Be sure to use the same pitch rate.

Yes, I will. I will probably get a cheap haemocytometer to do cell counts. It's been on the list for a while.

Be sure to use the same pitch rate.

Legend has it that the Dupont strain stalls because of the pressure produced by the airlock...but the amount of pressure that this produces is extremely negligible.

If this were the case, a weather storm would cause this yeast to stall due to pressure changes...hard to believe.

Legend has it that the Dupont strain stalls because of the pressure produced by the airlock...but the amount of pressure that this produces is extremely negligible. If this were the case, a weather storm would cause this yeast to stall due to pressure changes...hard to believe.

You might as well dump the batch right away as any oxygen you might introduce once fermentation is under way won't fix any issues you're having with it and will completely ruin your beer before it's even fully fermented.If I had a stall, I would try to agitate the fermenter, warm it up a bit, and perhaps add a bit of oxygen as long as there is still quite a bit left to ferment.

Actually the argument he made is that the yeast has to adapt to your "brew setup". He then made it pretty clear that he has no idea what that actually means.The arguments you made (adaption of the yeast from pure culture to the wort) are consistent with the published literature on yeast physiology, so the hypothesis can't simply be dismissed as one not worth testing.

You might as well dump the batch right away as any oxygen you might introduce once fermentation is under way won't fix any issues you're having with it and will completely ruin your beer before it's even fully fermented.

If this were the case, open fermentation would not be a thing. You might have a hard time convincing Anchor Brewing, Sam Smith, Schneider Weisse, among others.

If this were the case, open fermentation would not be a thing. You might have a hard time convincing Anchor Brewing, Sam Smith, Schneider Weisse, among others.

I've tried a second blast of oxygen into fermentation (no later than 24 hrs) in two circumstances. VERY strong beers (15% ABV or so).

Actually the argument he made is that the yeast has to adapt to your "brew setup". He then made it pretty clear that he has no idea what that actually means.

There is no oxygen ingress in a properly conducted open fermentation. Personally I think that the term "open fermentation" is quite misleading but as that is what the industry is using who am I to argue against that?If this were the case, open fermentation would not be a thing. You might have a hard time convincing Anchor Brewing, Sam Smith, Schneider Weisse, among others.

If throwing away a perfectly good batch of beer is a solution to you then yes, problem solved. Alternatively you could try and actually adress the issue you seem to be obviously having with your starters.Why would I fret over the details when it's problem solved?

I did say "once fermentation is under way", didn't I?This.

I've tried a second blast of oxygen into fermentation (no later than 24 hrs) in two circumstances. VERY strong beers (15% ABV or so). And lagers, if the pitching rate is less than ideal, though I don't do that unless I have no choice. In both cases, beer definitely isn't ruined.

Isn't the exchange of personal experience the very purpose of an online forum such as this? Dismissing it as purely anecdotal is certainly correct from an epistemological point of view, but it is absurd to demand scientific rigour in a discourse such as this.

