You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you using for oxygenation?

- Thread starter fuzzybee

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,967

- Reaction score

- 6,216

I use a refillable O2 cylinder, regulator, tubing, and a wand that terminates in a 0.5 micron stainless steel stone. A real regulator (in contrast to the kind used with the disposable home depot type cylinders) allows you to set the flow rate. If you want to measure the actual dissolved O2 in the wort, you need a DO meter.

fuzzybee

Well-Known Member

Thanks! Should something like this (Blichmann Oxygen Flow Regulator | MoreBeer) suffice for the regulator?

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,967

- Reaction score

- 6,216

Thanks! Should something like this (Blichmann Oxygen Flow Regulator | MoreBeer) suffice for the regulator?

Yes. One of my regulators is that same model and it works great.

Panderson1

Well-Known Member

- Joined

- Dec 23, 2020

- Messages

- 371

- Reaction score

- 156

Lowes and Home Depot have been out of stock (red Cans) for like a year. I'm going to ask the guys at my CO2 place today.

- Joined

- Oct 12, 2020

- Messages

- 3,568

- Reaction score

- 6,947

Just something to consider: Blichmann Premium Inline Oxygenation Kit | MoreBeer

If you keg and force carb and ever considered the QuickCarb, you essentially get it with this unit without paying and extra $100 or so for pump and holder. That's what I did as I already had 2 diaphram pumps for racking, of the same spec as the one Blichmann sells.

If you keg and force carb and ever considered the QuickCarb, you essentially get it with this unit without paying and extra $100 or so for pump and holder. That's what I did as I already had 2 diaphram pumps for racking, of the same spec as the one Blichmann sells.

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

I've run into the same issue. Check your local hardware or auto parts stores. I found 2 tanks at NAPA.Lowes and Home Depot have been out of stock (red Cans) for like a year. I'm going to ask the guys at my CO2 place today.

This is what I use to oxygenate my wort,and it seems to work fine. Turn regulator until I see a steady stream of bubbles and set timer for 60 seconds.

- Joined

- May 28, 2018

- Messages

- 3,264

- Reaction score

- 2,977

I use an medium/small Airgas exchange cylinder with a medical style regulator that looks a lot like the Blichman, cost about $35 new on ebay. There is more than one type of mounting system, some threaded, and some O ring style, so make sure regulator matches tank if you go that route.

I have a triclamp mounted injector that I put on conical fementor when filling w wort. Cost about $100 on morebeer. It is cool, but the stainless stone on wand tube they sell for $30 works just as well, though might not technically be as sanitary.

In either case, I run O2 at rate of 1 liter/min (according to the regulator) for about two minutes.

I have a triclamp mounted injector that I put on conical fementor when filling w wort. Cost about $100 on morebeer. It is cool, but the stainless stone on wand tube they sell for $30 works just as well, though might not technically be as sanitary.

In either case, I run O2 at rate of 1 liter/min (according to the regulator) for about two minutes.

I do inline oxygenation at it runs at 1/2-1 lpm with a medical style regulator the entire time the wort is being transferred from the chiller into the fermenter, all of it going in is usually foam.

Gilbert Spinning Horse

Well-Known Member

- Joined

- May 28, 2018

- Messages

- 179

- Reaction score

- 249

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,967

- Reaction score

- 6,216

You can count how long you run the drill for.

The problem with dissolving O2 from air is that you can run that drill forever and never get higher than roughly 8 ppm DO.

Gilbert Spinning Horse

Well-Known Member

- Joined

- May 28, 2018

- Messages

- 179

- Reaction score

- 249

Do you need to get more?

I've read that with pure oxygen you run a risk of over oxygenating to wort.

I've read that with pure oxygen you run a risk of over oxygenating to wort.

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,967

- Reaction score

- 6,216

Do you need to get more?

Depends on the wort and the goal, but very often, yes.

I've read that with pure oxygen you run a risk of over oxygenating to wort.

It's possible, but unlikely if paying attention to time and flow rates, or better yet, measuring with a DO meter.

I use a SS aeration “stone” connected to a medical O2 tank with a regulator.I would like to start oxygenating my wort before pitching yeast, but i want to do so in a measurable capacity. What setup are y'all using for that?

