Yeah it’s a great idea. You opened up all sorts of possibilities with the Nor Cal products for canning jars. You could even dump the exhaust if you you got creative eliminating the oxygen into the wort altogether.No problem, I really like this because of being able to have more control of dumping the trub and harvesting yeast and not disturbing to much in the fermenter, the lid that came from nor-cal and the 1 1/2" tri-clamp and the 3/4" ball valve were all sources individually but pretty easy to put together

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What kind of fermentor are you using..

- Thread starter Jcpomp

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

VirginiaHops1

Well-Known Member

I'm using corny kegs. I take a hit on my batch size but I can ferment two at the same time in my temp controlled chest freezer.

I started fermenting in cornies recently and I'll never look back. I do small 2.5-3 gallon batch so maybe I'd feel differently if I did larger batches, but it's fantastic for me. Easy to clean, easy to do closed transfers, easy to cold crash with no O2 pickup, still fits in my chest freezer ferm chamber. I can add dry hops while blasting gas into the post to create counter pressure, similar to how a lot of commercial breweries add dry hops. I can easily purge my serving kegs during fermentation by just hooking them up with jumpers. I brew mainly IPAs and lately NEIPAs so I'm pretty anal about oxidation.

Looks cool. Any pictures of the build? Did you start with a copper pot?

I ferment in 5 gallon cornys. Relatively inexpensive, pressure regulated and set up by default to pressure transfer. Fit nicely in my keezer set at 40 degrees. Ferment with controllable heat wrap at whatever temp I want and simply turn it off to cold crash. Add 5# co2 and send it to the serving keg. So simple it’s a bit silly.

Constructed with brazed together sheet. Truth be told, I didn't build it. 12 years ago I got it from a guy that did. I do have his construction DIY that I'm guessing he wouldn't mind if I shared. Only thing I did was add a top, Brewcoat lining and stand.Looks cool. Any pictures of the build? Did you start with a copper pot?

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.98

DYKWSWYX Heavy Duty Brewing Gloves (1 Pair) - 55CM Long Chemical Resistant Plastic Gloves for Beer & Wine Making, Cleaning, Homebrew Equipment Protection

wuhanshijiayangzhiyimaoyiyouxiangongsi

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

Slightly off topic.

To the folks here that regularly use big mouth bubblers, do any of you use seedling mats as a heat wrap? I started using one recently for my glass jugs, but I'm making a bigger batch and wanna use my bmb. From the manufacturer, it says to not wrap plastic containers, but I've also regularly seen these things ignored. They don't seem to throw out that much heat to me, and it would ideally not be on for very long each time it kicks on. Any others have luck? Or am I asking to melt my fermenter and burn my house down...

To the folks here that regularly use big mouth bubblers, do any of you use seedling mats as a heat wrap? I started using one recently for my glass jugs, but I'm making a bigger batch and wanna use my bmb. From the manufacturer, it says to not wrap plastic containers, but I've also regularly seen these things ignored. They don't seem to throw out that much heat to me, and it would ideally not be on for very long each time it kicks on. Any others have luck? Or am I asking to melt my fermenter and burn my house down...

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

Another easy option if your fermenting in a freezer or fridge is a lightbulb in a paint can. It works well and is only a few dollars. CheersSlightly off topic.

To the folks here that regularly use big mouth bubblers, do any of you use seedling mats as a heat wrap? I started using one recently for my glass jugs, but I'm making a bigger batch and wanna use my bmb. From the manufacturer, it says to not wrap plastic containers, but I've also regularly seen these things ignored. They don't seem to throw out that much heat to me, and it would ideally not be on for very long each time it kicks on. Any others have luck? Or am I asking to melt my fermenter and burn my house down...

Mer-man

Well-Known Member

I spund in my serving kegs. So a corny with a red cask widge is stupid easy for racking off the yeast, using CO2 to push it, and leaving yeast cake to harvest/repitch.

Also cheap and very easy to clean.

Also cheap and very easy to clean.

I have 8 of those and love them.

bracconiere

Jolly Alcoholic - In Remembrance 2023

I have 8 of those and love them.

You wouldn't know a good replacement for the o-ring, would you? mine got old and cracked....

