BeerBaron1985

The Beer Baron

Hey All,

Since moving to electric, I am now brewing inside. Its supposed to hit 95 F by this Saturday and thats pretty toasty with this humidity. Opposite side of the spectrum winters at its coldest get to -10 F some nights. So far brewing inside this summer, the wort smell SWMBO very much despises, and excess moisture in the basement is a no go. Thankfully running the dehumidifier helps a lot.

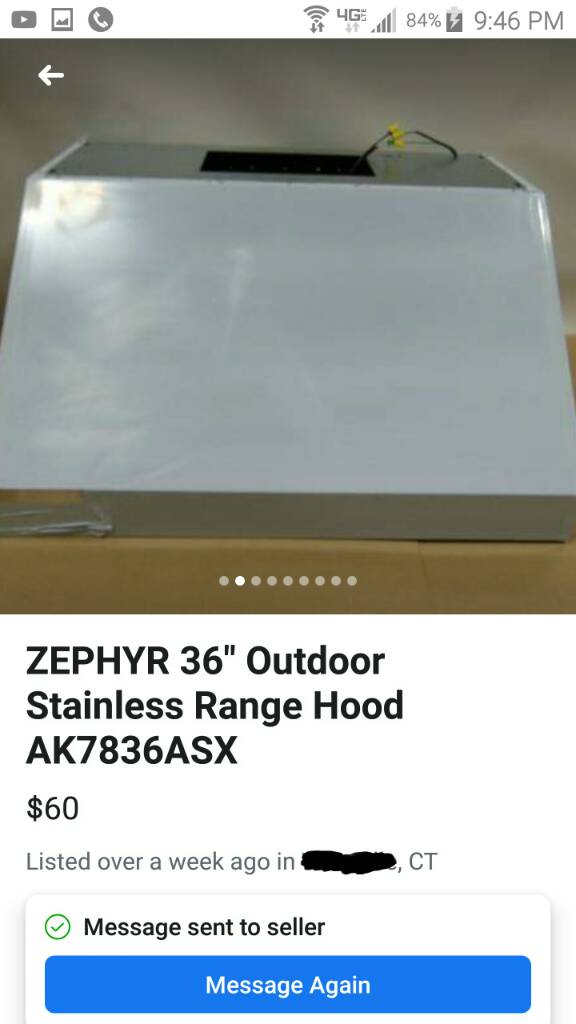

I was on FB marketplace and found THIS stainless hood. The guy told me it has no blower would need to purchase it separately. He runs a liquidator warehouse. He said a contractor sold it off as part of his assets from a job the client didn't want. He had 3 of them. He wanted $60 USD for it. I offered him $40 and he took it. Came with everything, the vent flue, instructions, wiring, baffles, all still in the plastic wrap! The other guy who was there same time as me would have taken all 3, thankfully I got their first!

