You'd be selecting out the least flocculant cells if you harvest from secondary, so you want to avoid that.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yeast Washing Illustrated

- Thread starter Bernie Brewer

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

If you do primary/secondary, consider that harvesting from primary leaves some of the highest attenuating cells behind, and you keep the highest flocculating population. Which do you prefer?

Think about harvesting from your starter - then you have all the flocculating and attenuating cells...

Think about harvesting from your starter - then you have all the flocculating and attenuating cells...

+1

And they haven't gone through as hard a battle with trying to ferment a full gravity wort

Quickly, before zee Germans get 'ere...

Safa

Well-Known Member

Made a rookie mistake. Didn't have time to do full wash, so just threw the slurry into two mason jars.

Left to settle over the weekend, decanted beer off, filled up with water and let it settle again for a few days.

Went back today to do actual wash + separate from trub, damn jars smelled sour and rancid.

Sanitation fail!

Really hoping that the infection wasn't present before I started my modified-lazy-man-wash.

Left to settle over the weekend, decanted beer off, filled up with water and let it settle again for a few days.

Went back today to do actual wash + separate from trub, damn jars smelled sour and rancid.

Sanitation fail!

Really hoping that the infection wasn't present before I started my modified-lazy-man-wash.

What water did you use?

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

jwalker1140

Well-Known Member

Bummer about the infection. My two cents: get your sanitation practices dialed in. Certainly. But then you may want to read the first post in each of these threads before you give washing another go:Made a rookie mistake. Didn't have time to do full wash, so just threw the slurry into two mason jars.

Left to settle over the weekend, decanted beer off, filled up with water and let it settle again for a few days.

Went back today to do actual wash + separate from trub, damn jars smelled sour and rancid.

Sanitation fail!

Really hoping that the infection wasn't present before I started my modified-lazy-man-wash.

https://www.homebrewtalk.com/f163/cold-hard-truth-about-rinsing-yeast-boiled-water-451925/

https://www.homebrewtalk.com/f163/why-not-pitch-your-yeast-cake-166221/

I assume your slurry smelled fine when you decanted off the beer and didn't smell rancid until after a few days under water?

Safa

Well-Known Member

Used tap water (first fail)

Didn't starsan the lids (second fail)

Thanks will check articles, and yes you are correct that the smell only appeared after a few days under water.

Didn't starsan the lids (second fail)

Thanks will check articles, and yes you are correct that the smell only appeared after a few days under water.

drumuglyknuckles

Well-Known Member

- Joined

- Sep 17, 2013

- Messages

- 143

- Reaction score

- 6

Thanks Bernie, good write up!

Sent from my GT-I9100 using Home Brew mobile app

Sent from my GT-I9100 using Home Brew mobile app

Start with this - http://www.mrmalty.com/calc/calc.html

Use the repitching from slurry tab. Let me know what confuses you because I'm sure it will be something

Use the repitching from slurry tab. Let me know what confuses you because I'm sure it will be something

Just a note, I tried using yeast that I washed 5 months ago, and it did not work. After 24 hours there was no sign of fermentation.

Thoughts as to why?? Jus to long between activity?

I may have lost power, but my starters for my washed Kolsch and Dry English ale yeasts (for a smoke porter) are humming along nicely. Gawd, I live brewing beer!!

And I just had a starter bubble for 2 days using 3.5 month old rinsed yeast.Just a note, I tried using yeast that I washed 5 months ago, and it did not work. After 24 hours there was no sign of fermentation.

catdaddy66

Well-Known Member

How does one go about harvesting yeast from a commercial bottled beer? I'm trying to clone a favorite but not sure how, or how long to step up to a proper amount for fermenting 5-6 gallons.

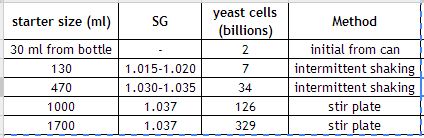

Here's what I've done:

*Chill the can or bottle at least overnight. This will help compact most of the the yeast at the bottom so you can keep it on the bottom as you pour out the beer.

*Make starter and cool (see table below for step sizes I used).

*Slowly pour the beer into a glass leaving some beer/yeast in the bottle/can.

*Swirl the can/bottle and pour the remaining liquid into your starter and aerate.

*Loosely cover and place in a warm location.