I think that works good, the gasket can be kinda a bear to get inplace but not too bad. one thing that i really didn't like was the butterfly valve, it was fairly aggressive no matter what i did, so I eliminated it, I got a mason jar lid with an 1 1/2" tri clamp that I installed and added a 3/4" ball valve so that when I want to drain the trub and whatever else I have a ball valve and can dump slowly and not introduce a jar of oxygen to the fermenter through the beer. Overall I really like it, easy to clean, easy to use, and I like that it is clear, I'm one of those people that likes to see the fermentation process

I have a catalyst and really like it. Your mod to get rid of the butterfly valve is a great idea. Do you bottle or keg? The clear bottling attachment is very convenient because it fits my bottling wand tubing. The larger diameter barbed fitting on the ball valve Is good to dump trub. Is there a reducer to fit the smaller tubing of the bottling wand, or can you swap out for a smaller sized barb fitting while still on the fermentor? Any other ideas? Thanks for sharing your great idea.

Thank you, I both bottle and keg, I have a 3/8" barb fitting for kegging and a 1/4" for the smaller bottling wand, thats the great part of a standard size ball valve like mine, its super easy to get fittings for just about anything that you would think of. like I said the catalyst is a great product but my first mod to it was the lid, i really hated how the center of the lid convexes down almost into the fermenter, my issue with this is that the high krausen would contact this lid and find its only way out of a pressurized vessel, the airlock. The top of the lid has a shoulder on it that is about 1 1/2" wide so I drilled a couple 3/8" holes in it and added airlock gaskets to those spots so I can have two airlocks, now they can bubble away without getting plugged up, and the center one i plug with a solid bung.

You wouldn't know a good replacement for the o-ring, would you? mine got old and cracked....

I don’t, I’m guessing you could find silicone cord or use a silicone caulk.

I saw a person or two mention fermonsters. I've read that the plastic is quite thing, Is this a major issue? I worry that the thin plastic around the spigot would be extra leaky? I've gone back and forth on getting a 3G for myself, but I ignored the reviews on the bmb universal lid and kind of regret that (still works fine, the duct tape gives it some charisma..). But I don't wanna do the thing same twice.

bracconiere

Jolly Alcoholic - In Remembrance 2023

I don’t, I’m guessing you could find silicone cord or use a silicone caulk.

thanks for the suggestion...But i'm already out $24 trying to find something, and the feed store sells the complete brand new bucket for $20 new....(homebrewer cheap syndrome again!, lol)

mirthfuldragon

Well-Known Member

I saw a person or two mention fermonsters. I've read that the plastic is quite thing, Is this a major issue? I worry that the thin plastic around the spigot would be extra leaky?

I have three of the 7g ones and I like them. No leaks. The triangular (ish) spigot o-ring goes on the inside with the flat part against the plastic wall. There is also a trick to installing the lid gaskets, so watch a youtube video on how to do it correctly - I screwed it up the first time.