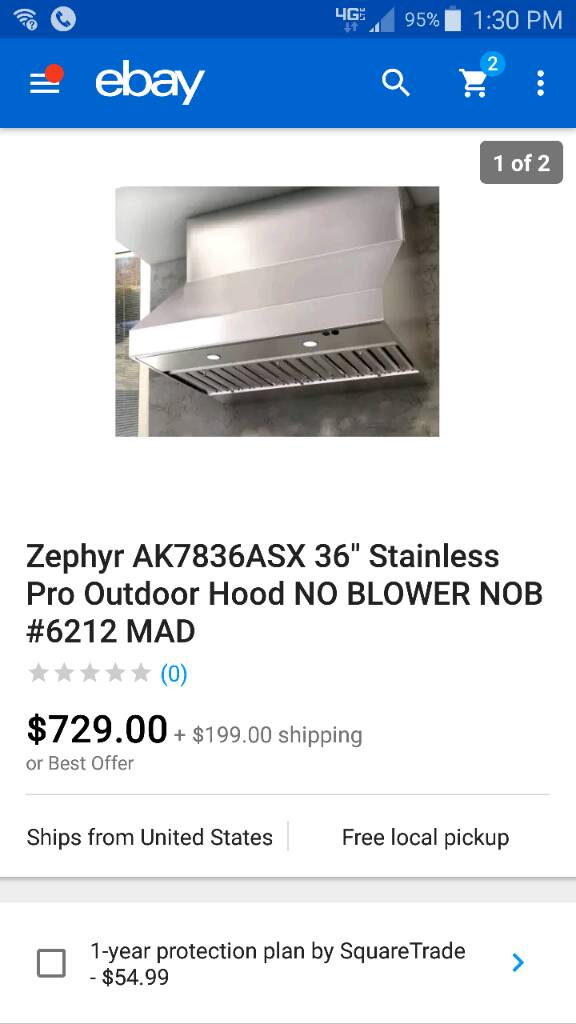

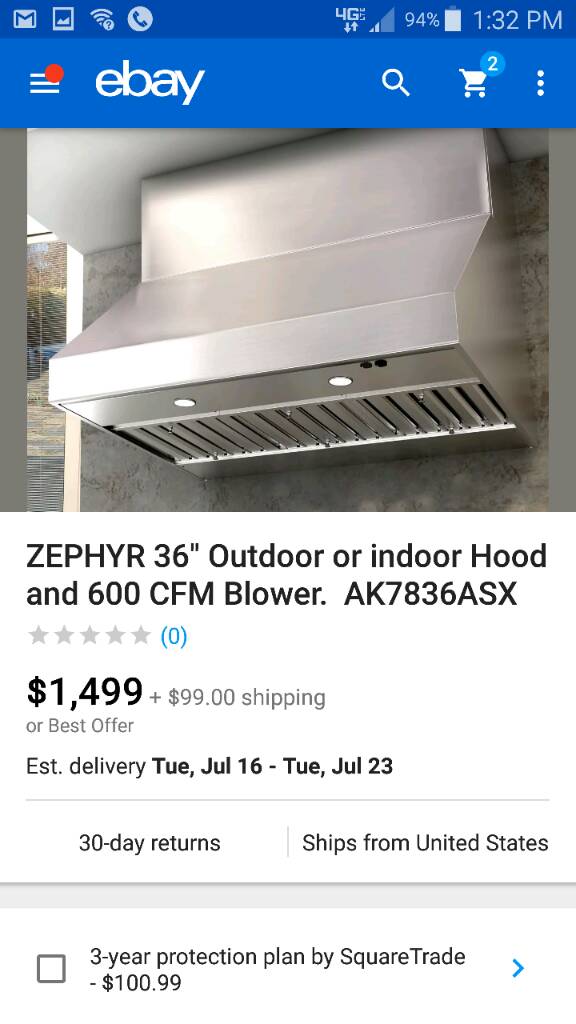

Looks like I did good?? Evilbay has the same model without a blower for over $700 without a blower, and the ones with the blower meant for it retail over $1400-1700 bucks. I'd like to think I'm already ahead of the game!

Anyways onto figuring out where to put downstairs into the brewery area and installing the blower. The 1100CFM dual fan blower meant for this hood is pretty pricey over $370 USD.

My thought is to go with some 10" ducting and vent it out one of the basement windows. This will be a temporary setup and would break out the parts when brewing.

