Hey guys,

I did my first all grain brew last week and it was awesome! I was doing it with a 2 keg system, a mash tun and a HL/kettle. I was batch sparging as well. I did this without a pump and i realized like i really do need a pump to make it a lot easier then gravity.

So of course i look to the best site, homebrewtalk to search what i should get.

I found that the March 809-HS pump is a very popular and its not too bad. I found one for a little over $100.

1) What do you guys think of this pump

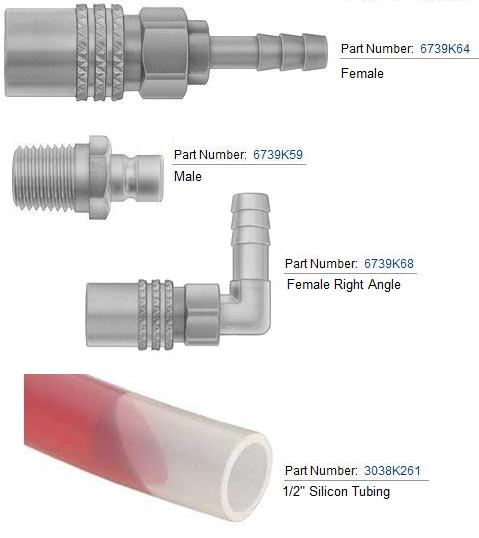

I want to get the quick connections. I was looking at the McMaster connections and also the snaplocks, which is nice because people say they are a lot cheaper and work great.

2) I have 1/2' fittings, I was wondering which one should i pick?

Also can I just put the fittings on the end of the hose and the kegs or do I have to put the connection on the pump as well?

Thank you,

Bob

I did my first all grain brew last week and it was awesome! I was doing it with a 2 keg system, a mash tun and a HL/kettle. I was batch sparging as well. I did this without a pump and i realized like i really do need a pump to make it a lot easier then gravity.

So of course i look to the best site, homebrewtalk to search what i should get.

I found that the March 809-HS pump is a very popular and its not too bad. I found one for a little over $100.

1) What do you guys think of this pump

I want to get the quick connections. I was looking at the McMaster connections and also the snaplocks, which is nice because people say they are a lot cheaper and work great.

2) I have 1/2' fittings, I was wondering which one should i pick?

Also can I just put the fittings on the end of the hose and the kegs or do I have to put the connection on the pump as well?

Thank you,

Bob