lorne17

Well-Known Member

- Joined

- Jan 14, 2013

- Messages

- 360

- Reaction score

- 30

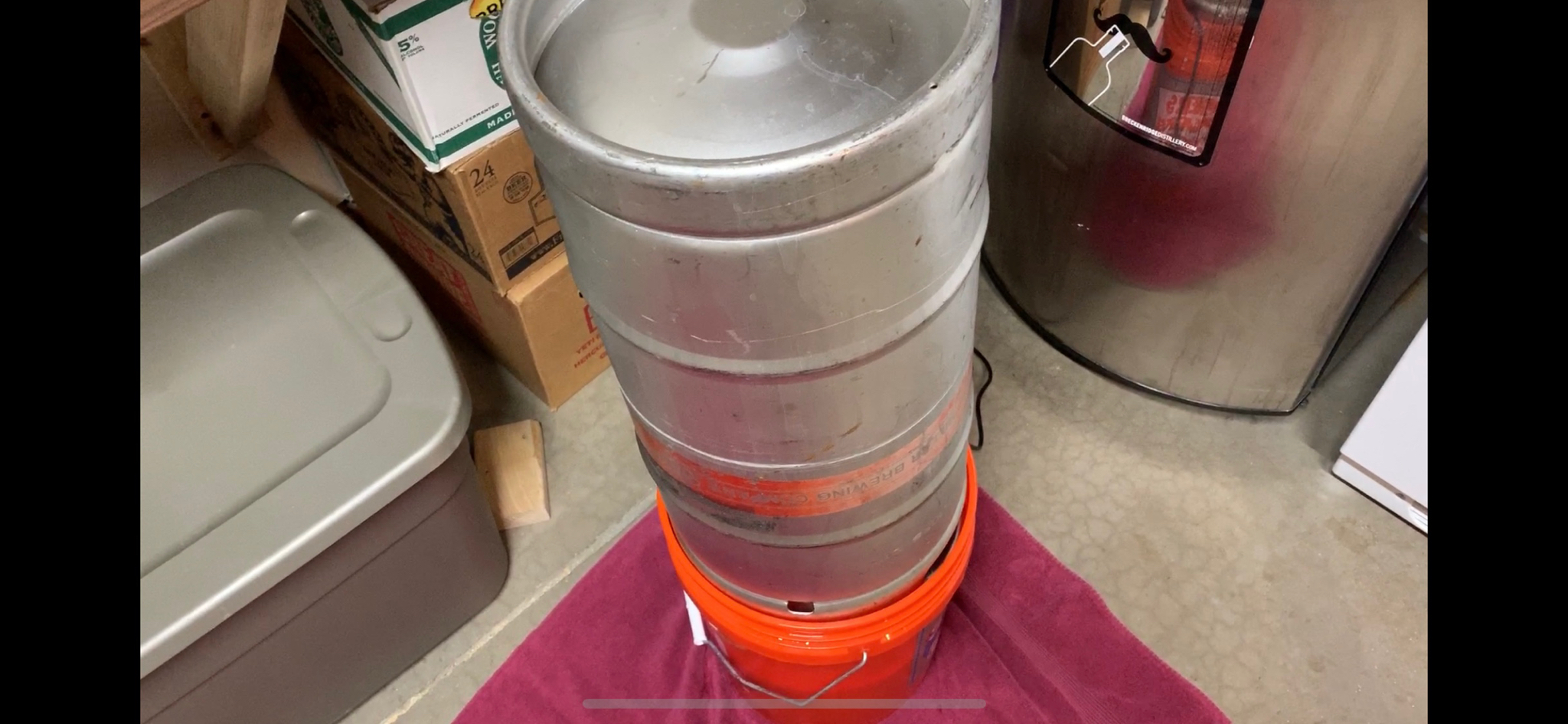

I actually use a closed fermentation system. I ferment under low pressure in a 1/4 barrel (7.75 gal) keg with a spunding valve. I love it because the beer doesn’t see oxygen until it hits my pint glass from the serving keg. I can transfer kegs really easy by using CO2 and pushing from the fermenting primary keg to a clean secondary keg with dry hops or flavoring.

It’s improved my beer for sure! I actually sold my FastFerment because it was collecting dust.

Let me know your thoughts or if you use a spunding valve!

It’s improved my beer for sure! I actually sold my FastFerment because it was collecting dust.

Let me know your thoughts or if you use a spunding valve!

mirthfuldragon

Well-Known Member

Out of curiosity, how much of a hassle is it in practice to deal with commercial keg spears and cleaning, at the homebrew level?I actually use a closed fermentation system. I ferment under low pressure in a 1/4 barrel (7.75 gal) keg with a spunding valve.

lorne17

Well-Known Member

- Joined

- Jan 14, 2013

- Messages

- 360

- Reaction score

- 30

It's actually not that bad. Once you get the hang of using two small flat head screwdrivers, it's pretty quick and easy to take the ring out that holds the spear in (sorry I don't know the formal names). Then I usually soak it in PBW for a bit and rinse it out. Haven't had any problems. I use a brush in the spear to get everything out.Out of curiosity, how much of a hassle is it in practice to deal with commercial keg spears and cleaning, at the homebrew level?

Putting it back to gather is actually easier, just a pair of pliers to pinch the ring back in place.

Little effort to ensure no oxygen will hit my beer!

