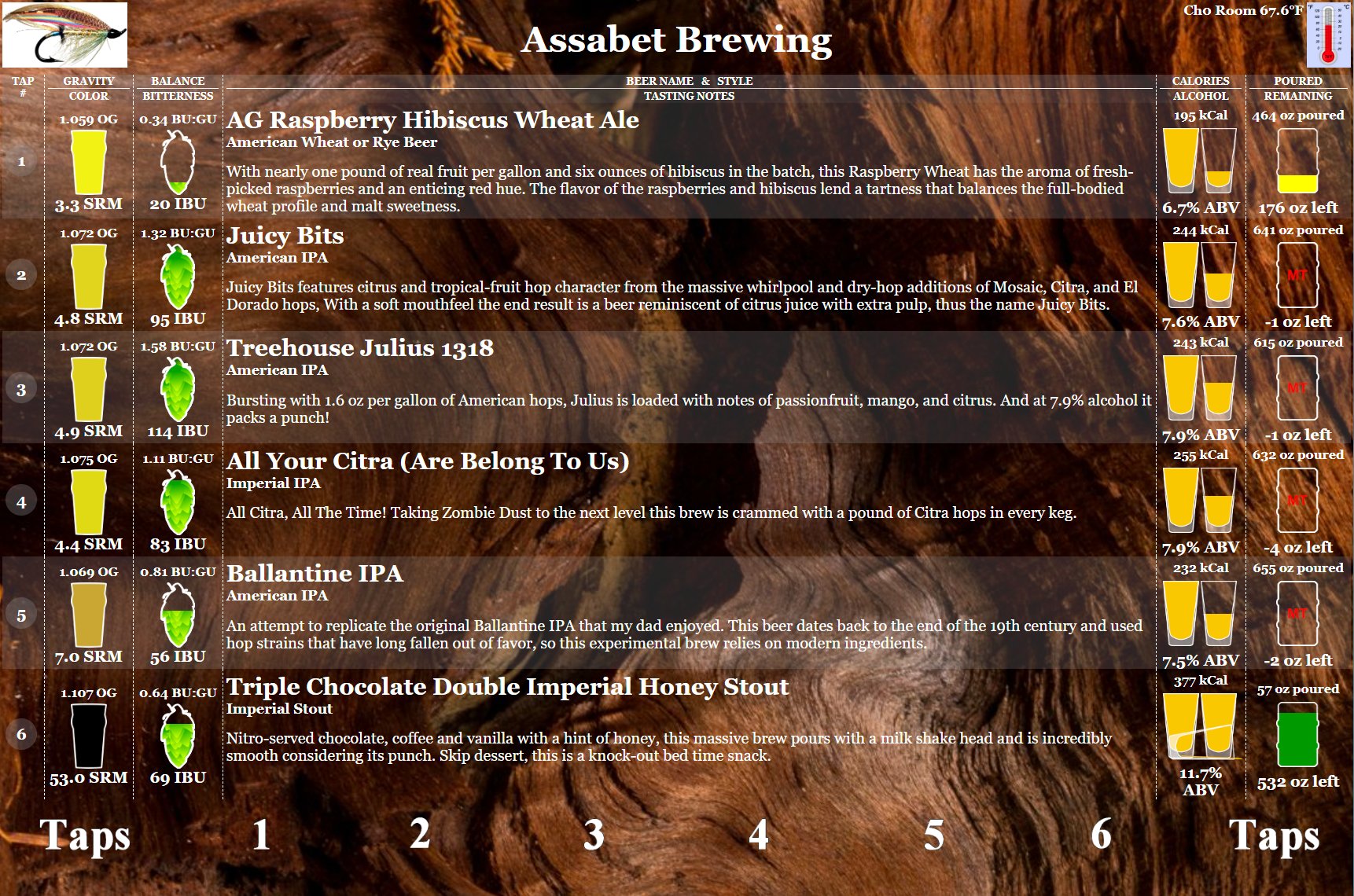

To make a very long story shorter, I had major surgery on my right leg 5 weeks ago and this morning my surgical team finally said I can start "doing stuff" as long as it didn't stress my leg. I had planned on the surgery and recovery and had brewed six 10 gallon batches of beers to get me through. Five of those kegs kicked over the last few days with the Ballantine IPA kicking last night...

