Change one variable next time. This time it's "the crush" - nothing else.

Aim for a lowish gravity so the grains cost <$4. Mash as normal. Collect accurate preboil volumes and preboil gravities. If you achieve a reasonable gravity then continue on with your brewday. If you fall well short of your preboil gravity then scrap this batch and cut your brewday short (save your effort, time, and hops for next batch); then look at another variable to change on your next batch.

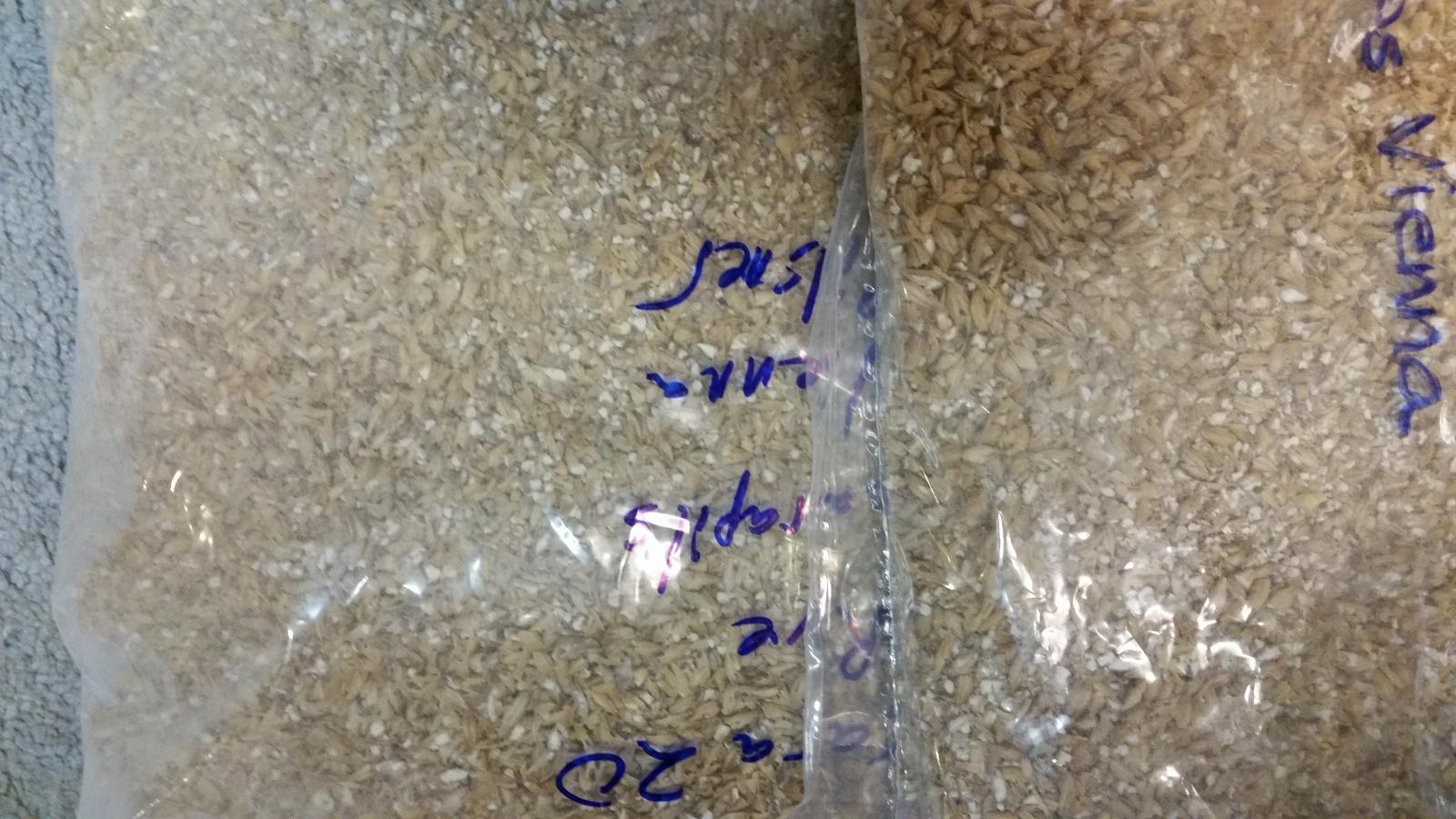

As for the crush, have your LHBS run it through twice for you. Then come home and run it through your blender at 1/4-1/2 lb increments using a pulsing just to ensure you really break it down and end up with fairly small pieces and flour (your grainbag should contain most of it, so no worries). See how this works out in terms of gravity.

As for doughing in, get your strike water where it needs to be and pour your grain into it while stirring (greenbay rackers calculator works exceptionally well). With only a pound or two of grain this should take no more than 10 seconds to get all of the grain in there. Stir it up well and check your mash temp. If you're a little high or a little low, no worries, that can be fixed on future batches because this batch is about reasonable efficiency.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)