If you have any contacts in medical supplies, etc. , you can get a full tank without an Rx.

It’ll last a long time!

Pablo 54

Well-Known Member

I've gotten pretty good at aiming the tube about 4 feet above the fermenter and just splashing away. Depending on the beer, I'll use a fish tank pump.

I would like to start oxygenating my wort before pitching yeast, but i want to do so in a measurable capacity. What setup are y'all using for that?

I have one of those aquarium pump system with an inline filter and a carb stone. I have not used it in a few years (except maybe for some high gravity batches?). I am often using dry yeast, and I buy into the idea that oxygenation is not a requirement with dry yeast. I also brew a lot of 2.5 gallon batches, or 5 gallon batches split with 2 yeasts. Those smaller sizes give me a bit more wiggle room. I do generally pour my wort through a strainer into the fermenter, so there is some oxygenation that occurs.

As far as using liquid yeast in a 5 gallon batch: One thing that stood out to me from an Escarpment Labs webinar on their YouTube channel was a statement "Your goal is not to oxygenate the wort; your goal is to oxygenate the yeast." This clicked with me and my use of Shaken-not-Stirred "vitality" starters. I tend to believe that if I pitch my liquid yeast into an oxygen rich starter environment then I have accomplished my goal of "oxygenating the yeast."

I will add that my view on fermentation health is that their is a matrix of factors at play such as gravity, volume, temperature, pitch rate, yeast health, oxygenation, and probably some others. I try to take into account the factors of the specific batch and ensure that I am checking enough of those boxes. A fresh pack of Imperial yeast into a 5-gallon batch of Blonde Ale is quite different than a single 4 month old pack of White Labs into a 6-gallon batch of 1.070 IPA.

fuzzybee

Well-Known Member

Interesting. I usually make starters on a stir plate. Should that oxygenate enough?I have one of those aquarium pump system with an inline filter and a carb stone. I have not used it in a few years (except maybe for some high gravity batches?). I am often using dry yeast, and I buy into the idea that oxygenation is not a requirement with dry yeast. I also brew a lot of 2.5 gallon batches, or 5 gallon batches split with 2 yeasts. Those smaller sizes give me a bit more wiggle room. I do generally pour my wort through a strainer into the fermenter, so there is some oxygenation that occurs.

As far as using liquid yeast in a 5 gallon batch: One thing that stood out to me from an Escarpment Labs webinar on their YouTube channel was a statement "Your goal is not to oxygenate the wort; your goal is to oxygenate the yeast." This clicked with me and my use of Shaken-not-Stirred "vitality" starters. I tend to believe that if I pitch my liquid yeast into an oxygen rich starter environment then I have accomplished my goal of "oxygenating the yeast."

I will add that my view on fermentation health is that their is a matrix of factors at play such as gravity, volume, temperature, pitch rate, yeast health, oxygenation, and probably some others. I try to take into account the factors of the specific batch and ensure that I am checking enough of those boxes. A fresh pack of Imperial yeast into a 5-gallon batch of Blonde Ale is quite different than a single 4 month old pack of White Labs into a 6-gallon batch of 1.070 IPA.

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,967

- Reaction score

- 6,216

Interesting. I usually make starters on a stir plate. Should that oxygenate enough?

Keep in mind that when you make a normal starter (one that increases the cell count), the yeast use whatever O2 is available to make sterols to build cell wall material, which enables budding, i.e. the thing that increases the cell count in the starter. Then, after the new, higher cell count is pitched into the main batch wort, it will need to increase much more than it did in the starter. So it will need to rebuild sterol reserves for all the budding it still needs to do. I would not count on the cells already having all the sterol reserves needed (i.e. left over from the starter stage).

fuzzybee

Well-Known Member

Thanks. Makes sense.Keep in mind that when you make a normal starter (one that increases the cell count), the yeast use whatever O2 is available to make sterols to build cell wall material, which enables budding, i.e. the thing that increases the cell count in the starter. Then, after the new, higher cell count is pitched into the main batch wort, it will need to increase much more than it did in the starter. So it will need to rebuild sterol reserves for all the budding it still needs to do. I would not count on the cells already having all the sterol reserves needed (i.e. left over from the starter stage).