Hope this help,

Lorne

lorne17

Well-Known Member

- Joined

- Jan 14, 2013

- Messages

- 360

- Reaction score

- 30

It's actually not that bad. Once you get the hang of using two small flat head screwdrivers, it's pretty quick and easy to take the ring out that holds the spear in (sorry I don't know the formal names). Then I usually soak it in PBW for a bit and rinse it out. Haven't had any problems. I use a brush in the spear to get everything out.

Putting it back to gather is actually easier, just a pair of pliers to pinch the ring back in place.

Little effort to ensure no oxygen will hit my beer!

Hope this help,

Lorne

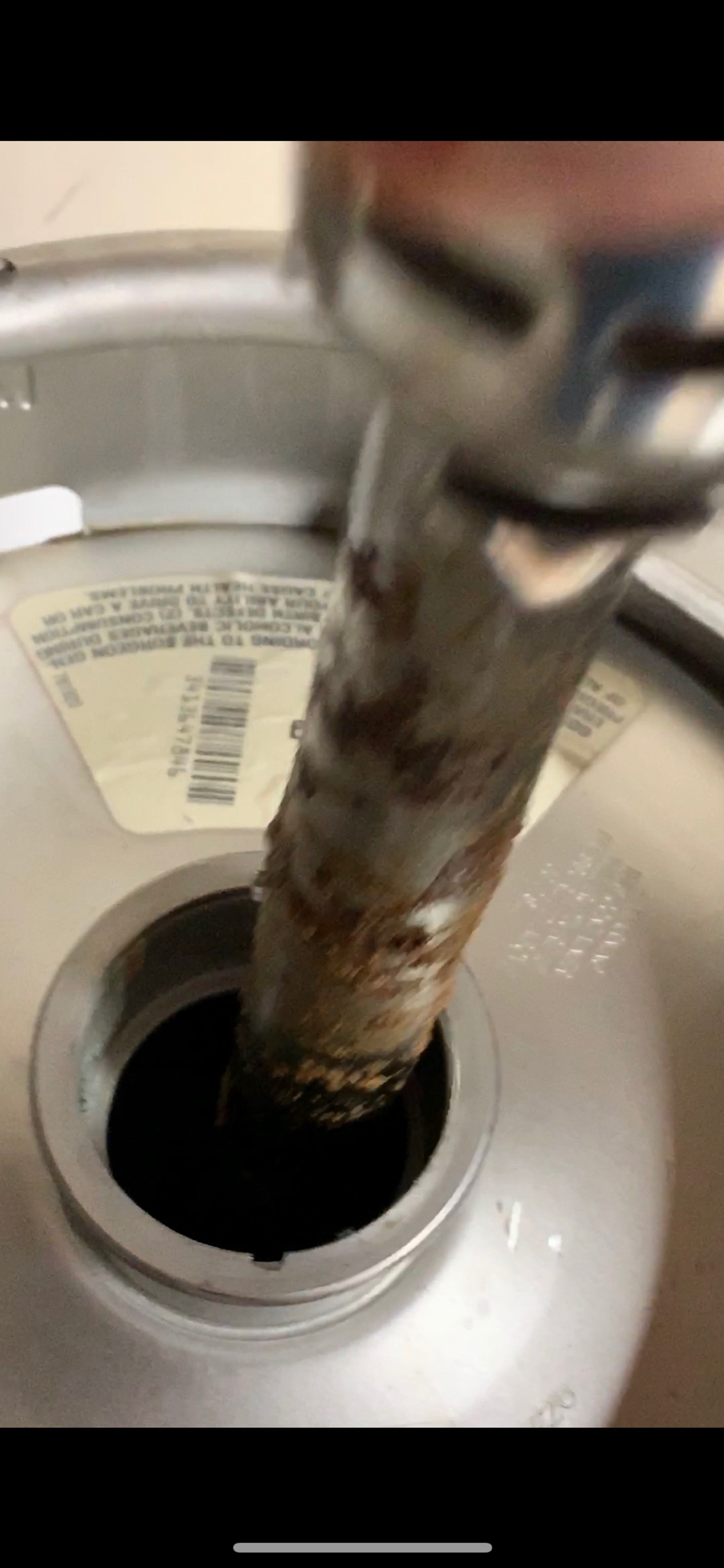

So I needed to clean my fermentation keg and just walked through the steps.

