snowtires

Well-Known Member

- Joined

- Sep 7, 2012

- Messages

- 621

- Reaction score

- 92

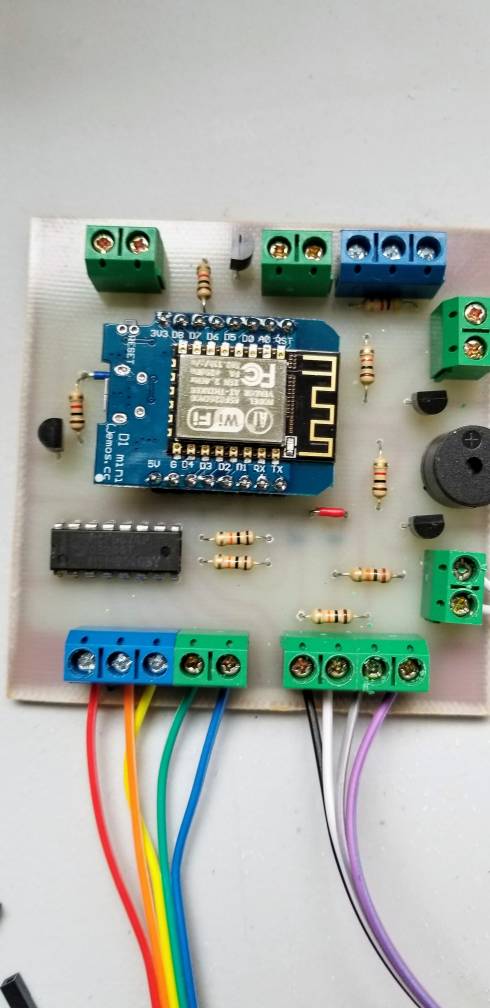

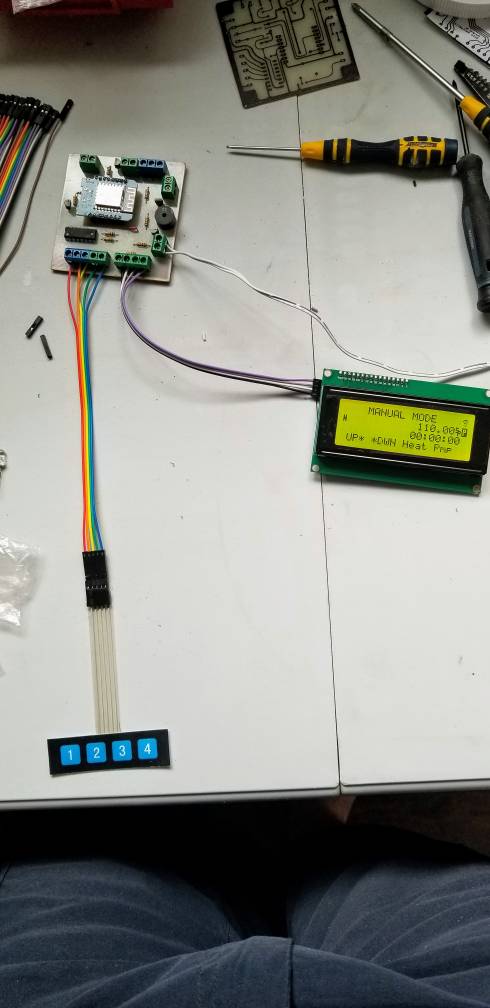

Just an update, I am finally working on the toner transfer PCB I designed to test if it works. I did the transfer the other day and I just gave it a bath in ferric chloride. I will drill holes and go nuts soldering the parts this weekend. If everything works I will release the .BMP of the printable circuit board and the component silkscreen orientations for the other side. this is a single sided board that should be fairly doable for the average DIYer.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)