It was an interesting day, with the following saga offered for your entertainment

Mixed up a fresh batch of Star San, cleaned a couple of kegs, and checked on the fermentations going on. In my wanderings I happened to notice a wet spot on the floor of my utility room which is directly off the brewery space. Said wet spot was under the well pump pressure switch, which sits atop a 1/4" brass NPT nipple screwed into the input to our 30 gallon pressure tank. Put just a whisper of pressure on the switch to see if the nipple would screw in any tighter when the whole thing sheared right the **** off, erupting in a geyser of water that caught me square in the face. Holy cow!

So I have my thumb over the hole and I've effectively stopped the gusher. I'm totally soaked head to slippers, and The Spousal Unit is out fetching groceries. I was able to reach the shutoff for the pump and flipped that off, and was also able to reach the bypass valves for each of the 50 gallon water treatment tanks (neutralizer and media filter), all without taking my thumb off the hole. Also was able to toss a coiled hose that I keep connected inside the utility room into the sink in the brew space just outside the utility room doorway, intending to use it to drain the system down until the pressure tank was completely relieved. Unfortunately the hose has a shutoff valve screwed on the far end and I couldn't reach that without letting go of the geyser for five seconds - which was about five more gallons of water shooting straight up and actually splashing the ceiling. ****!

Ok, now I'm back on the geyser hole waiting for the system pressure to bottom as the hose in the sink does its thing, and I'm kneeling in a good inch of water spread throughout the 10x6 foot space. The one thing going for me is the rooms surrounding the utility room have raised floors a couple of inches thick above the slab while the utility room floor is bare concrete. So the water is mostly staying inside the room though slowly seeping outwards through the wall framing and trying to leak out under the raised floors. As soon as the pressure bottoms I closed all of the system ball valves to keep water where it was, then ran out to the garage and grabbed our wet vac, ran it back to the utility room, and started vacuuming all the water. Got that done, rolled the vac back to the garage, then grabbed three 20" box fans out of storage and got them fired up drying out what was wet.

At that point everything was more or less stabilized, so I changed into dry clothes then drove to our local Aubuchon Hardware 3 miles away and picked up a 1/4 MPT x 3" brass nipple - because nobody carries stainless steel nipples that size, aside from a Grangers store 30 miles away. Extracted the broken stub, taped and installed the new nipple and screwed the pressure switch on, tightened everything down then fired up the pump circuit. After flushing the system 'til it ran clean I put everything back to "normal positions".

This is the second time this has happened since we had the well drilled back in 2010, and this one is on me, as I should have replaced the original failed brass nipple with a stainless steel model instead of another brass one that failed today. At least I have ordered an SS nipple now, and I intend to shut the system down and replace the brass one when the SS nipple gets here. Not going through this a third time, dammit!

