Went into the fermenter at 1.091, so at least something went right with this screwy brewday! SG per the recipes I kind of glommed together is supposed to be about 1.081, so that was a big overshot. I'm going to try this again next time I brew the House American Strong; I occasionally do a reduction for that, so maybe this method will negate that step.I forget about the BIAB systems. I'm old school. I hope it is great.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Well technically NY state...close friend of mine had a property up near Keuka lake (one of the finger lakes) that he cleared a few acres for a house that he was planning to build. He had the oak and cherry milled up into 1 1/4" planks for future cabinets. Few years later he decided to sell the land and he told me if I wanted to truck up there I could have whatever I can grab. So I took my trailer and drove up. Grabbed close to 1000 board feet of oak and probably a few hundred board feet of cherry, maxed out my trailer and headed back to FL.Where did you get the oak?

I have a woodworking shop in my garage along with my brewery, so I always have off cuts stacked here and there. I knew the oak was clean, as in nothing sprayed on it or treated with anything.

It was the chemicals I was concerned about (Home Depot). I have 4 live edge oak slaps I got from a friend near the Oklahoma and Texas boarder. We cut down a damaged tree and his neighbor has a portable sawmill and we cut it in to 11 slabs 11' x 2' x 3". I have them stacked in the garage drying.Well technically NY state...close friend of mine had a property up near Keuka lake (one of the finger lakes) that he cleared a few acres for a house that he was planning to build. He had the oak and cherry milled up into 1 1/4" planks for future cabinets. Few years later he decided to sell the land and he told me if I wanted to truck up there I could have whatever I can grab. So I took my trailer and drove up. Grabbed close to 1000 board feet of oak and probably a few hundred board feet of cherry, maxed out my trailer and headed back to FL.

I have a woodworking shop in my garage along with my brewery, so I always have off cuts stacked here and there. I knew the oak was clean, as in nothing sprayed on it or treated with anything.

Dave Sarber

Unindicted Co-conspirator

Definitely stay away from the walnut. Don't know about cherry or mahogany, the maple will probably give little or no taste.First time posting to this topic, today I smoked some oak cubes in our oven @ 400° for 3 hours. Once finished, after they cooled, I weighed out 3 oz of cubes and put them to soak in some bourbon for an upcoming RIS recipe I'm following from Kal at the electric brewery. Plan to brew in about 3 weeks or so, the cubes should be good and ready for the secondary by then.

View attachment 727858

View attachment 727859

View attachment 727860

View attachment 727861

View attachment 727862

View attachment 727863

I have quite a bit left over, so in the drawer they go for another brew day.

View attachment 727864

Might try a rum based soak for the next brew, and I have tons of wood scraps...cherry, maple, walnut, mahogany. Need to read up on what flavor each wood can impart to a beer.

For experimenting with different woods, whittle a toothpick and suck on it awhile.

Had an IPA that had cedar added to it once. Thought it tasted OK, it had a bit of a fresh hamster cage aroma.

hout17

Crush it REAL Good

First time posting to this topic, today I smoked some oak cubes in our oven @ 400° for 3 hours. Once finished, after they cooled, I weighed out 3 oz of cubes and put them to soak in some bourbon for an upcoming RIS recipe I'm following from Kal at the electric brewery. Plan to brew in about 3 weeks or so, the cubes should be good and ready for the secondary by then.

View attachment 727858

View attachment 727859

View attachment 727860

View attachment 727861

View attachment 727862

View attachment 727863

I have quite a bit left over, so in the drawer they go for another brew day.

View attachment 727864

Might try a rum based soak for the next brew, and I have tons of wood scraps...cherry, maple, walnut, mahogany. Need to read up on what flavor each wood can impart to a beer.

NICE bandsaw and I can tell the shop area is equally as nice.