*Shake intermittently, I do not use a stir plate on my first two steps to keep growth rates controlled. *Depending on the age of the yeast, it could take anywhere from 1 to 4 days for you to see any signs of fermentation. If you don't see anything after 4 days, raise the temp to 70-75 degrees, shake hard, and let it sit 24 hours. At that point, the yeast usually kicks into action and you might see some yeast rafts in the middle of the wort and a tiny bit of krausen. If you still don't see anything, try proceeding to the next step anyway.

*Repeat steps making bigger and bigger starter to grow the yeast to a pitchable quantity.

*Let each step ferment for 2 days.

*If you have a big enough container, you can pour the current step into the next step (this is preferred).

*If you get to a size where you can't do that, chill your starter in the fridge for 2 days. Remove from fridge and decant the clear liquid on the top leaving a little behind. Swirl the container to get the yeast into suspension and all to warm up to the temp of the next step and then pitch that.

Here are the step sizes I used:

*Chill the can or bottle at least overnight. This will help compact most of the the yeast at the bottom so you can keep it on the bottom as you pour out the beer.

*Make starter and cool (see table below for step sizes I used).

*Slowly pour the beer into a glass leaving some beer/yeast in the bottle/can.

*Swirl the can/bottle and pour the remaining liquid into your starter and aerate.

*Loosely cover and place in a warm location.

*Shake intermittently, I do not use a stir plate on my first two steps to keep growth rates controlled. *Depending on the age of the yeast, it could take anywhere from 1 to 4 days for you to see any signs of fermentation. If you don't see anything after 4 days, raise the temp to 70-75 degrees, shake hard, and let it sit 24 hours. At that point, the yeast usually kicks into action and you might see some yeast rafts in the middle of the wort and a tiny bit of krausen. If you still don't see anything, try proceeding to the next step anyway.

*Repeat steps making bigger and bigger starter to grow the yeast to a pitchable quantity.

*Let each step ferment for 2 days.

*If you have a big enough container, you can pour the current step into the next step (this is preferred).

*If you get to a size where you can't do that, chill your starter in the fridge for 2 days. Remove from fridge and decant the clear liquid on the top leaving a little behind. Swirl the container to get the yeast into suspension and all to warm up to the temp of the next step and then pitch that.

Here are the step sizes I used:

milldoggy

Well-Known Member

Did you rinse it?

No, I was trying the no rinse approach

methusula110

Well-Known Member

I was inspired by this thread to give rinsing/harvesting yeast a try (I harvested this batch of WLP002 yesterday). I'm sorry if this has been answered, but the thread is 200 pages +. Please tell me if i have this right, I included some pics of my harvest

1. As long as I use the yeast within one week I can pitch it directly (after bringing it to room temp) into the cooled wort

2. If I use it within two weeks, I need to add some wort or DME to wake up yeast and pitch

3. After two weeks a starter will be required

1. As long as I use the yeast within one week I can pitch it directly (after bringing it to room temp) into the cooled wort

2. If I use it within two weeks, I need to add some wort or DME to wake up yeast and pitch

3. After two weeks a starter will be required

darknight3684

Member

- Joined

- Jan 27, 2014

- Messages

- 5

- Reaction score

- 0

I sooo needed this!!! Thanks!!!

Sent from my SAMSUNG-SM-N900A using Home Brew mobile app

Sent from my SAMSUNG-SM-N900A using Home Brew mobile app

What's the difference between 2 and 3?I was inspired by this thread to give rinsing/harvesting yeast a try (I harvested this batch of WLP002 yesterday). I'm sorry if this has been answered, but the thread is 200 pages +. Please tell me if i have this right, I included some pics of my harvest

1. As long as I use the yeast within one week I can pitch it directly (after bringing it to room temp) into the cooled wort

2. If I use it within two weeks, I need to add some wort or DME to wake up yeast and pitch

3. After two weeks a starter will be required

I don't think 1 is universally true. When rinsing yeast, you are losing a bunch of yeast. Use Mr. Malty's calculator on the "repitching from slurry tab". You're going to have to adjust the sliders based on what you have. If you hover over the triangle slider, you will get some help. That will tell you if you have enough slurry to pitch directly.

Having said that, if you know you are going to use the same yeast within a couple weeks, don't even bother rinsing. Just harvest the slurry from the bottom into a sanitized container and refrigerate. You can use Mr Malty to get the amount to pitch, but in this case, it will most likely be a "thick slurry" but the non yeast percentage will be higher. For info on using the yeast cake, read at least the first post in this thread.

methusula110

Well-Known Member

What's the difference between 2 and 3?]I was reading from several sources and it seemed like a good average. I guess the difference (other than 7 days) is there has to be a cut off somewhere, and I'm trying to make this as simple as I can. Hopefully, after some experience I can refine the practice a little. I am planning on making high gravity brew this weekend with one of the collected jars and wanted to make see if anyone has success with pitching it straight from the jar (after brought up to room temp)

I always have a couple buckets of sanitizer around on brewday and I put my jars of yeast in one of them to equalize the temp, usually when I start chilling my wort. (Yeast is dense and the jars sink fast, so be careful not to just drop them in a 5-gal bucket if you do this).

