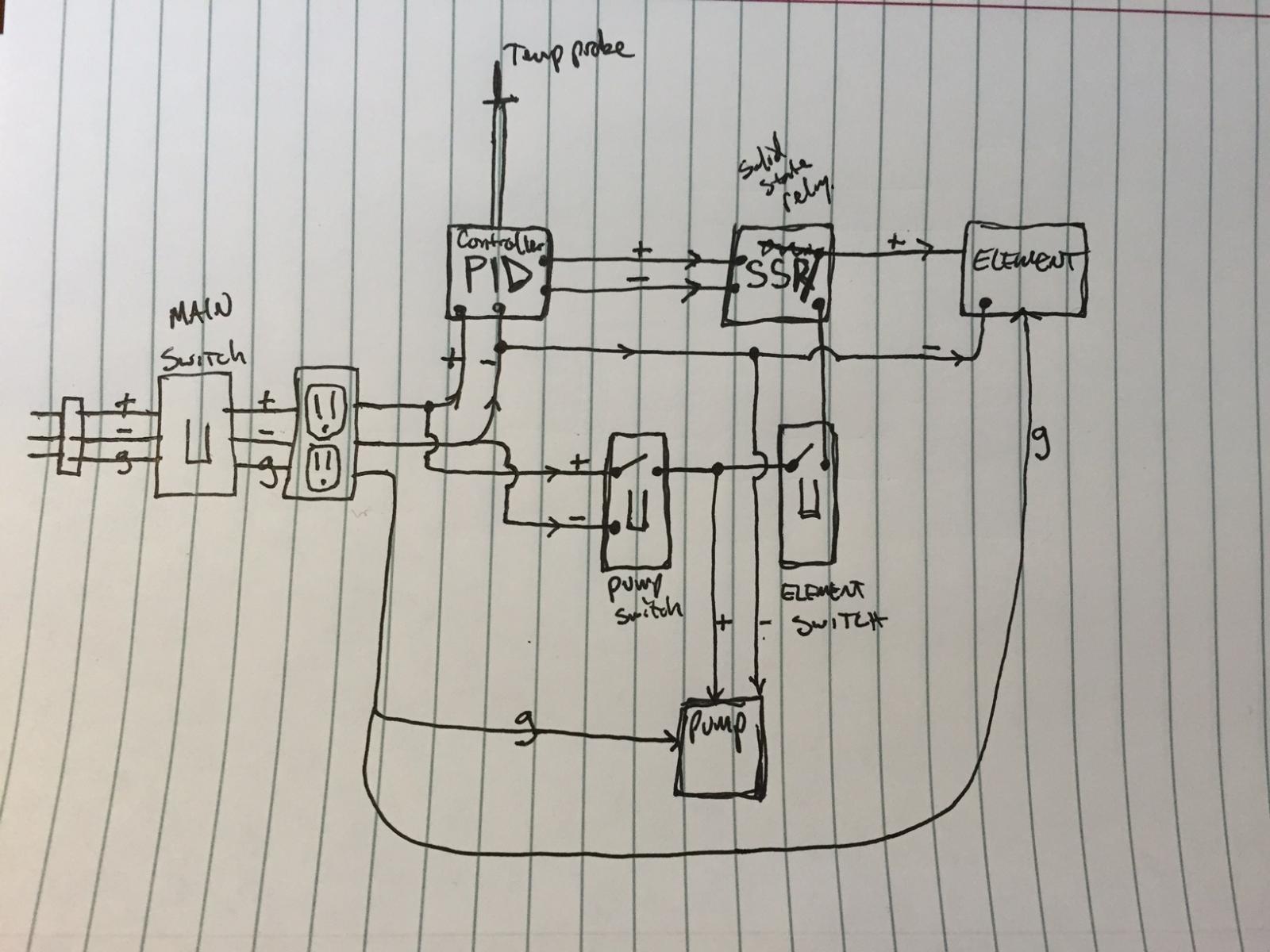

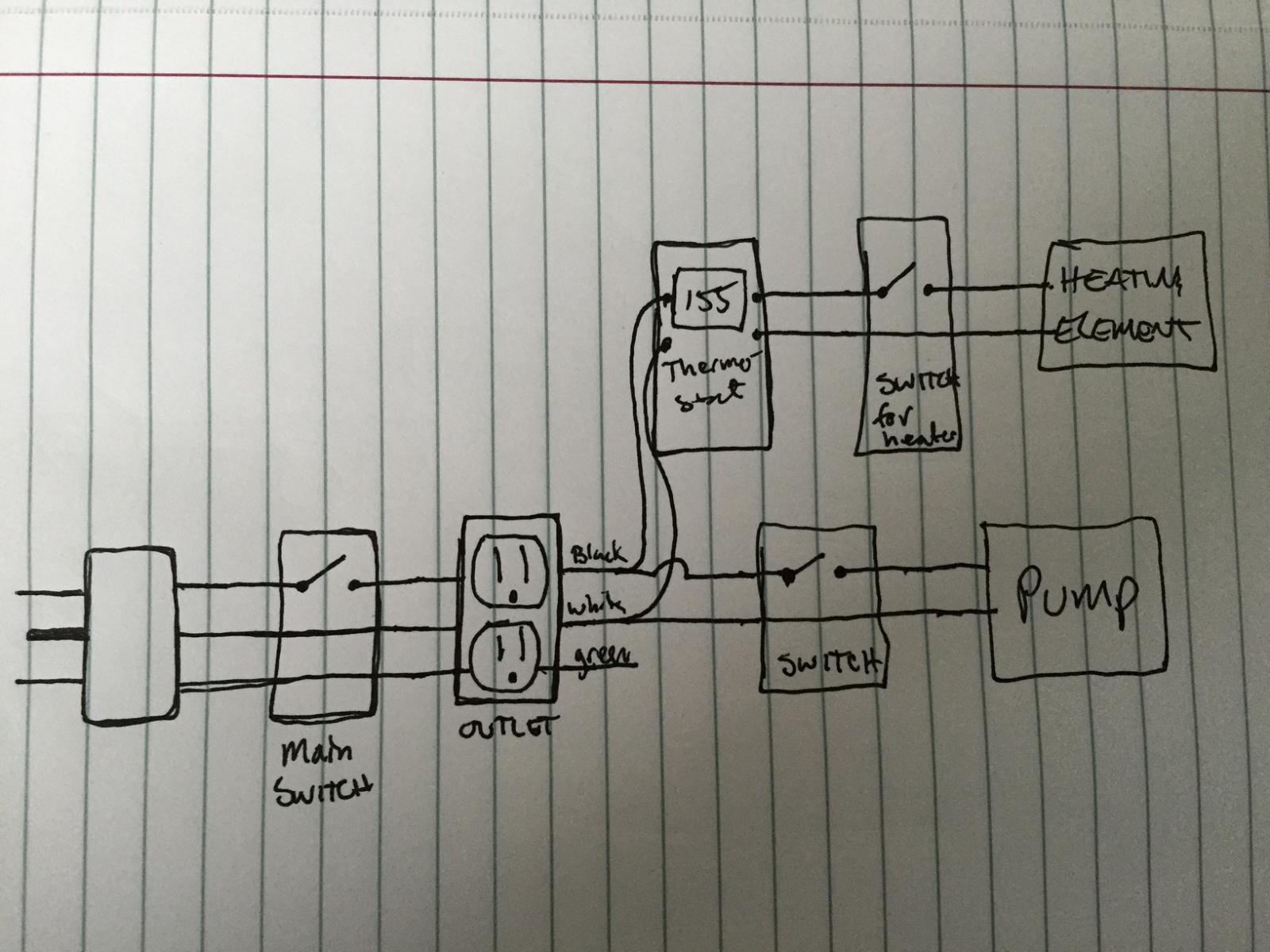

Okay, so I'm not an electrician and really not familiar with different types of relays, switches, etc. I can wire most stuff at my house but the current problem I have ran into building my simple RIMS system has me at a loss so I'm searching for some guidance. I'll attach a photo of a really dumbed down schematics version of what I currently have going. I'm basically trying to wire an outlet, a johnson controller thermostat and a pump. I would like to be able to turn the pump on and off independently, controlled by its own switch. I also want to have constant power to the Johnson controller so it is always monitoring temp. I am thinking of having a switch between the controller and the heating element so I can just leave it off when only running the pump. My problem is finding a way to switch off the heating element if the pump is turned off. Some kind of feedback or something. Its obviously not that hard to just switch the heat off when you switch the pump off but after a beer or two I might miss that. I was also planning on using one of those red switch that lights up so I dont miss it quite as easily.

So, is there anyway to create some kind of trip or fault or feedback (all some electrical terms I have heard, no doubt using them in wrong context) that will kill the power to the heater if the pump is turned off while allowing power to always be on to the Johnson controller?

Thanks a ton!

B

So, is there anyway to create some kind of trip or fault or feedback (all some electrical terms I have heard, no doubt using them in wrong context) that will kill the power to the heater if the pump is turned off while allowing power to always be on to the Johnson controller?

Thanks a ton!

B

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)