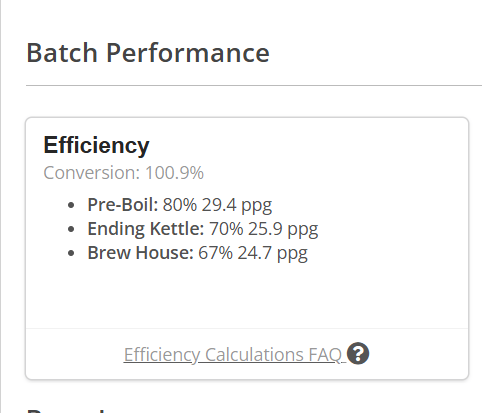

brewzilla brewhouse, brew'n'water, and software is brewers friend- 55% ending kettle efficiency. ouch. has happened multiple times recently. thought i wasnt crushing my wheat or rye, which are in alot of my beers. but after getting a separate mill for .020 milling of those, no change. main mill is set at roughly .030 recently. typically shoot for 5.4pH. 7.25 gals of water, yesterday was 12# of grain- 7 base, 2 wheat, 2 vienna, 1 carafoam.

did 25min at 146ish, then 20 at 157ish, then 10 min mashout. pre boil gravity was only 1036/1037. i had about 6.25 gals after squeezing the **** out of the bag. after boiling down to just under 6gals, i'm at like 1038/1039 OG. ugh.

i had recirc going pretty slow. maybe too slow?

i slowly lower bag into brewzilla, hard to believe it could be dough balls.

double crush? take the main mill down to like .025 ?

the reason im frustrated, is that i used to get like 65-70%. besides mill settings, i dont recall any real difference in process. maybe i'm doing recirc too slow? i honestly cant think of where this came from. i know grain is cheap. but i'd prefer to figure out why i've dropped roughly 10%. becomes pain in the ass to run old recipes as i cant rely on them.

did 25min at 146ish, then 20 at 157ish, then 10 min mashout. pre boil gravity was only 1036/1037. i had about 6.25 gals after squeezing the **** out of the bag. after boiling down to just under 6gals, i'm at like 1038/1039 OG. ugh.

i had recirc going pretty slow. maybe too slow?

i slowly lower bag into brewzilla, hard to believe it could be dough balls.

double crush? take the main mill down to like .025 ?

the reason im frustrated, is that i used to get like 65-70%. besides mill settings, i dont recall any real difference in process. maybe i'm doing recirc too slow? i honestly cant think of where this came from. i know grain is cheap. but i'd prefer to figure out why i've dropped roughly 10%. becomes pain in the ass to run old recipes as i cant rely on them.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)