1. Remove all CO2 in keg before removing spear and ring.

2. Use two small flat head screw drivers to pry ring out. Once it’s started it’s easy. I searched YouTube for it.

3. Remove spear and rinse all trub out.

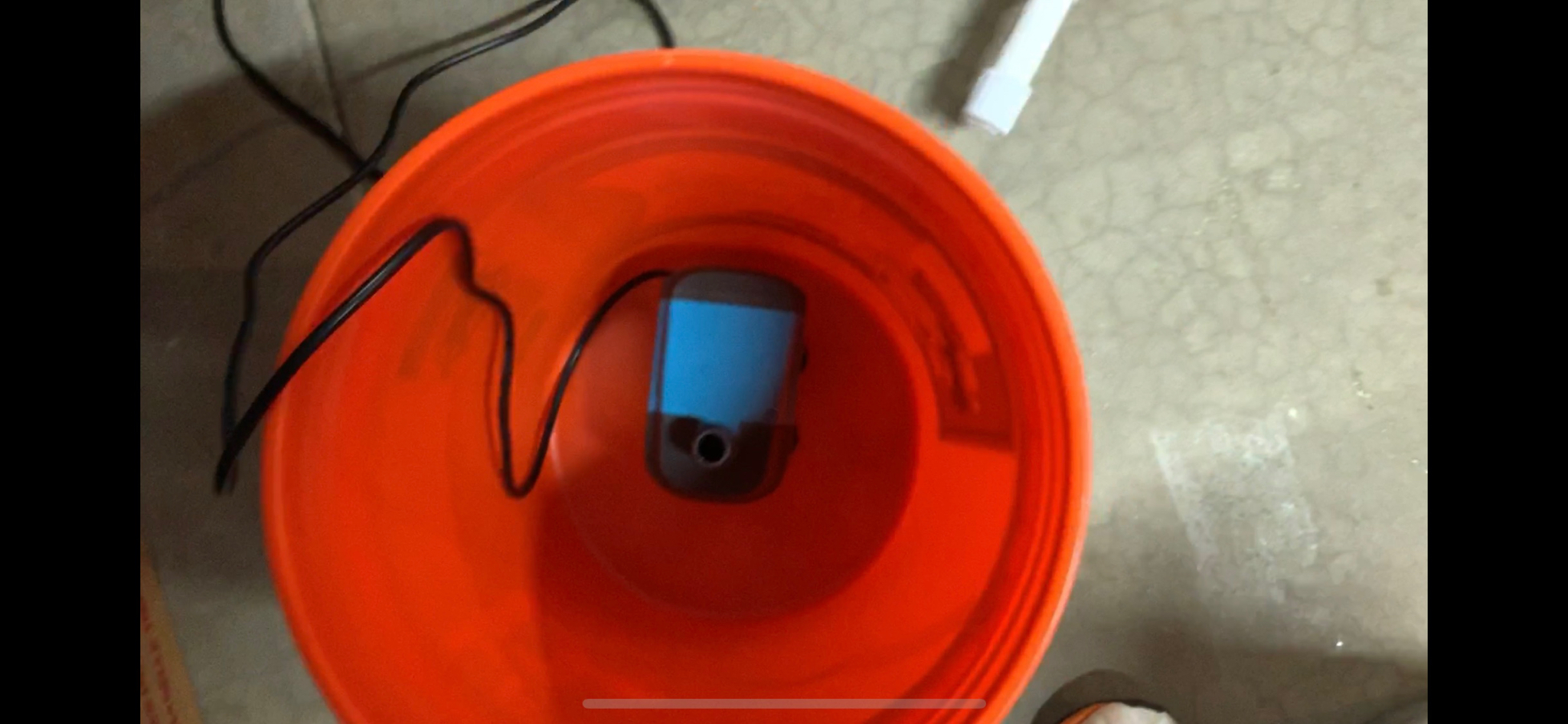

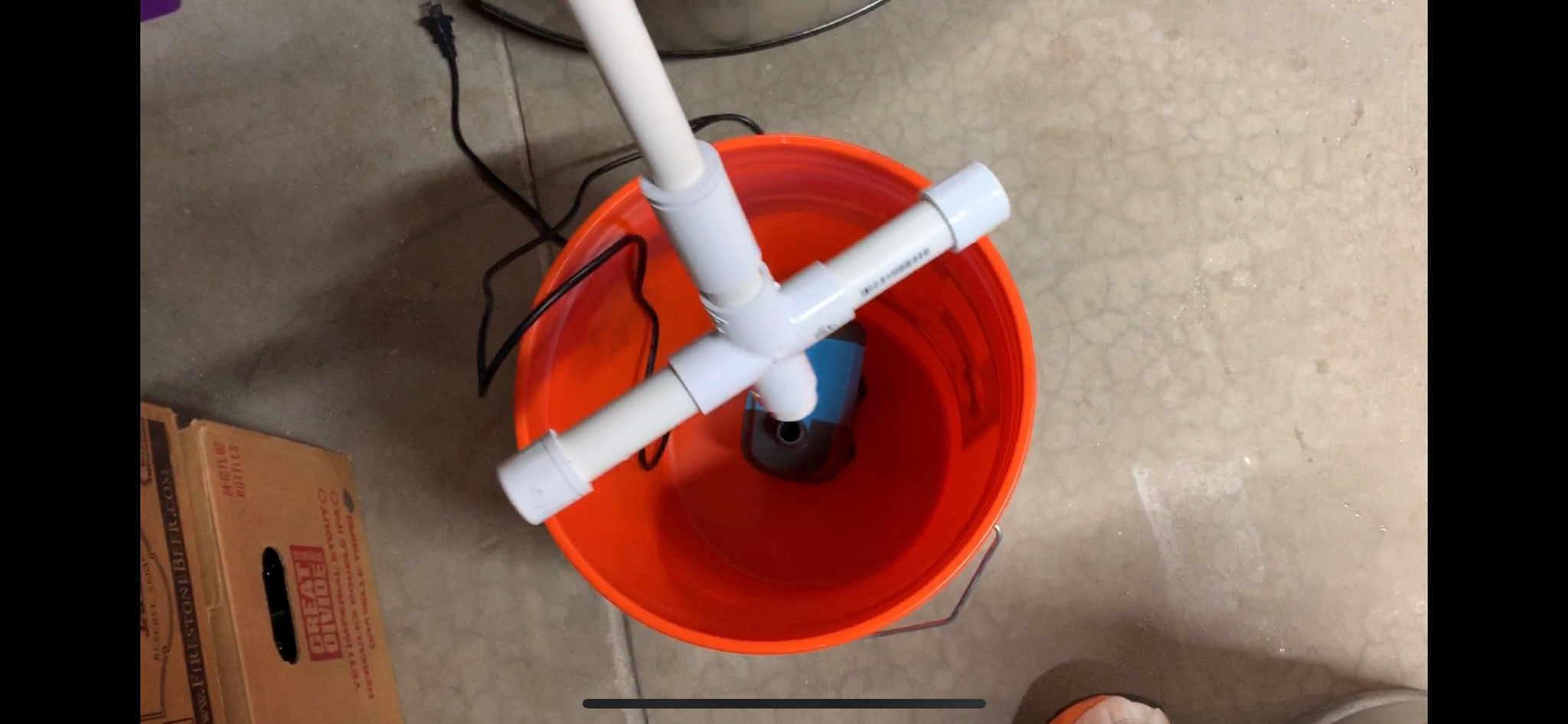

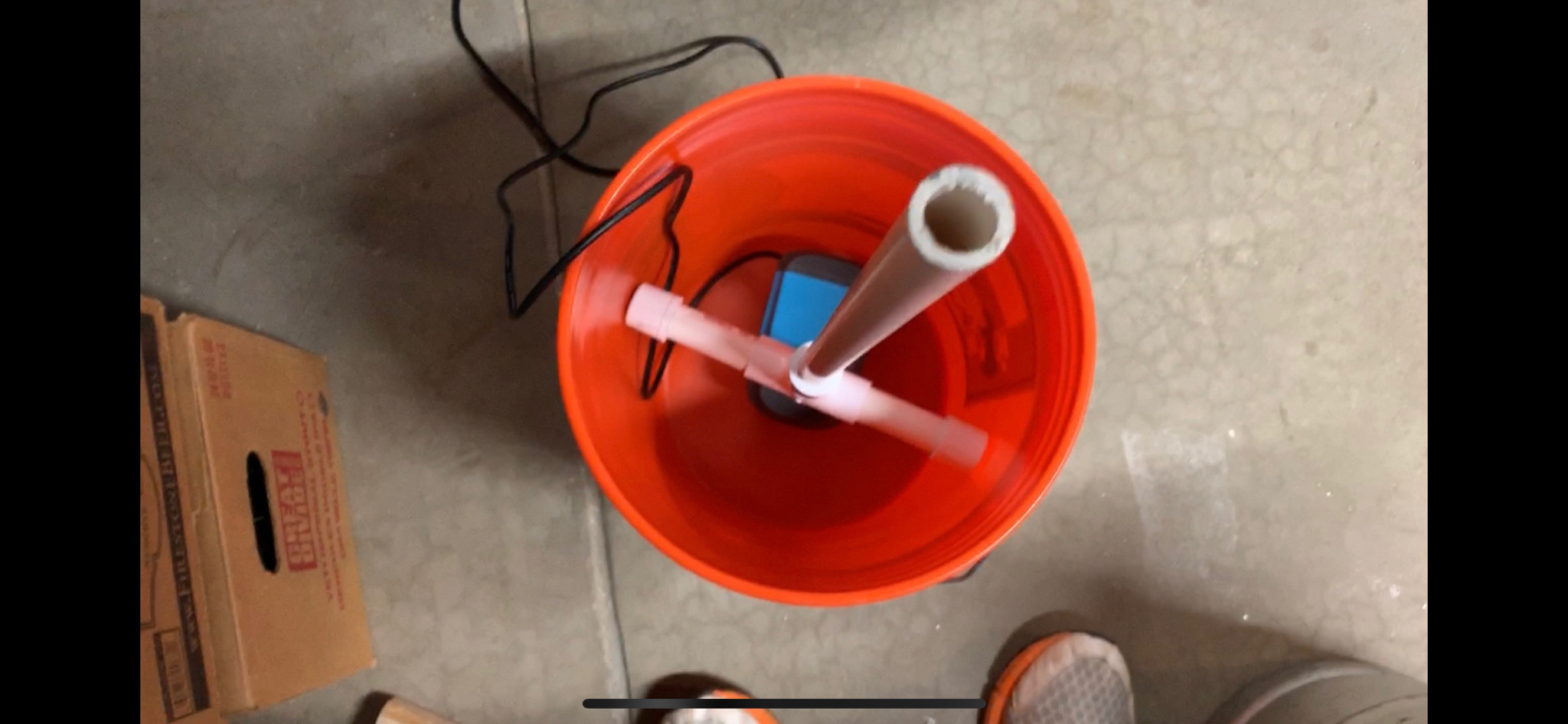

4. I then have a 5 gallon bucket from Home Depot and a high pressure water pump from Horrible Freight. I got some PVC pipes and found a tutorial online to make a T to easily clean out my keg and or car boys (if i used mine anymore).

5. I use no perfume oxi-clean and super hot water. Submerge the pump

In the bucket and then a bit extra.

6. Flip keg over on top of the PVC sticking up and turn pump on (don’t do this before your keg is on or you’ll have water everywhere).

7. Let it run for 20 mins or so.

8. Then do the same for water to rinse clean.

9. You’re done just sanitize it before you ferment in it again!

Hope this helped! I tried to do a video but it was a failure so I wrote it out.

Hope this helps,

Lorne

mirthfuldragon

Well-Known Member

Hope this helped! I tried to do a video but it was a failure so I wrote it out.

