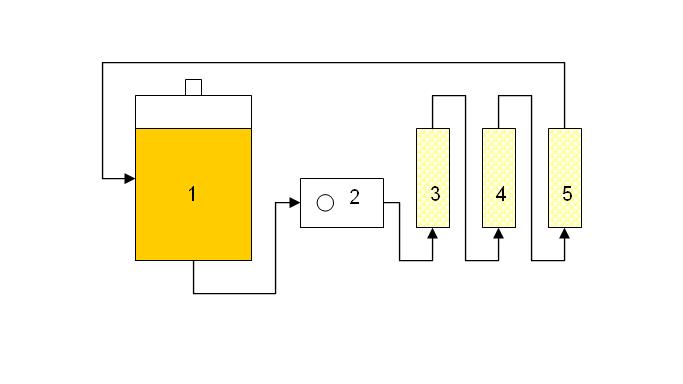

Consider the attached diagram

1) Fermenter with two hose barb attachment and airlock

2) peristaltic pump sized to provide calculated flow and pressure to 3-5

3) column with alpha amylase beads

4) column with beta galactosidase

5) column with yeast beads

-- column dimensions based on contact time, reaction rate, ability of beads to withstand flow stresses

Optional inline columns: filtering, nutrient, dry hop column, or maybe even a UV disinfection column.

Thought experiment -- if a combination of flow and column dimensions allow for a single pass, is it possible to produce a continuous flow of beer at the end of the process. This may require maintaining a volume in the 1st tank between a certain minimum/maximum level through periodic additions of fresh wort. Potential advantages to continuously brewed beer are the reduction or process down-time and cost of sanitation, a consistency of beer over a long period of time...

Just spit balling here...

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)