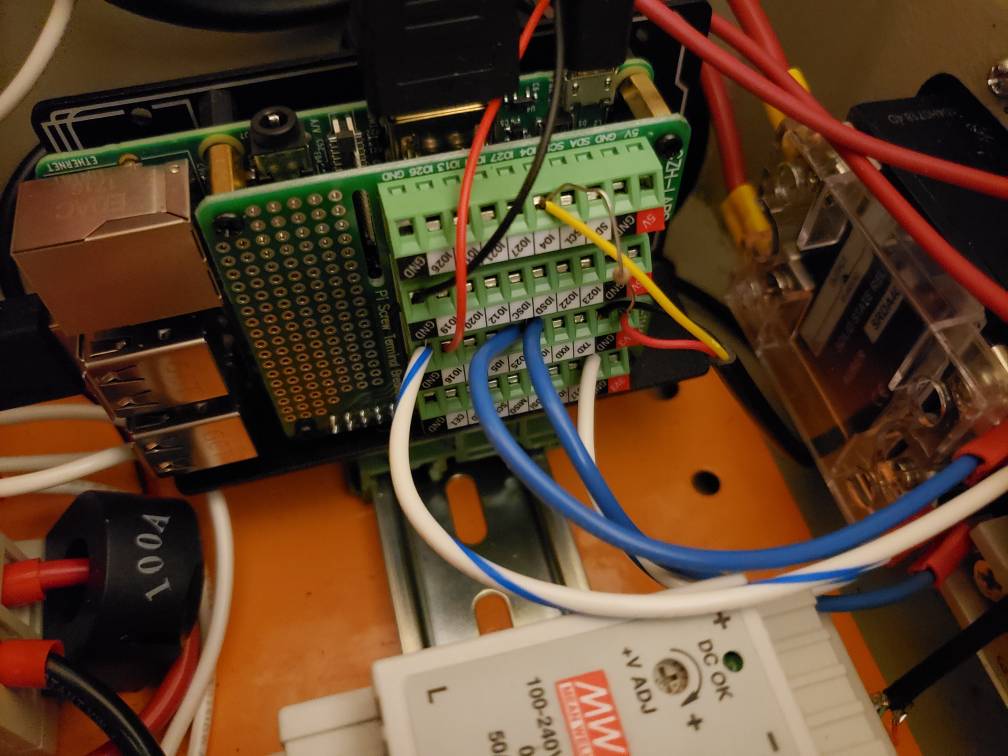

I'll be using craftbeerpi instead of pids. I already have the raspberry pi.