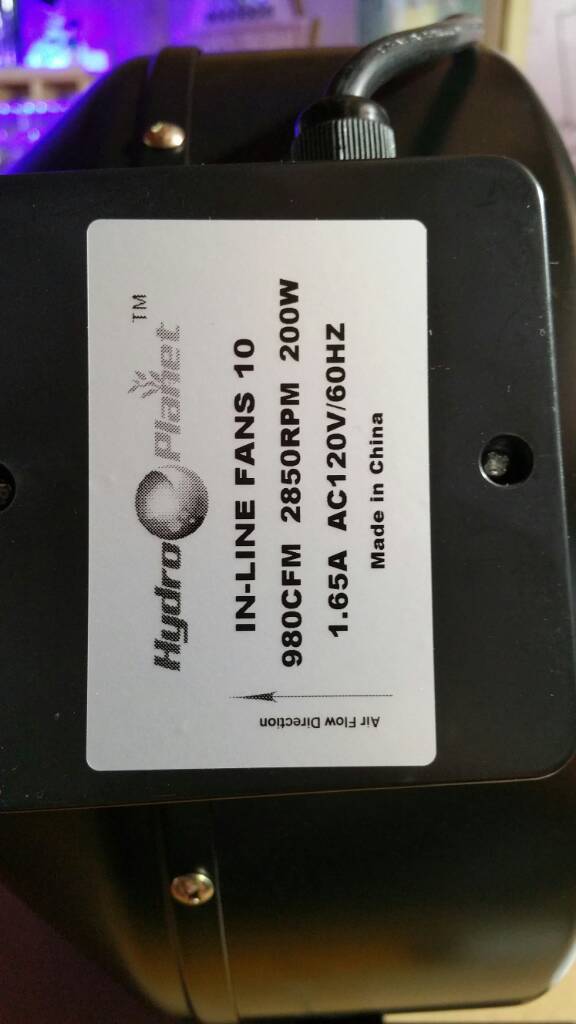

The fan I found is HERE and should have plenty of power for my current application. Just have a 2250W element with a 7.5 gal kettle. Eventually will be upgrading to a 16 gal 3v system down the road so want to have enough rig where I wont need to upgrade later.

I have poured over enough of the vent hood threads to start designing the setup. The found hood was simply a bonus. I would have certainly went the 30qt stainless mixing bowl method like others have.

- This hood is a Type 1, meant for grease and smoke. it does have a drip edge, but no condensate drain. At worst case I would need to add this on one of the corners. doesn't look too difficult at a glance.

- Ideally I would like to have a Type 2 meant for steam evac only

I invite any feedback to make sure I'm on the right track. Pictures to follow.

Since moving to electric, I am now brewing inside. Its supposed to hit 95 F by this Saturday and thats pretty toasty with this humidity. Opposite side of the spectrum winters at its coldest get to -10 F some nights. So far brewing inside this summer, the wort smell SWMBO very much despises, and excess moisture in the basement is a no go. Thankfully running the dehumidifier helps a lot.

I was on FB marketplace and found THIS stainless hood. The guy told me it has no blower would need to purchase it separately. He runs a liquidator warehouse. He said a contractor sold it off as part of his assets from a job the client didn't want. He had 3 of them. He wanted $60 USD for it. I offered him $40 and he took it. Came with everything, the vent flue, instructions, wiring, baffles, all still in the plastic wrap! The other guy who was there same time as me would have taken all 3, thankfully I got their first!

Looks like I did good?? Evilbay has the same model without a blower for over $700 without a blower, and the ones with the blower meant for it retail over $1400-1700 bucks. I'd like to think I'm already ahead of the game!

Anyways onto figuring out where to put downstairs into the brewery area and installing the blower. The 1100CFM dual fan blower meant for this hood is pretty pricey over $370 USD.

My thought is to go with some 10" ducting and vent it out one of the basement windows. This will be a temporary setup and would break out the parts when brewing.

The fan I found is HERE and should have plenty of power for my current application. Just have a 2250W element with a 7.5 gal kettle. Eventually will be upgrading to a 16 gal 3v system down the road so want to have enough rig where I wont need to upgrade later.

I have poured over enough of the vent hood threads to start designing the setup. The found hood was simply a bonus. I would have certainly went the 30qt stainless mixing bowl method like others have.

- This hood is a Type 1, meant for grease and smoke. it does have a drip edge, but no condensate drain. At worst case I would need to add this on one of the corners. doesn't look too difficult at a glance.

- Ideally I would like to have a Type 2 meant for steam evac only

I invite any feedback to make sure I'm on the right track. Pictures to follow.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)