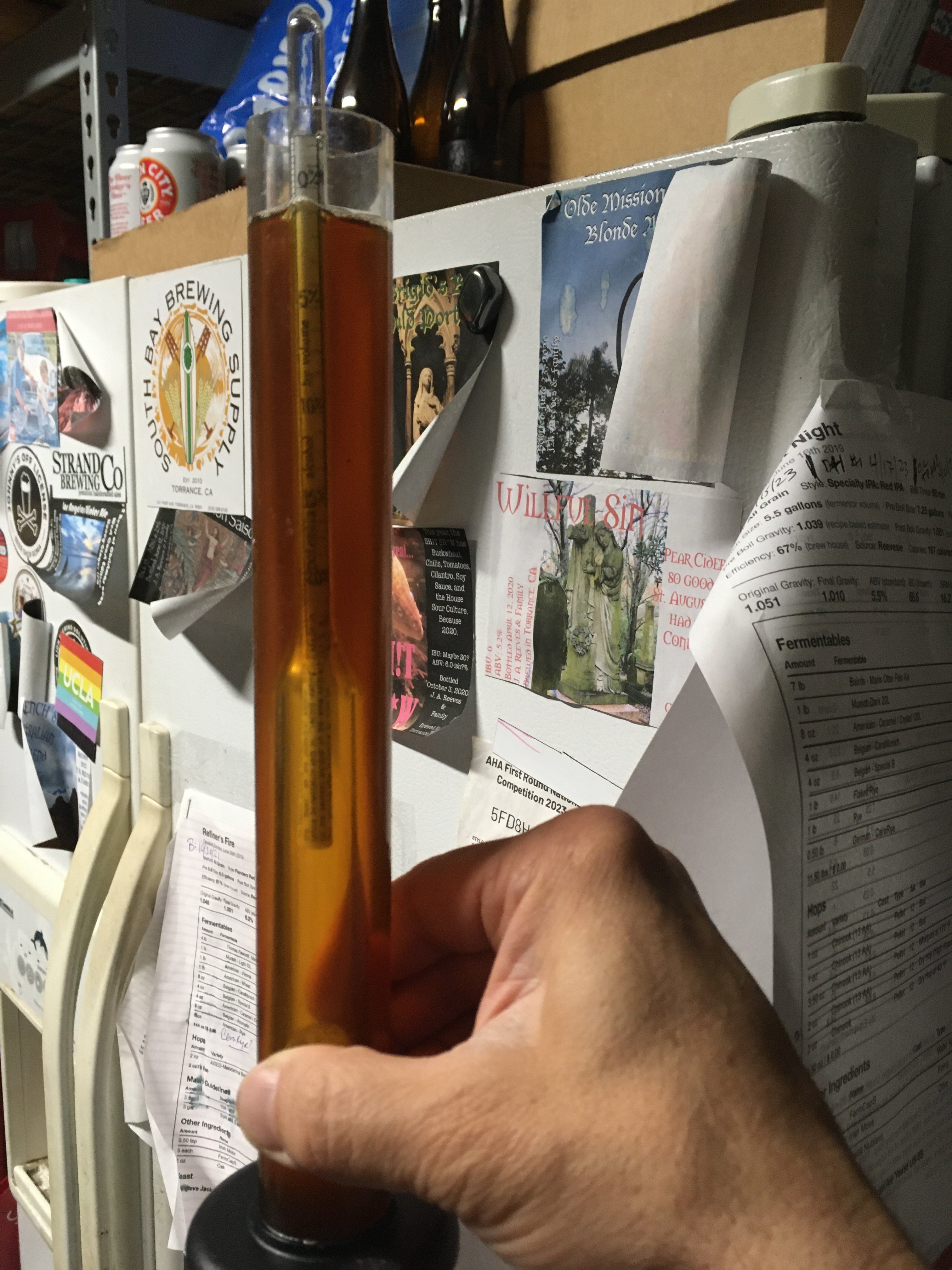

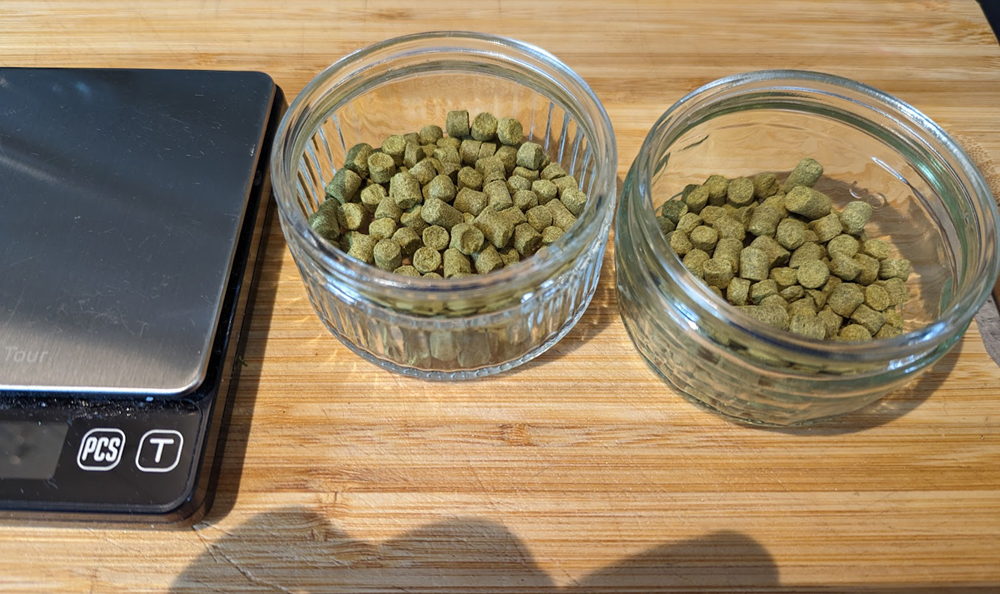

I

so need a beer!

Cheers!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)