The stout had kicked on Friday, and my youngest son came over to swap in its fresh mate. But I was on my own now for the rest. I decided to go all-in and take the opportunity to clean the keezer lines.

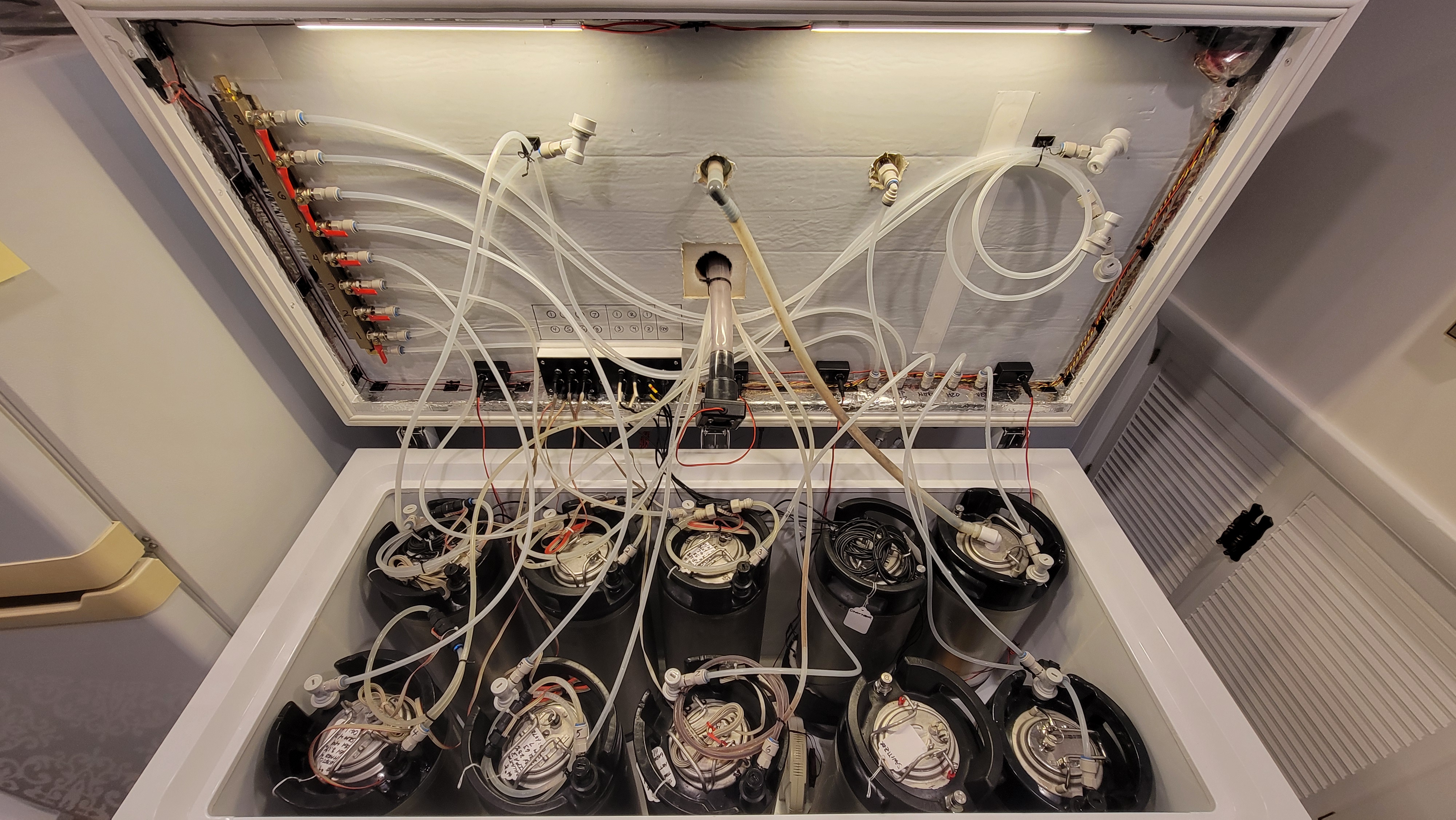

First, I pulled out the four kegs that needed replacing and hooked up the manifold to the six beer QDs.

Then I hooked the drain manifold to the faucets...

Pump on one bucket, drain lines in the other, to pre-rinse the lines...

And away we go!

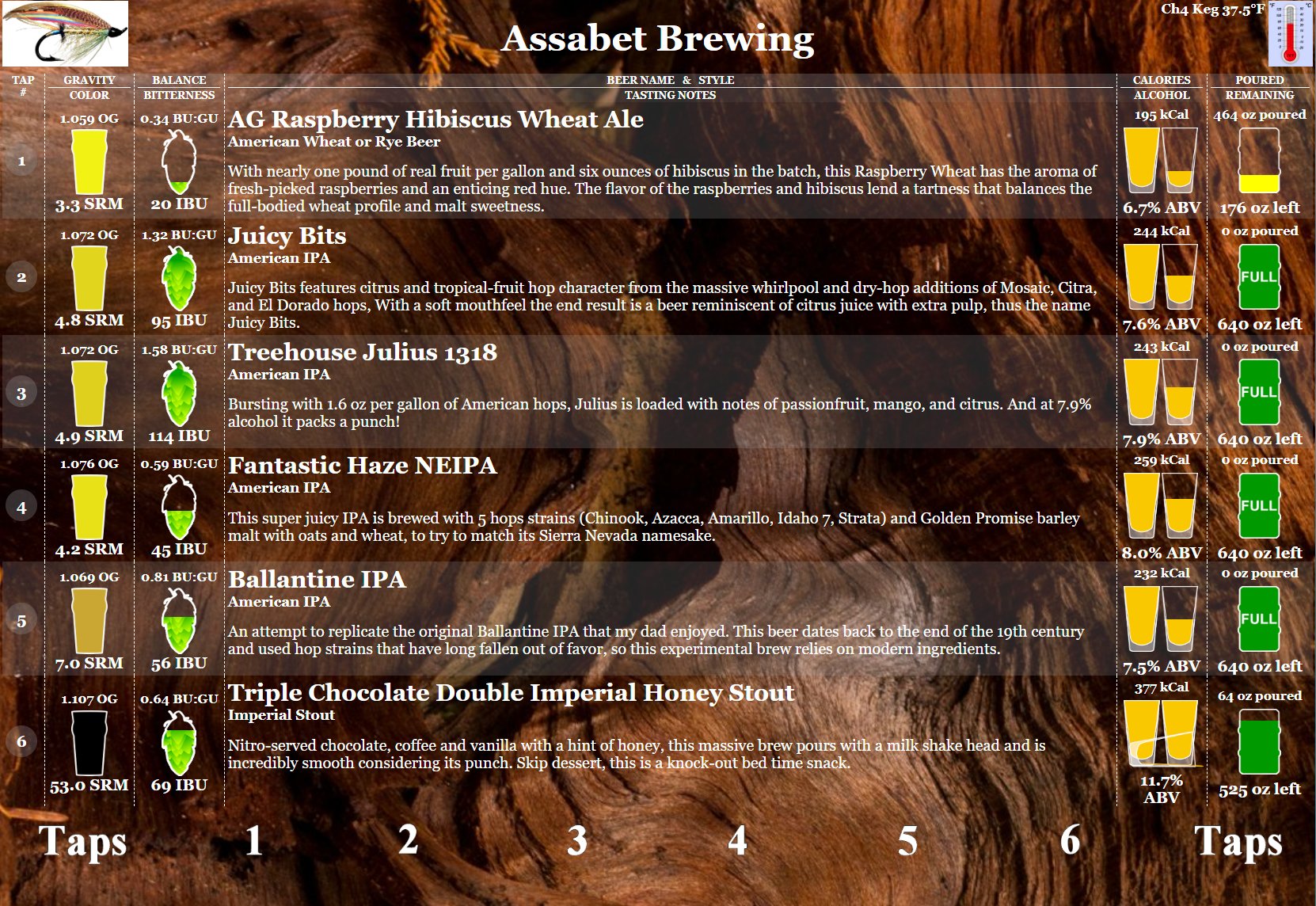

Rinsed out the cleaning gear and put it away, then loaded the keezer with four fresh kegs!

Taplist looks much better now

With that done I brought out the trusty Mark II and cleaned the five kicked kegs...

Leg is a bit throbby and I nearly filled the vacuum drain I still have connected to it, but it seems to have held up ok.

Totally worth it though!

Cheers!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)