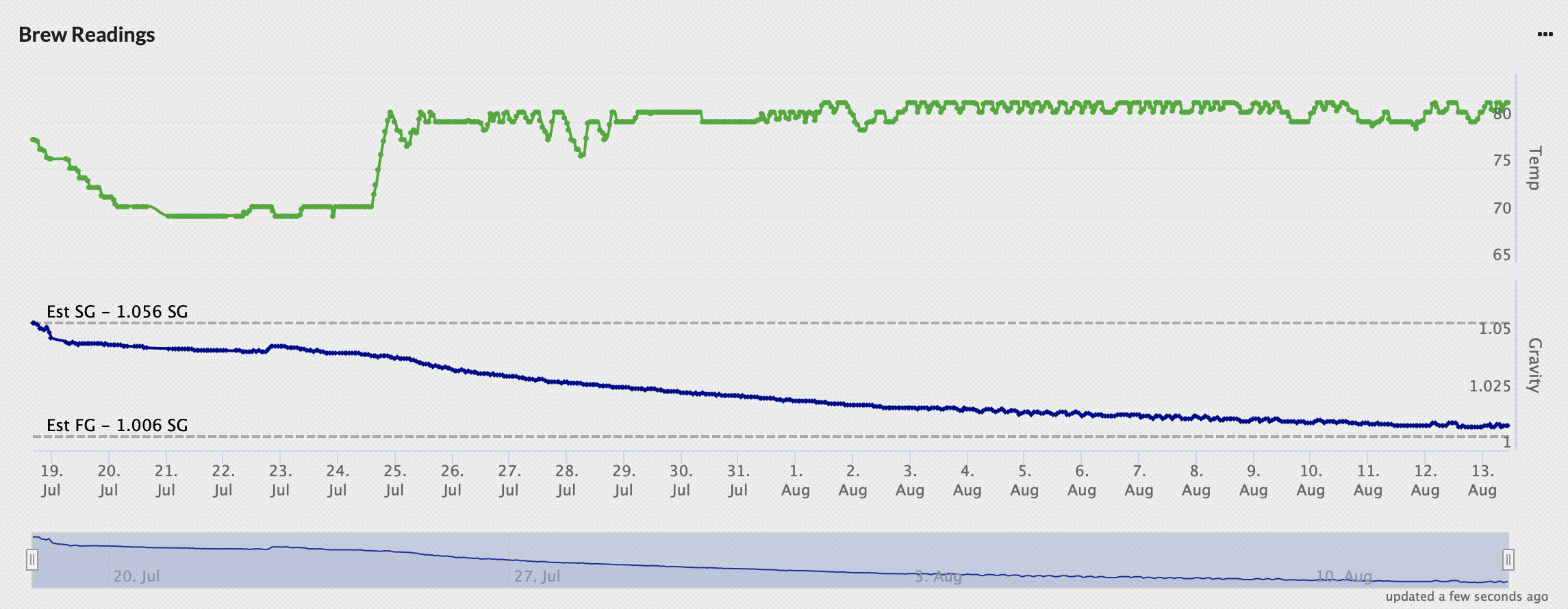

I recommend open fermentation with 3724Well this has been one long ferment. Almost a month and it's at 1.011 according to my Tilt (the fast fermentation test got to 1.003). The gravity looks like it's still slowly dropping. I think I'm going to rack to a keg with a spunding valve on it and see what happens. I'll try a second batch with the same yeast this weekend.

View attachment 693728

I'd venture to guess this is teh source of alot of homebrew stalling.I think the stall is most likely due to the temperature drop. That yeast likes to be warm, and most yeasts don’t react well to cooling after fermentation begins. Heat it up to 80 or even 90 to get it to finish faster. See Wyeast recommendations here:

https://wyeastlab.com/yeast-strain/belgian-saison

I'd venture to guess this is teh source of alot of homebrew stalling.

I'll try a second batch with the same yeast this weekend.

I think it was Escarpment labs that determined absence of simple sugar+presence of O2 caused diastatic enzyme production in this yeastI find it interesting that higher temperature, agitation, and open fermentation all work to decrease the solubility of CO2 in the fermenting beer. Many site one of these factors as either preventing or ending the stall. Depending on the Fast Ferment test process, it could also work to decrease solubility.

Yeast sensitivity to CO2 toxicity could be the factor

I further wonder if perhaps 2nd generation usage yields yeast less sensitive to CO2