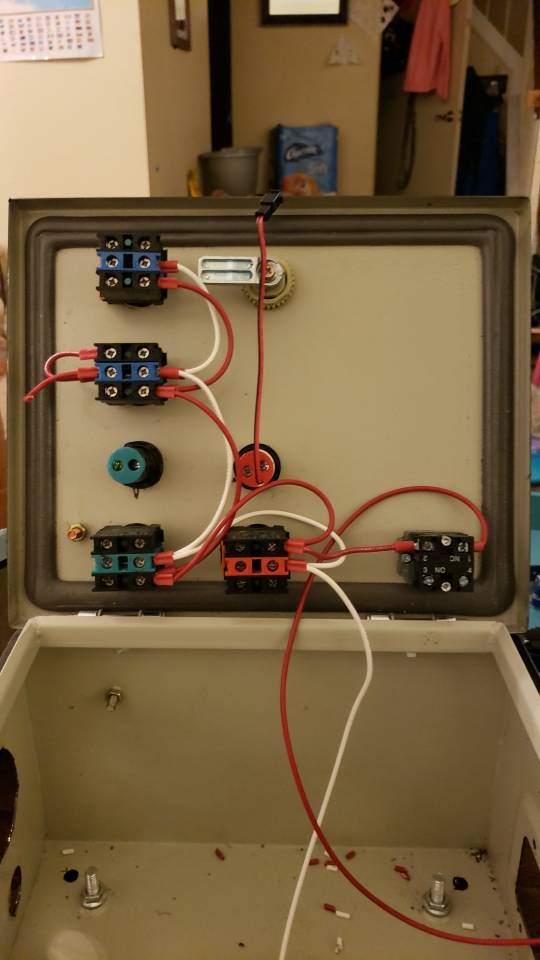

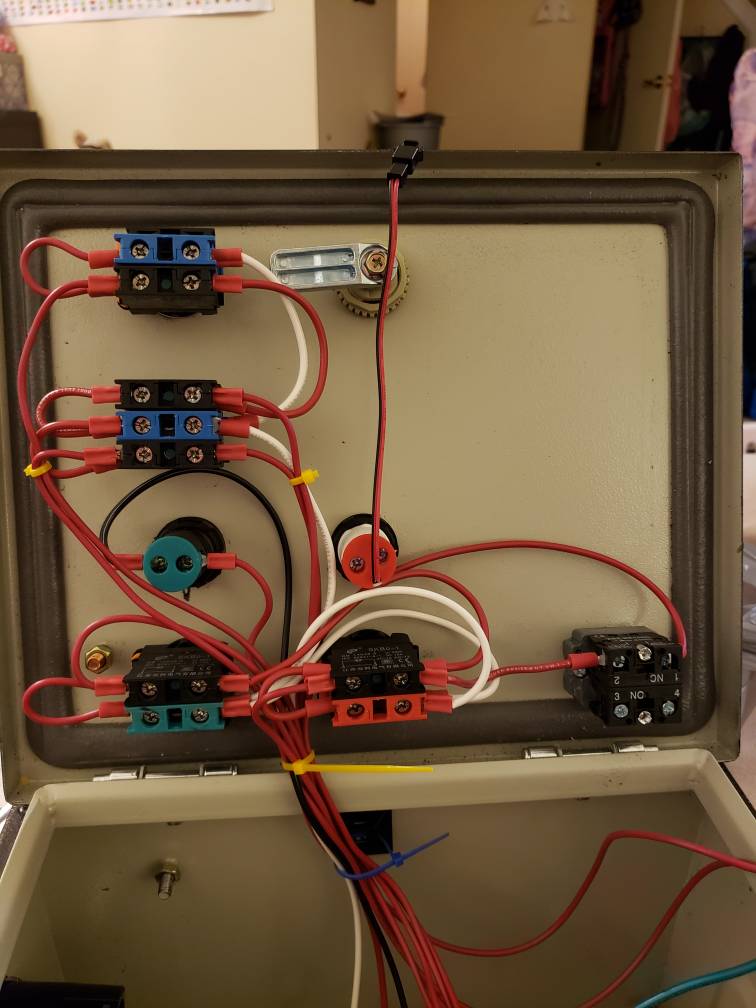

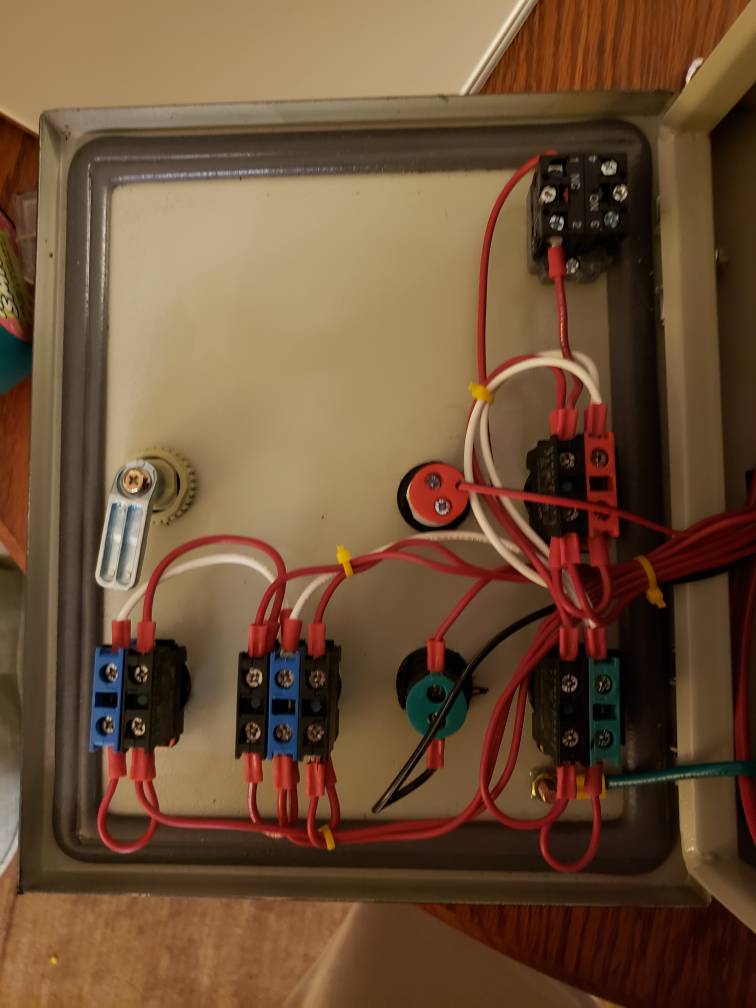

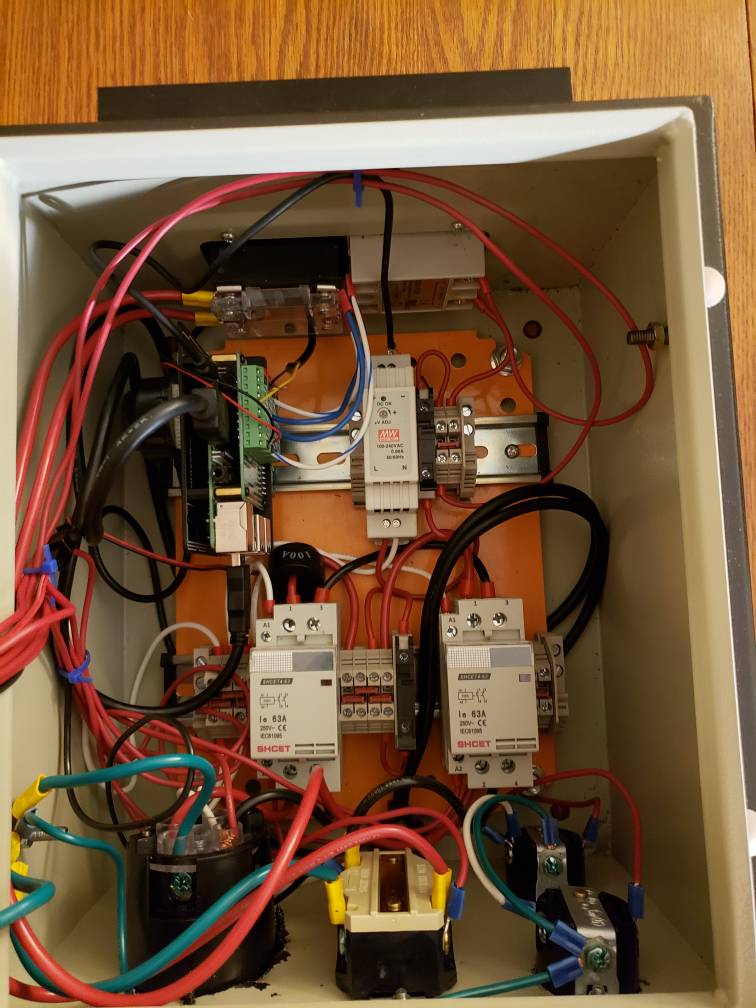

I've attached a wiring diagram and the control box part list. I'm not sure about the enclosure. Didn't know if there was a reason not to go with plastic. Also not sure how to wire an on-off-auto switch for the pump. The way I have it does not seem right. Is there any reason to avoid using an ssr for a chugger pump? I could use a regular relay if needed.

Obligatory, yes this will be on a 30 amp GFCI breaker.

Any and all feed back is appreciated!

Partlist

I'll be using craftbeerpi instead of pids. I already have the raspberry pi.

I've attached a wiring diagram and the control box part list. I'm not sure about the enclosure. Didn't know if there was a reason not to go with plastic. Also not sure how to wire an on-off-auto switch for the pump. The way I have it does not seem right. Is there any reason to avoid using an ssr for a chugger pump? I could use a regular relay if needed.

Obligatory, yes this will be on a 30 amp GFCI breaker.

Any and all feed back is appreciated!

Partlist

Last edited: