IndyBlueprints

Well-Known Member

Hey Guys,

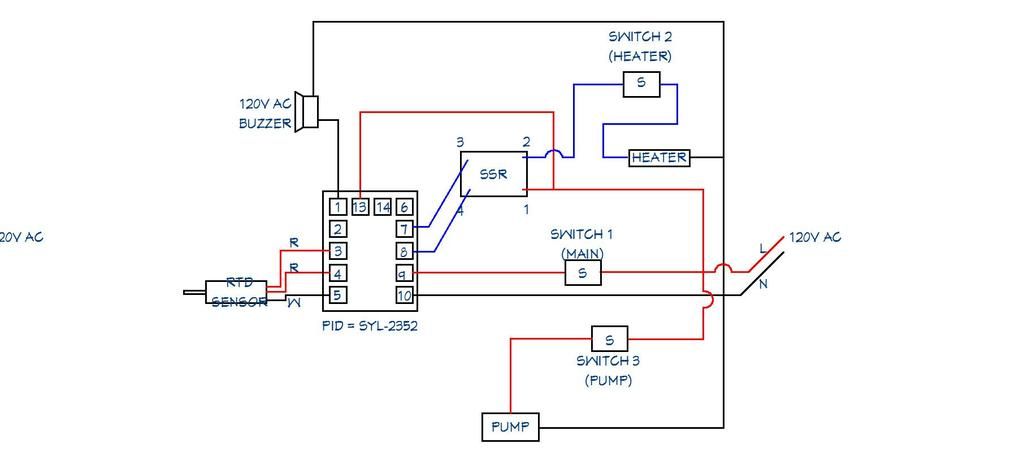

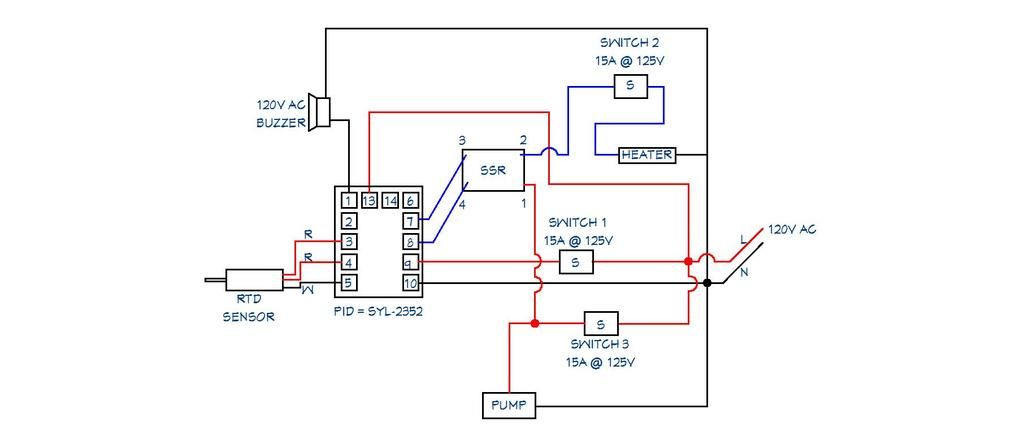

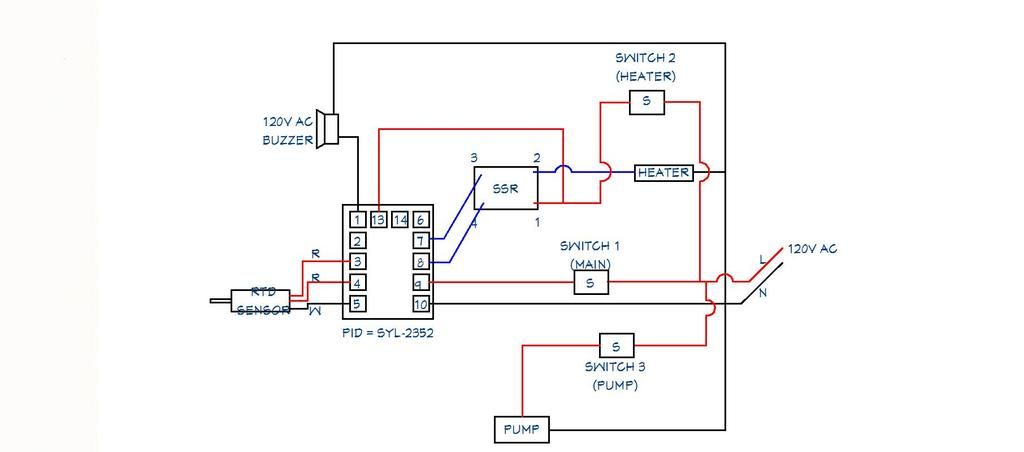

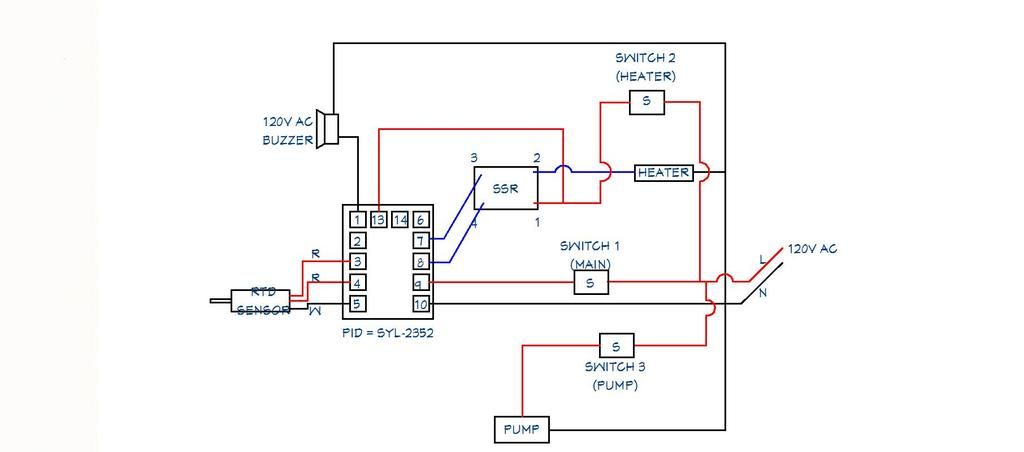

I am a rookie with wiring diagrams, so I need a little direction. I have a single PID (SYL-2352) running a RIMS tube. What I'm trying to set up is a box with 3 switches. The first switch will turn the whole system on. The second switch will allow the SSR to bring power to the heating element. The third switch will allow me to manually switch on the circulating pump.

I have a 5,000W 240V heating element running on 120V, so effectively 1,375W @ 120V.

My switches are Radio Shack DPDT Heavy Duty Toggle Switches rated at 10A @ 125V AC.

My first question is, are these switches strong enough for the job?

My second question is, Does my wiring diagram look right?

I am a rookie with wiring diagrams, so I need a little direction. I have a single PID (SYL-2352) running a RIMS tube. What I'm trying to set up is a box with 3 switches. The first switch will turn the whole system on. The second switch will allow the SSR to bring power to the heating element. The third switch will allow me to manually switch on the circulating pump.

I have a 5,000W 240V heating element running on 120V, so effectively 1,375W @ 120V.

My switches are Radio Shack DPDT Heavy Duty Toggle Switches rated at 10A @ 125V AC.

My first question is, are these switches strong enough for the job?

My second question is, Does my wiring diagram look right?

Last edited: