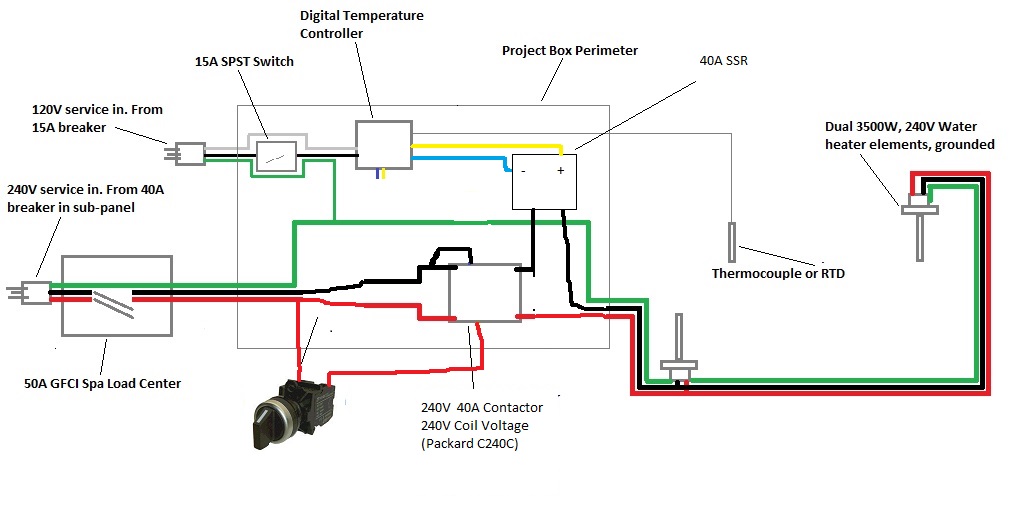

Regardless of what you use, i wouldn't ever recommend using a contactor in place of a SSR. They should be used for two distinct different purposes. SSR's for directly controlling power into your elements as they can cycle quickly, and contactors hooked up to switches to be toggled on and off by hand to control where power is even allowed to go.

With how slow a STC1000 responds i personally wouldnt use it to control even a HLT, the fastest you can have it cycle is once a minute and depending on what volumes your working with and your ambient temp you can easily drop a few degree's in 1 minute of the HLT water recirculating.

This also allows you to get away from using a more expensive 40A(not even sure where you buy these?) switch. You never want your active high current actually flowing through your switches, thats how you get electrocuted. You use the switches to control your Contactor's coil pins which use a very very small amount of current which in turn allow your main hot voltages through.

I would do something like this...Overall it adds only like $20 to your existing build, although it might end up being the same cost since i have no idea how expensive a 40A switch is. One 2 selector toggle switch to control the contactor coils to allow the 240V in. I am unsure what the yellow and blue wires were, i assume your SSR control output + and -, so i wired those to the SSR control pins. In reality on the 2 selector toggle its not coming in the left and out the right, the switch has two NC sides. You wire it up the input and output of one NC side(say the right) so when your switch is off(To the left) there are no wires even plugged in so no power gets to your coil but when you turn the switch to the right it opens and allows the hot(red) voltage through to your coil, completing the required 240V circuit with the black hot wire and activating the contactor allowing the red and black hot voltages through to your SSR which is then cycled on and off by your controller via its input pins. Hopefully that makes sense

Oh and i'd buy two and use the same 2 position selector switch for your 120V input as well.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)