To me making a starter is the same as adding DME, so that's why I was confused.What's the difference between 2 and 3?]

I was reading from several sources and it seemed like a good average. I guess the difference (other than 7 days) is there has to be a cut off somewhere, and I'm trying to make this as simple as I can. Hopefully, after some experience I can refine the practice a little. I am planning on making high gravity brew this weekend with one of the collected jars and wanted to make see if anyone has success with pitching it straight from the jar (after brought up to room temp)

So you said you "harvested" WLP002. Does that mean you simply scooped up some of the yeast cake from the bottom of the fermentation bucket and saved it or did you rinse it according to the original post in this thread?

Let me know the gravity of the beer you want to make and I can help you run through how to use MrMalty. I'm guessing if you rinsed, you will need to make a starter and if you just harvested the yeast cake, you won't.

methusula110

Well-Known Member

Matt, I rinsed it according to the original post. However, I split the batch in thirds rather than fourths. I'm going for a 1.075 OG.

I always harvest from the top crop on my ales. I do not have a fridge so I don't do many lager beers except for winter when I can use nature. On the 3rd day of fermentation I check the krausen and if of looks good then I boil a couple jars, lids, and a stainless spoon. I make sure some of the boiled water is in each jar, cool it down, and use the spoon to scrape yeast from the top of the beer. I usually get a crazy amount of really healthy yeast that I can straight pitch without a starter if used within a couple weeks. I have found that if I do have to create a starter then I need something with a lot of head space because it will foam over a flask. I have a 5 liter jug that I now use for 1-2 liter starters just to be safe.

Sent from my super rad tablet device thingy.

Sent from my super rad tablet device thingy.

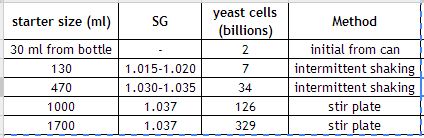

Here's what you'd enter in Mr. Malty:Matt, I rinsed it according to the original post. However, I split the batch in thirds rather than fourths. I'm going for a 1.075 OG.

I used your new OG, your harvest date and kept the default for yeast concentration and non-yeast percentage. So you need 138 ml of the slurry from the bottom of your containers. I'm going to assume you don't have enough from your pictures so I would definitely make a starter.

To estimate how much yeast you have, take the volume of yeast you have (i'm going to assume 50 ml just to give you an example) and multiply by the yeast concentration (assumed 2.4 billion/ml from Mr. Malty above).

50 ml * 2.4 b/ml = 120 billion

Multiply that by the yeast % (assumed to be 85% because 100% minus 15% default non-yeast % from Mr. Malty is 85%).

120 b * 85% = 102 billion

Then multiply by the viability - 90% based on your harvest day of 2/2/14, so

102 b * 90% = 92 billion.

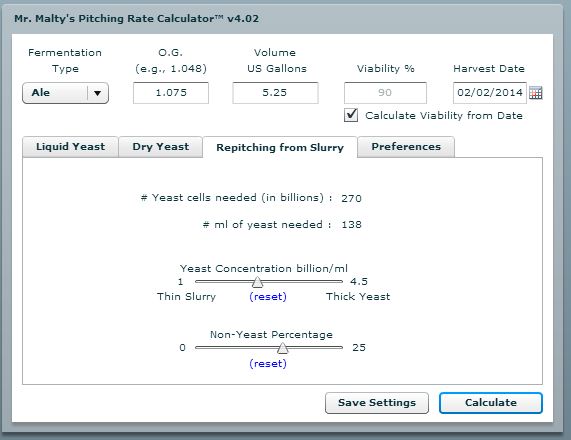

Then I'd drop that number into a yeast starter calculator like yeastcalc.com and you'd get that you need to make a 1.7L stirred starter to get the counts you need for your beer. This is what it looks like:

Obviously you need to redo the math because I just picked 50 ml of yeast slurry and you can change any of the numbers I assumed to see what you need. Hope that helps.

Similar threads

- Replies

- 36

- Views

- 2K

- Replies

- 149

- Views

- 14K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)