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

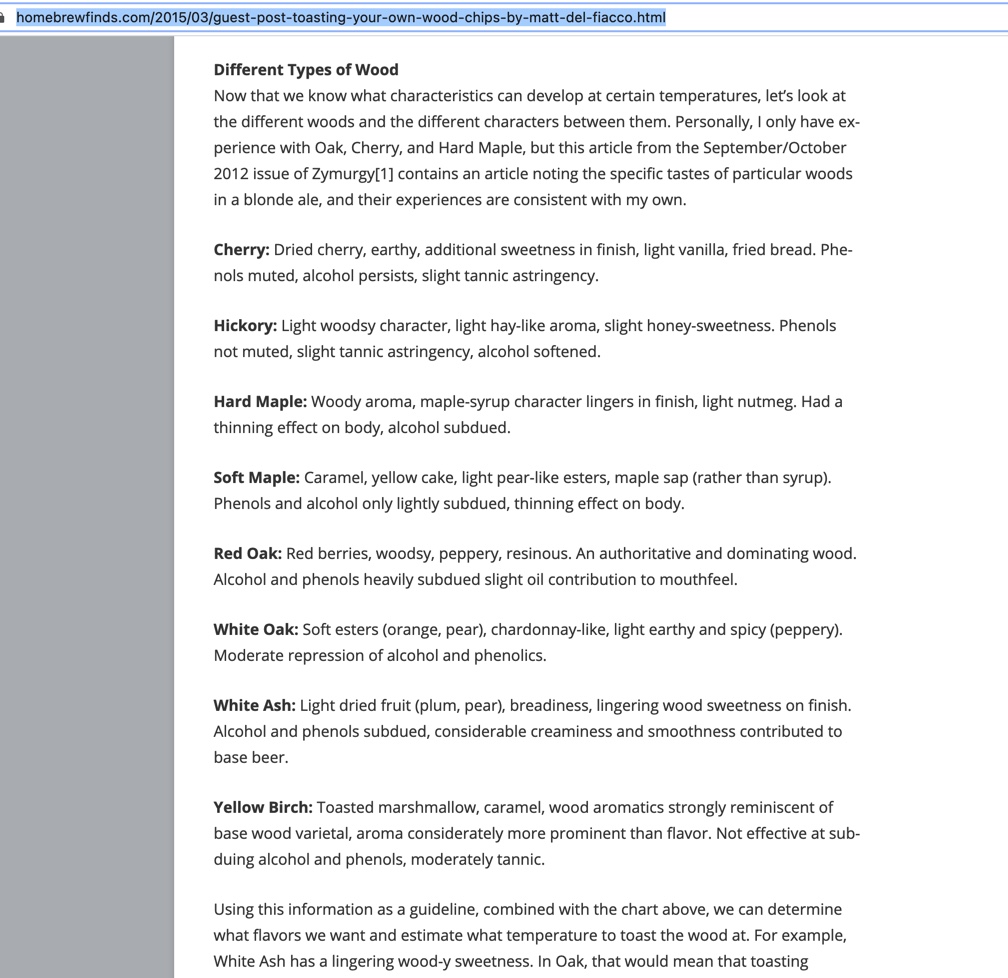

Here's an interesting page I found, it talks about different types of wood and the flavors they can offer.Definitely stay away from the walnut. Don't know about cherry or mahogany, the maple will probably give little or no taste.

For experimenting with different woods, whittle a toothpick and suck on it awhile.

https://www.homebrewfinds.com/2015/...g-your-own-wood-chips-by-matt-del-fiacco.html

And here's a screen shot which talks about different wood types...

That's one idea. I am in the process of converting to all electric also. Trying to figure out what I'm gonna do with burners and tanks as well. The wok idea is a good one. I think I'll give my 205,000 BTU burner a go under my crab boil pot. That will speed that up.you might want to cook a high temp wok dish sometime!

Excuse my ignorance but what do you mean by 4 inch spool with 4 inch height?Put this monster of a hop dropper on my conical. 4 inch spool with 4 inch height. It can probably hold a full mason jar of hops no problem. So ridiculous lol.

Forgot to post this yesterday, but I brewed 5.5 gallons of a pilsner

Nailed the mash in temperature, but fudged up the sparge... got stuck about 20minutes in, so i opened the valve on the mash tun more and milled grain poured into my kettle

Also broke the airlock at then end of it all and had to speed over to the brew shop before they closed. It was a day

Nailed the mash in temperature, but fudged up the sparge... got stuck about 20minutes in, so i opened the valve on the mash tun more and milled grain poured into my kettle

Also broke the airlock at then end of it all and had to speed over to the brew shop before they closed. It was a day

bracconiere

Jolly Alcoholic - In Remembrance 2023

That's one idea. I am in the process of converting to all electric also. Trying to figure out what I'm gonna do with burners and tanks as well. The wok idea is a good one. I think I'll give my 205,000 BTU burner a go under my crab boil pot. That will speed that up.

don't thank me, thank Alton Brown, he did a show on how to get proper what i guess is called "Wok-a"

hout17

Crush it REAL Good

Bottled up a Blue Moon Clone today.

Getting prepped for summer yard wars with my yard!

Getting prepped for summer yard wars with my yard!

He has one of the glass shelves on the floor in front of the fridge.That's one shiny floor

So, I have been checking the airlock on the New Zealand Pale Ale I brewed on Saturday and I have not seen any activity or smelled any good smells, so I open the fermenter this afternoon and no krausen, no krausen ring, still smells like raw wort. So much for my pack of White Labs 007, Dry English Ale, admittedly my favorite yeast culture. Dropped the back-up plan into the wort and am hoping to see changes by tomorrow. Always have a pack of SafAle-05 in the freezer!

- Joined

- Nov 26, 2013

- Messages

- 9,924

- Reaction score

- 24,085

I have 4 live edge oak slaps

I hate oak slaps. Too many splinters.

In other news, today I made yet another (#26) batch of @Yooper 's Haus Pale, in the FC with WY1450 tuned to 64F.

Tapped the Lemondrop Blonde that I brewed a few weeks ago; it's an okay ale, just not exactly what I wanted it to be. Just your garden variety blonde. Oh well it will be drunk. Next time I will delete the bittering hops (in this case .5oz Cascade) and do only late additions.

Tapped the Lemondrop Blonde that I brewed a few weeks ago; it's an okay ale, just not exactly what I wanted it to be. Just your garden variety blonde. Oh well it will be drunk. Next time I will delete the bittering hops (in this case .5oz Cascade) and do only late additions.

Maybe give it the Corona treatment? A slice of lemon/lime to add acidity?

- Joined

- Feb 19, 2017

- Messages

- 979

- Reaction score

- 1,238

I am completely recovered and doing fine. Thanks for the thoughts!!@seatazzz Just checking in to confirm that from your posting, fingers crossed that the bout of covid was not horrible and behind you?

I am completely recovered and doing fine. Thanks for the thoughts!!

Transferred my piwo grodziskie to the keg for lagering and slow carb. Hit 3.3% abv and enjoyed the taste in my sample. It's my first time making one. I have high hopes! I even went traditional and used some white willow bark and all lubelski hops!

Brewed. Small batch all centennial double ipa. I overshot the gravity a bit and might end up in the 9.3% range instead of the 8.2ish I wanted it to be.

Whoops

Whoops

I hate Pale Ale too many hops...I hate oak slaps. Too many splinters.

In other news, today I made yet another (#26) batch of @Yooper 's Haus Pale, in the FC with WY1450 tuned to 64F.

After an absolutely sh*tty day at work, sitting here enjoying some of my own homebrew and pondering on the work ethic of people today. We've grown enough that I need an assistant; I've gone through three temps and one solid hire that can't handle what I have to teach. What I do can't be learned in a classroom environment (container dispatching from very very very busy Seattle/Tacoma ports) and can only be learned through experience, which I have 14 very successful years of. Last one, that lasted three weeks, walked out this morning without a word to anyone after seeing me deal with a driver who got an overweight ticket. And, trying not to be too much of a b*tch, this woman was a Karen to the nth degree that none of my co-workers could stand listening to. Fortunately the big bosses have my back, and know they would be screwed without me.

One of the many reasons I'm really glad I homebrew; after a day like today I would be running to the corner store for replacements in a nanosecond, if I didn't have the well-filled kegerator in my garage. Carry on, I'll just be sitting here in the corner sipping on something tasty and trying not to think about the next few days.

One of the many reasons I'm really glad I homebrew; after a day like today I would be running to the corner store for replacements in a nanosecond, if I didn't have the well-filled kegerator in my garage. Carry on, I'll just be sitting here in the corner sipping on something tasty and trying not to think about the next few days.

Happy to read you're apparently fully recovered and kicking ass

hout17

Crush it REAL Good

-Milled my grains with my new crop duster mill

-treated my brewing water with half a campden tablet

-Going to brew an IPA with citra, cascade, and centennial hops this afternoon

-treated my brewing water with half a campden tablet

-Going to brew an IPA with citra, cascade, and centennial hops this afternoon

Be careful walking away from that. Stepped away for a second to grab something during a boil on a jet burner, came back to smoke instead of steam after all the liquid was gone. Crabs were fine since I was close to time but the stainless pot was scorched to hell and warped slightly on the bottom. Granted, I had an excuse to buy an even bigger pot for beer and now have a dedicated crabber, but it still suckedI think I'll give my 205,000 BTU burner a go under my crab boil pot. That will speed that up.

- Joined

- Feb 23, 2021

- Messages

- 497

- Reaction score

- 830

CTRL-C CTRL-V!!Kegged with my little guy

Rearranged the keezer so I can move a fermenter into it for cold crashing this weekend (already let it free-rise to 71F for the finishing touches). Going to experiment with the 2-day dry hop at 36F method and then keg/gas.

Similar threads

- Replies

- 66

- Views

- 3K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 3K