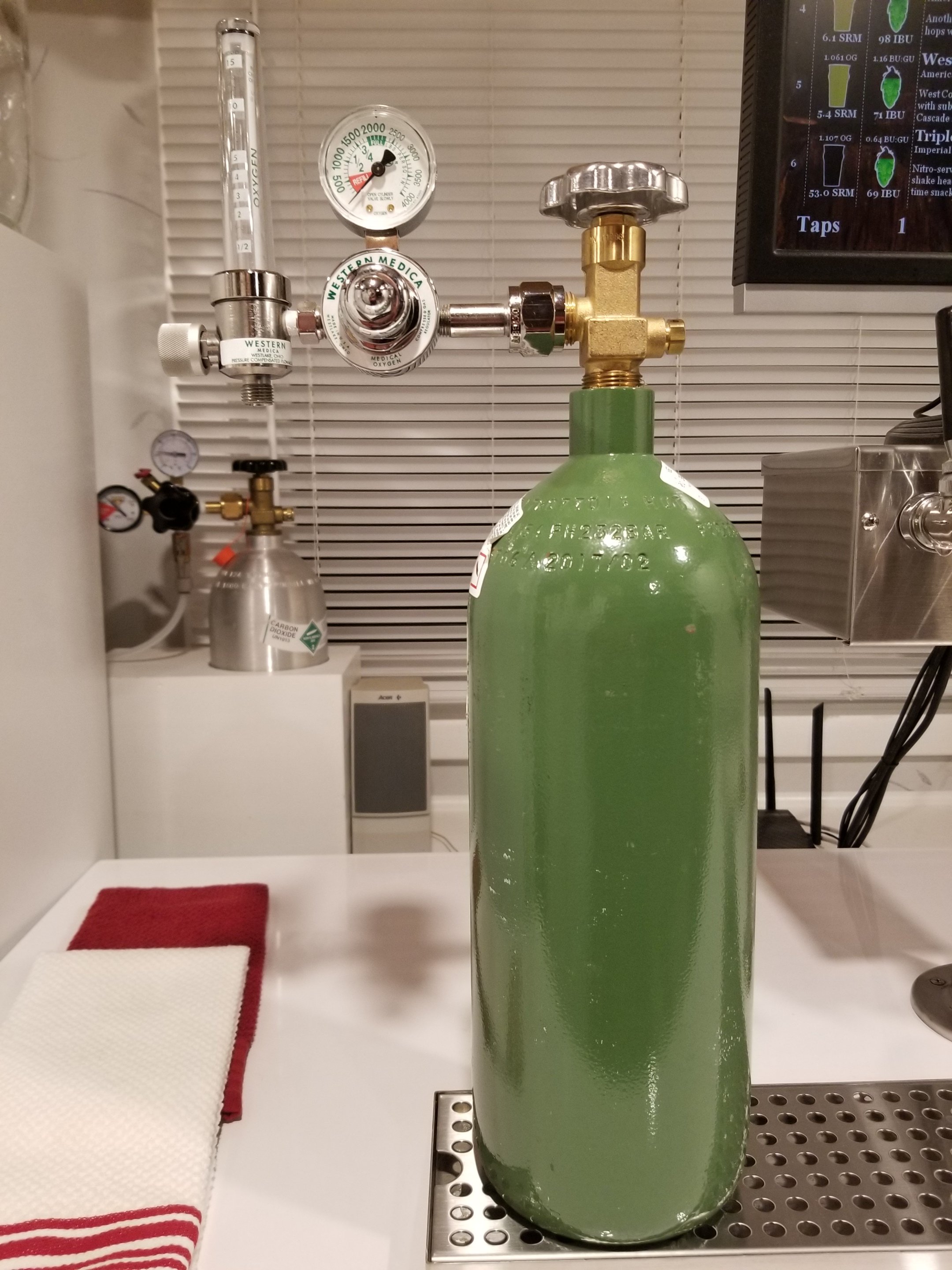

20cf cylinder with a "medical style" flow meter...

And that's a legit flow meter. I was hooked up to one of those in hospital once...

Cheers!

And that's a legit flow meter. I was hooked up to one of those in hospital once...

Cheers!

Interesting. I usually make starters on a stir plate. Should that oxygenate enough?

