- Joined

- Dec 19, 2013

- Messages

- 314

- Reaction score

- 380

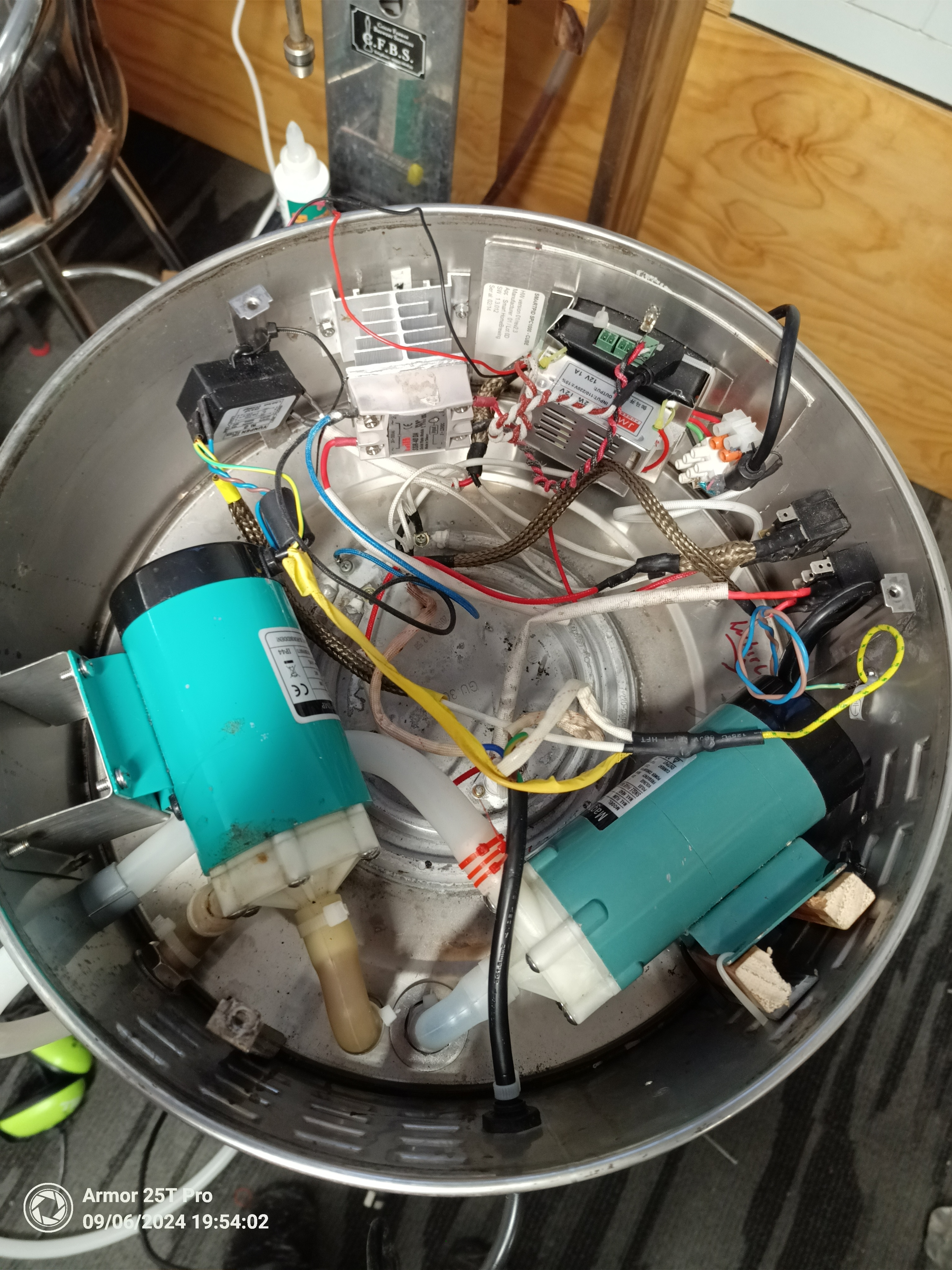

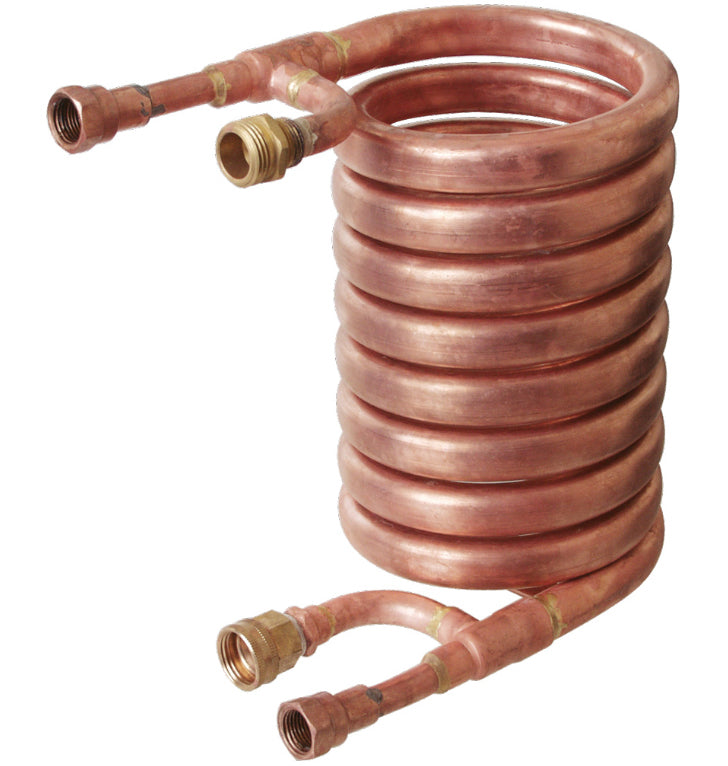

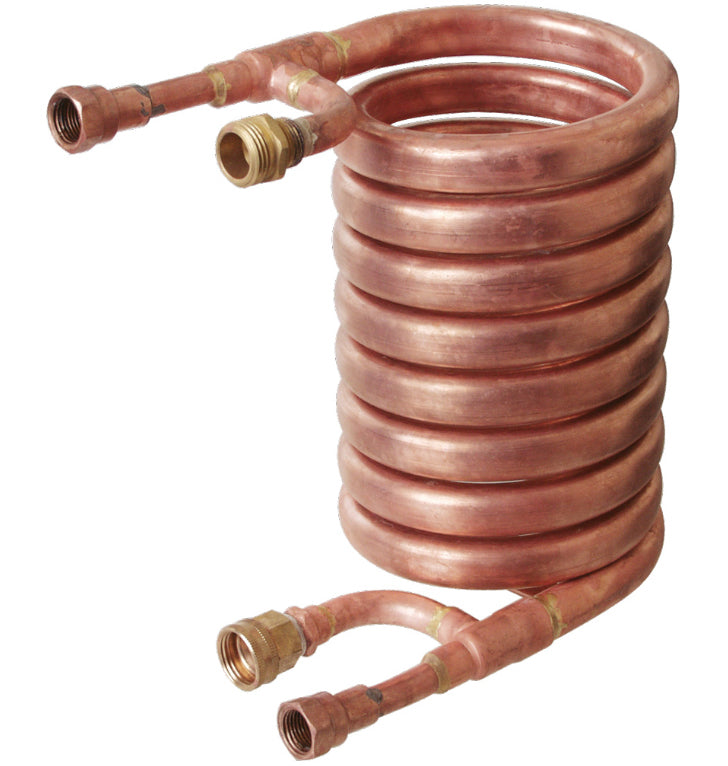

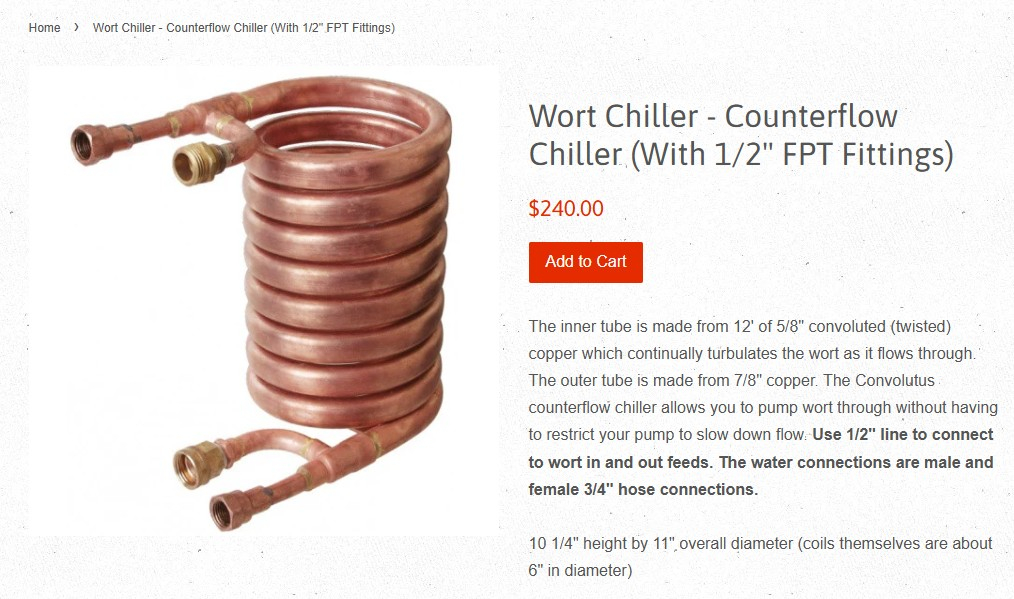

Hi all. I’ve been looking to upgrade from my DIY counter flow to something better. I was about to pull the trigger on an Exchillerator after deciding that’s what I want. But I was in my LHBS yesterday and he had what seemed to be a used all copper chiller. It was tagged at $200 but he told me he’d cut me a deal since it been there awhile. I don’t know what brand these are under or who makes them but know they a like $300ish new. I’ve seen a lot of them in photos on here. Picture below. I’m assuming the Exchillarator is better since they are both copper on the inside where it counts, but the Ex has the inner band to make the water twirl. But it s $240-$290 depending on the config. Just curious if anyone has used both? Or even anyone who has used the copper one and can say how good it is? Seems like there are no reviews of this no name chiller that shows up in a lot of photos. Thanks.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)