Could you recommend a good guide for how to do this? "

This my process:

Close transfer instructions

1. Fill the keg with no foam sanitizer by using a bottling bucket with a spigot. Run the hose from the spigot to the out post using a black disconnect. Ensure the keg is tilted so the gas disconnect is the highest point. Attach a spare gas QD. Open the spigot until sanitizer comes out the gas QD. The keg is now full of sanitizer.

2. Use the same hose you filled the keg with but close the spigot, detach it from the bottling bucket spigot, and place the lose end in the bottling bucket. Attach 2-3 psi from a CO2 tank to the gas in post. Once CO2 begins to bubble in the now full bucket of sanitizer disconnect the black QD. Disconnect the gas in QD from the keg.

3. Turn the keg upside down by turning it towards the gas in post with the gas in post at the lowest point (slightly tilted). Using a spare gas in grey QD, install the QD to allow residual sanitizer to escape. (Shortened gas in dip tube helps with getting all the residual out) Do not allow all the CO2 to escape.

4. Using the same hose you used to fill and drain the keg, attach the black QD onto the liquid out post and while gas is escaping quickly attach it to the spigot of your fermenter. Tighten hose clamp. You just purged the line with CO2.

5. Attach a hose to the spare grey QD and install it on the gas in post of your purged keg. As CO2 is escaping attach it to the top of your fermenter. You just purged the line with CO2 and created a pretty darn close oxygen free closed loop.

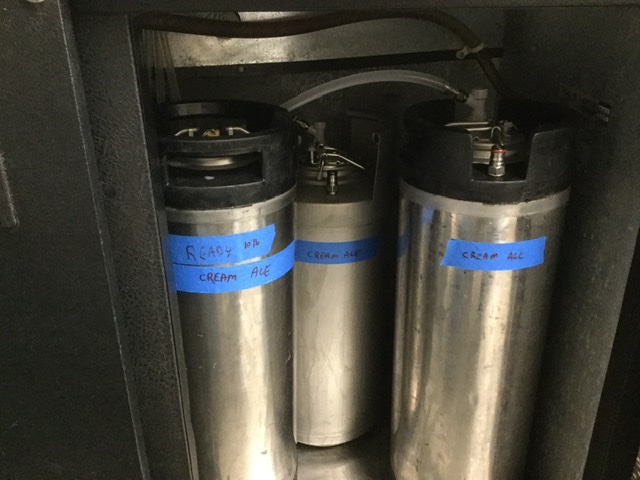

6. Open drain on the fermenter, have a beer. Wait until beer comes out the gas in line. I like to lay my keg on its side with the gas in post high for this. You now have a full keg of beer that displaced the CO2 in the keg by pushing it into the fermenter.

7. Once full, with keg upright and level, apply a small amount of pressure to the keg and a tap. Drain a bit of beer until you no longer hear CO2 bubbling in beer. You just created CO2 filled headspace.

Hope this helps.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)