I would ask, enough for what? Are you pitching 300B cells of healthy yeast into your 1.050 Pale Ale, or did you only build up 150B cells that you are pitching into a 1.090 stout or into a 1.055 lager that will be fermented at 48F?

fuzzybee

Well-Known Member

Yes?I would ask, enough for what? Are you pitching 300B cells of healthy yeast into your 1.050 Pale Ale, or did you only build up 150B cells that you are pitching into a 1.090 stout or into a 1.055 lager that will be fermented at 48F?

I'm speaking more in generalities. It appears a starter can't substitute for proper oxygenation.

- Joined

- Nov 13, 2019

- Messages

- 546

- Reaction score

- 377

O2 tank with a flowmeter that pumps out between 1/4 lpm to 10. I do a 1/4 lpm for 4 minutes vs the 1 lpm that everyone does cuz i feel it difuses into the wort better of it goes slower. Tanks do last forever lol.

Enough for the starter for sure, but as already concluded not for a massive amount of wort to build cell count up.Yes?

I'm speaking more in generalities. It appears a starter can't substitute for proper oxygenation.

Oxygenation is not as critical as starter for proper pitch rates, but it all helps when working the harder stuff like getting a big beer to finish or getting a perfectly crisp lager.

Speaking of adding oxygen, has anyone noticed a shortage in those small red oxygen tanks sold in hardware stores? They have become hard to find here south of Boston.

MadProphet

Member

Can't find them anywhere. Drug out my o2 concentrator for this next batch.

monkeymath

Well-Known Member

- Joined

- Jan 18, 2019

- Messages

- 753

- Reaction score

- 951

I'm not entirely comfortable keeping an O2 canister in my apartment or basement. Am I being paranoid? Or is everyone brewing in their garages and stuff?

Quentin Nelson

Active Member

- Joined

- Dec 29, 2018

- Messages

- 31

- Reaction score

- 32

Medical O2 regulator like this always available on eBay or Amazon. Maybe even less on Craigslist. Look for a full bottle on CL, with a seal strip is nice. Even a small one will last for years if you remember to turn the valve off. I use the .5 micron stainless steel “stone” for about two min at 1.5-2.0 LPM. Then remove stone from threaded stainless wand, rinse & store it in a 4 oz plastic bottle of whiskey. I even oxygenate my 2-liter starters for 20-30 seconds. Read the Yeast book by White & Zainasheff pages 77-83. No way to get enough O2 from “air” which is 80% nitrogen. Not much danger of getting TOO MUCH pure O2 in a couple minutes.

Attachments

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,967

- Reaction score

- 6,216

Medical O2 regulator like this always available on eBay or Amazon. Maybe even less on Craigslist. Look for a full bottle on CL, with a seal strip is nice. Even a small one will last for years if you remember to turn the valve off. I use the .5 micron stainless steel “stone” for about two min at 1.5-2.0 LPM. Then remove stone from threaded stainless wand, rinse & store it in a 4 oz plastic bottle of whiskey. I even oxygenate my 2-liter starters for 20-30 seconds. Read the Yeast book by White & Zainasheff pages 77-83. No way to get enough O2 from “air” which is 80% nitrogen. Not much danger of getting TOO MUCH pure O2 in a couple minutes.

How confident are you in that flow rate? 1.5-2.0 LPM through my 0.5 micron stone would make a hella foam-out-the-top mess.

Quentin Nelson

Active Member

- Joined

- Dec 29, 2018

- Messages

- 31

- Reaction score

- 32

Several green medical oxygen regulators I’ve had all seemed to work about the same. 1.5 LPM might be the sweet spot. I boil in a big Bayou Classic tall kettle; typically 6” below rim after boil. Clear cooled wort, 24” stainless steel wand to hold sintered stone at bottom for gentle stir. (Before pitching yeast) Vigorous tiny bubbles coming to surface, but they do NOT froth up in a “foam”. Might foam more if oxygenating AFTER pitching a lot of active yeast. (BTW, Yes, the Guinness stout tap & handle IS for sale. I have two)

Attachments

Similar threads

- Replies

- 138

- Views

- 12K

- Replies

- 56

- Views

- 2K

Latest posts

-

-

I just poured 42 bottles of HB Dunkelweizen down the drain

- Latest: IslandLizard

-

-

-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)