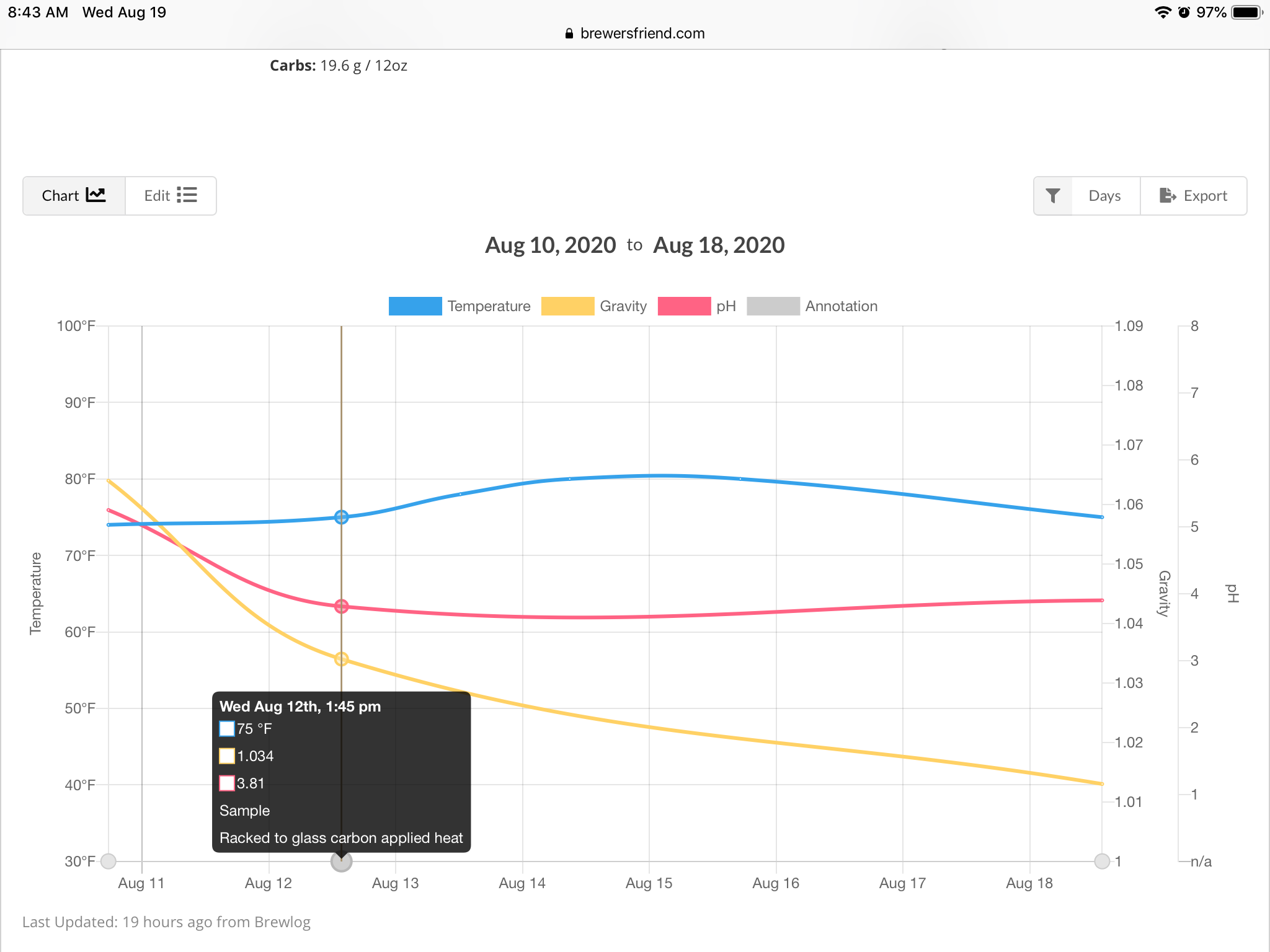

I just brewed 10 gallons last week open fermentation, they are at day 8 1.012. I did rack to glass carboys on day 2 when they were at 1.034

Nice, thanks for the data. A couple of questions: Was the yeast 3724? How much yeast did you pitch?

Life got in the way of kegging this weekend, but my saison is still chugging away. The tilt reading on the attached plot is slightly high, as my FG hydrometer read 1.006 when I took a sample. Tastes great though. I’ll likely keg this weekend and start carbing it up.