Thank you very much for the write-up. I was wondering about how it was in a practical sense - I have watched videos and seen how it is done, and it seems simple enough, so I was more interested in how it works as a practical matter, such as whether it was something you got annoyed doing or whatnot. Seems like it is simple enough, so I will have to keep my eye out for some quarter barrel kegs. Thank you again!

lorne17

Well-Known Member

- Joined

- Jan 14, 2013

- Messages

- 360

- Reaction score

- 30

Thank you very much for the write-up. I was wondering about how it was in a practical sense - I have watched videos and seen how it is done, and it seems simple enough, so I was more interested in how it works as a practical matter, such as whether it was something you got annoyed doing or whatnot. Seems like it is simple enough, so I will have to keep my eye out for some quarter barrel kegs. Thank you again!

It’s not super simple by any means. But once you do it a few times you get the hang of it. Overall worth it since my beer is much better with this spunding process.

Also 1/4 barrel kegs are hard to come by. It took months before one showed up on CraigsList. I had a notification set so it would tell me when one came up. It was months of weeding through alerts just on kegs for sale or kegerators. Then finally a 1/4 barrel showed up and I pounced!

I actually had a half barrel for the time being and it’s just so dang cumbersome to clean and handle.

Hope that helps,

Lorne

They aren't as common to find used in the normal homebrew channels, but they're far from hard to come by. You can buy them new from stout tanks and elsewhere. The market for new and used sankes is very healthy with craft brewers buying and selling constantly.Also 1/4 barrel kegs are hard to come by. It took months before one showed up on CraigsList. I had a notification set so it would tell me when one came up. It was months of weeding through alerts just on kegs for sale or kegerators. Then finally a 1/4 barrel showed up and I pounced!

lorne17

Well-Known Member

- Joined

- Jan 14, 2013

- Messages

- 360

- Reaction score

- 30

They aren't as common to find used in the normal homebrew channels, but they're far from hard to come by. You can buy them new from stout tanks and elsewhere. The market for new and used sankes is very healthy with craft brewers buying and selling constantly.

Good to know thanks! I know it was hard to find in Colorado!

Buying new is always possible at around $120 from what I found.

Always stainless for primary and secondary. Easy to clean and sanitize. Durable unless I do something stupid.

thanks for the suggestion...But i'm already out $24 trying to find something, and the feed store sells the complete brand new bucket for $20 new....(homebrewer cheap syndrome again!, lol)

I do have a few that are cracked, if I find the source I’ll keep you in mind.

Good to know thanks! I know it was hard to find in Colorado!

Buying new is always possible at around $120 from what I found.

$120 with shipping for buying one from stout. In Colorado, I’d be surprised if you couldn’t get new slim quarters for $90 and sixtels for $75 or less.

For example:

https://www.probrewer.com/classified-ad/ambrach-kegs-new-pricing/

bracconiere

Jolly Alcoholic - In Remembrance 2023

I do have a few that are cracked, if I find the source I’ll keep you in mind.

Thanks! i'll do the same, just seems like a waste to have to buy a whole new bucket for what probably is a 50 cent foam gasket...

Zooksta

Well-Known Member

Budz

Member

- Joined

- Mar 22, 2019

- Messages

- 5

- Reaction score

- 7

I'm still using a 20 year old More Beer 12.5 gallon conical that I recently had customized. I found someone nearby that doesn't charge much for sanitary welding of stainless. I replaced the racking arm and had a TC flange welded to the bottom to eliminate all threaded fittings, and I had 3 TC flanges welded to the lid for a blowoff fitting, a thermowell, and a sight glass/window (it came with a single small hole drilled in the lid). I keep it in a homemade insulated fermentation chamber powered by a dorm room frig with the door removed, and a computer fan in the chamber to keep the cold air circulating. The only thing I don't like is that 20 years later, More Beer is still using the same garbage lid gaskets that keep coming apart.

Do you cut the serving post above trub level?I ferment in 5 gallon cornys. Relatively inexpensive, pressure regulated and set up by default to pressure transfer. Fit nicely in my keezer set at 40 degrees. Ferment with controllable heat wrap at whatever temp I want and simply turn it off to cold crash. Add 5# co2 and send it to the serving keg. So simple it’s a bit silly.

Usually to 1/2 inch.Do you cut the serving post above trub level?

Similar threads

- Replies

- 2

- Views

- 381

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)