BrooklynTrout

Member

Hi All,

I'm new to the hobby and still trying to make a decent flavored cheese. I just took my third farmhouse cheddar out of the press.

The first cheese I made didn't set a clean break, but I was able to get curds anyway. It had a lot of moisture and produced a ton of brown and green mold under the wax, so it got tossed. It tasted sour and acidic.

The second cheese looked beautiful, but also took extra time to curdle. I wanted to taste it with only a little aging to make sure I was doing things correctly before moving on. It only aged a month in a cold refrigerator. While it had a nice, slightly crumbly texture, it also tasted bland with an acidic, spoiled milk aftertaste. It sort of tasted like really cheap cheese. This cheese also had required some extra time to set up.

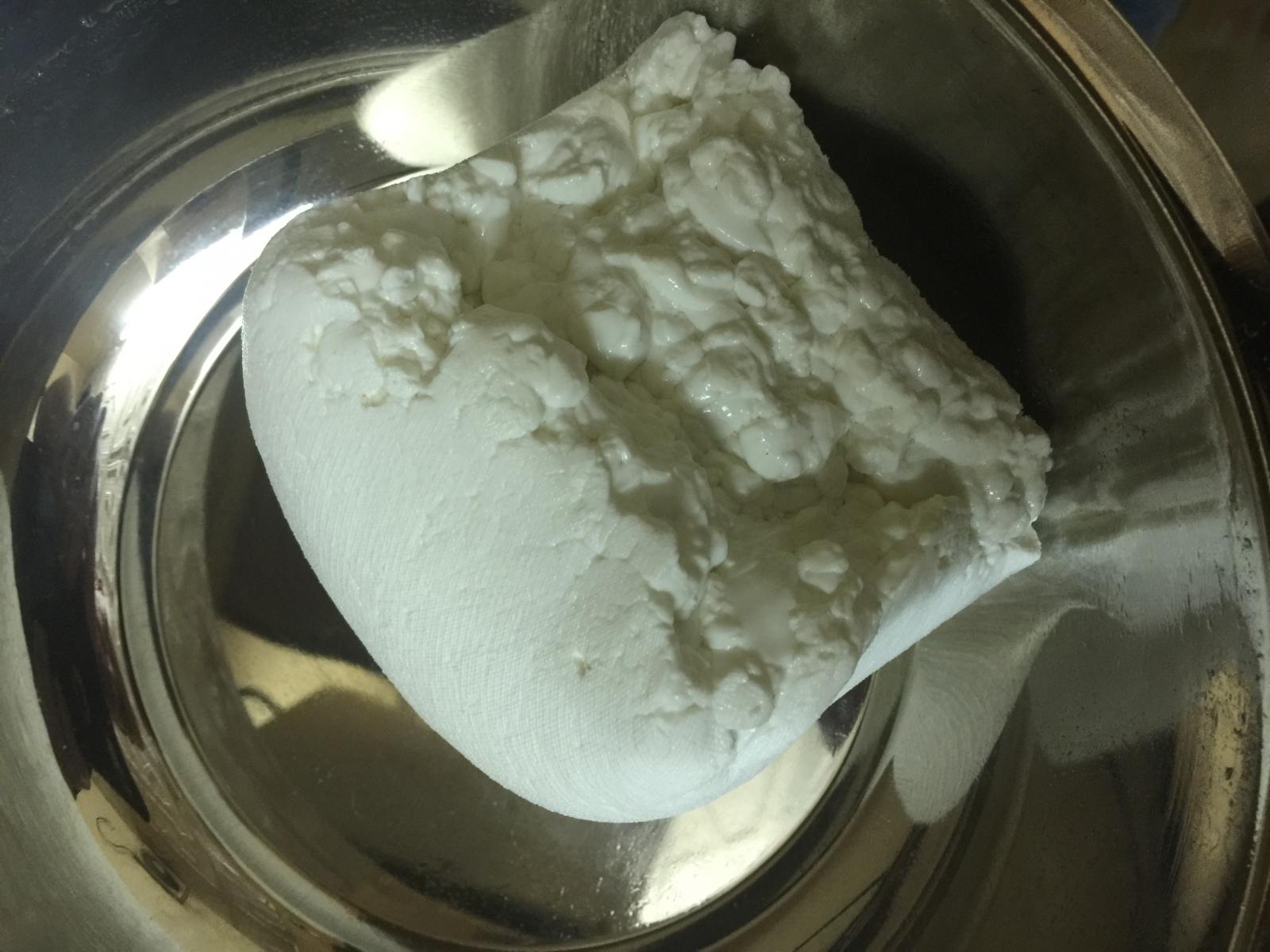

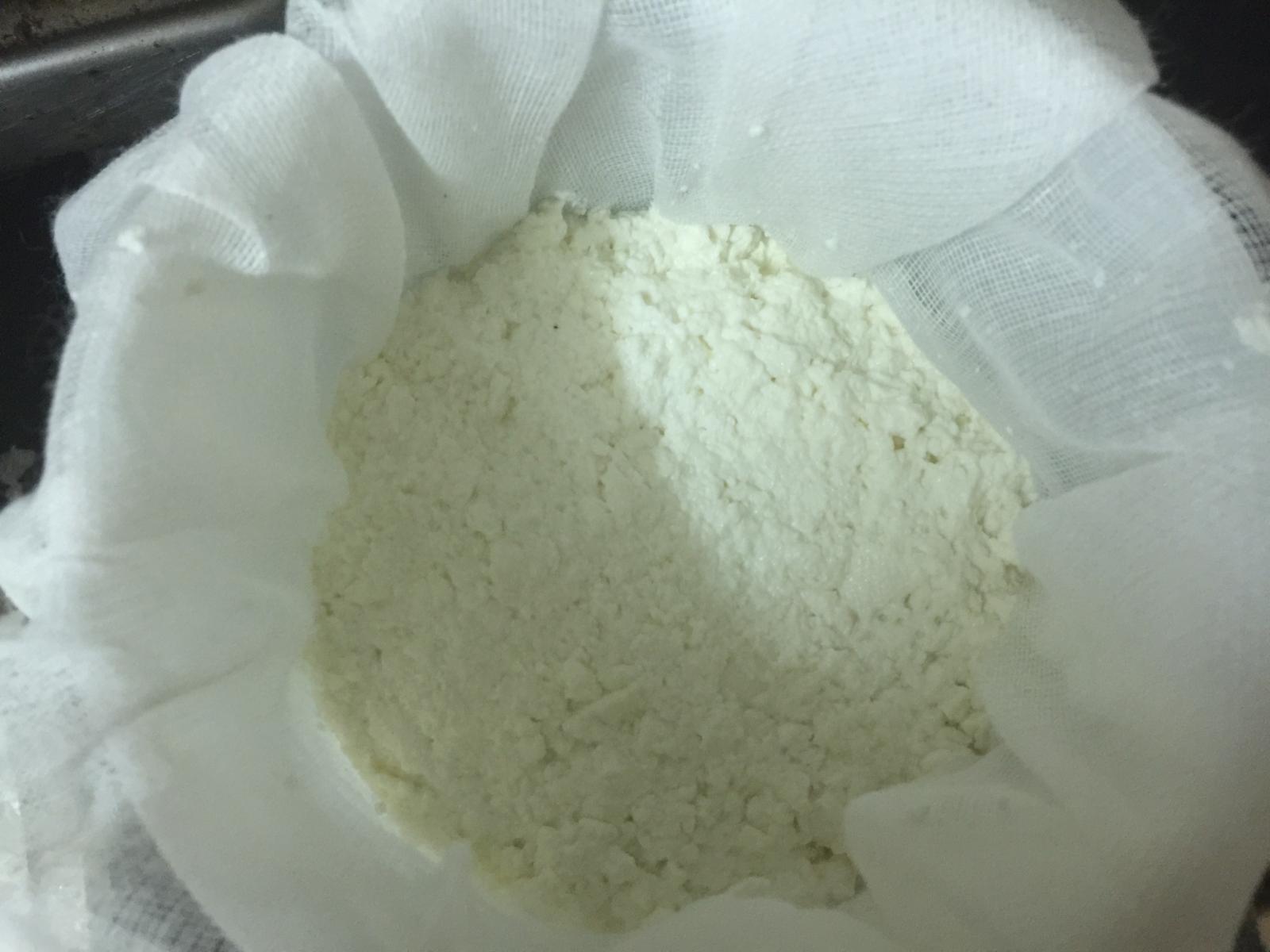

For the third attempt, I tried to eliminate all possible causes of bad taste. I boiled everything in the entire kitchen. I purchased some really expensive slow pasteurized, non-homogenized milk. I used a double-boiler. I followed the instructions to the T. Even still, the milk took an extra 15 minutes to set. I got a bit of whey at the bottom of the bowl while milling and adding salt. I'm not sure if that is normal. The curds tasted bland, but not sour, so I was hopeful.

I pressed and now the cheese is drying. I cut a piece off to sample before waxing and ONCE AGAIN (dangit!) there is a sour after taste. So my question is why? Here are my ideas:

- The taste is normal and the cheese just needs to age

- Despite my cleanliness, I'm getting other bacteria in there.

- There is excess acid developing because the milk takes a long time to set

- I'm not cooking the curds until they are hard enough, trapping too much moisture

- Something else?

What should fresh, un-aged cheddar taste like anyways?

I'm really appreciative of any advice. I plan on making farmhouse cheddar again and again until it tastes good or my wife locks me up.

