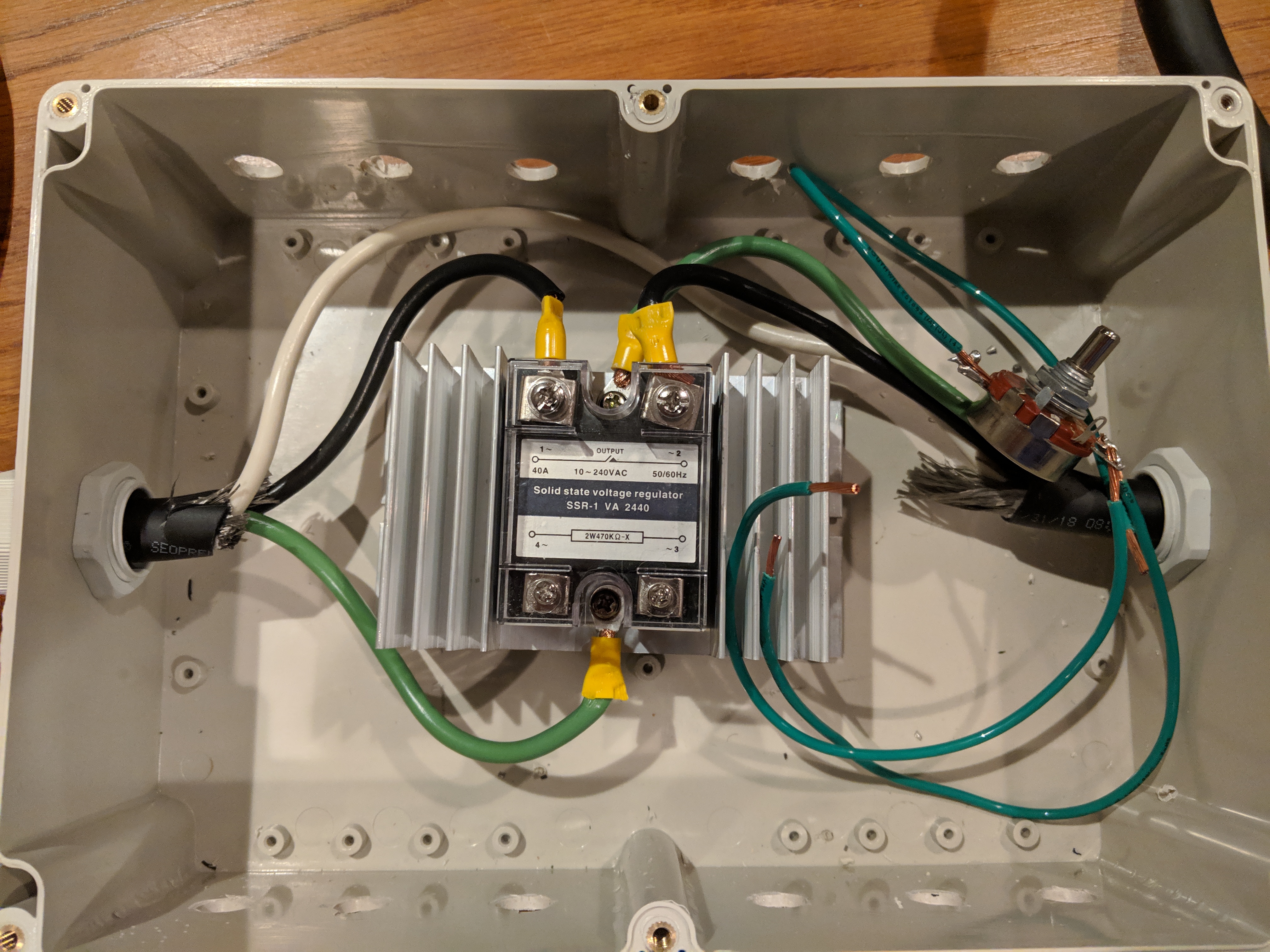

First time today I used the entire system--boil kettle with 5500 watt element, RIMS system for the mash tun. It's amazing how fast a 5500-watt element can heat water.

And the beauty of the RIMS approach is I was able to hit my mash temp.

On top of that, I used the steamslayer system to avoid all that boil steam going into the garage. It worked shockingly well.

+1 for electric.

And the beauty of the RIMS approach is I was able to hit my mash temp.

On top of that, I used the steamslayer system to avoid all that boil steam going into the garage. It worked shockingly well.

+1 for electric.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)