- Joined

- Nov 13, 2019

- Messages

- 546

- Reaction score

- 377

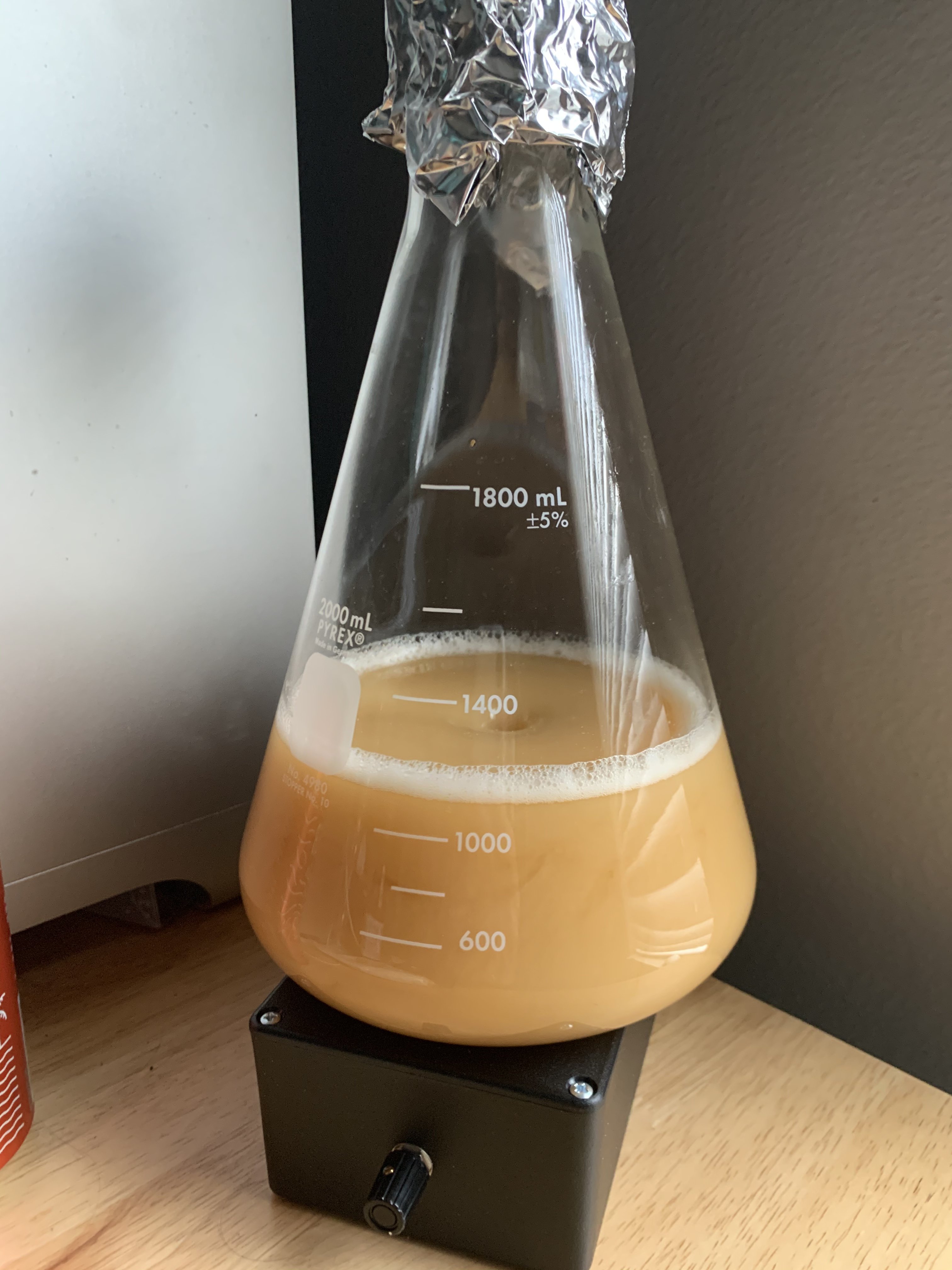

Damn I like hearing everyones method and reasons for doing what they do. Me, I get a pack of yeast and make a .8L starter for it, let it got for 24hrs then fridge and decant. Then use that to make 2L starter, run it for 24hrs and fridge and decant into a separatory flask. Once it sits for 24 in the separatory the yeast collects at the bottom and wort on top. I pull 25ml of yeast and 25ml of glycerin solution into 50ml vial and put them in alcohol to freeze slow for 24 hrs, then take them out and store in the freezer. One pack of yeast with this method lets me make about 6 packs of yeast, I dont do it to save money, i do it to have yeast on hand whenever i need it because i brew a lot at the sput of the monemt and it hasnt failed my yet. i do want a biger separatory flask though lol.

Also doing step starters vs one big starter will give you more yeast cells.

Also doing step starters vs one big starter will give you more yeast cells.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)