Sean

I'm new to the hobby and still trying to make a decent flavored cheese. I just took my third farmhouse cheddar out of the press.

The first cheese I made didn't set a clean break, but I was able to get curds anyway. It had a lot of moisture and produced a ton of brown and green mold under the wax, so it got tossed. It tasted sour and acidic.

The second cheese looked beautiful, but also took extra time to curdle. I wanted to taste it with only a little aging to make sure I was doing things correctly before moving on. It only aged a month in a cold refrigerator. While it had a nice, slightly crumbly texture, it also tasted bland with an acidic, spoiled milk aftertaste. It sort of tasted like really cheap cheese. This cheese also had required some extra time to set up.

For the third attempt, I tried to eliminate all possible causes of bad taste. I boiled everything in the entire kitchen. I purchased some really expensive slow pasteurized, non-homogenized milk. I used a double-boiler. I followed the instructions to the T. Even still, the milk took an extra 15 minutes to set. I got a bit of whey at the bottom of the bowl while milling and adding salt. I'm not sure if that is normal. The curds tasted bland, but not sour, so I was hopeful.

I pressed and now the cheese is drying. I cut a piece off to sample before waxing and ONCE AGAIN (dangit!) there is a sour after taste. So my question is why? Here are my ideas:

- The taste is normal and the cheese just needs to age

- Despite my cleanliness, I'm getting other bacteria in there.

- There is excess acid developing because the milk takes a long time to set

- I'm not cooking the curds until they are hard enough, trapping too much moisture

- Something else?

What should fresh, un-aged cheddar taste like anyways?

I'm really appreciative of any advice. I plan on making farmhouse cheddar again and again until it tastes good or my wife locks me up.

Sean

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)