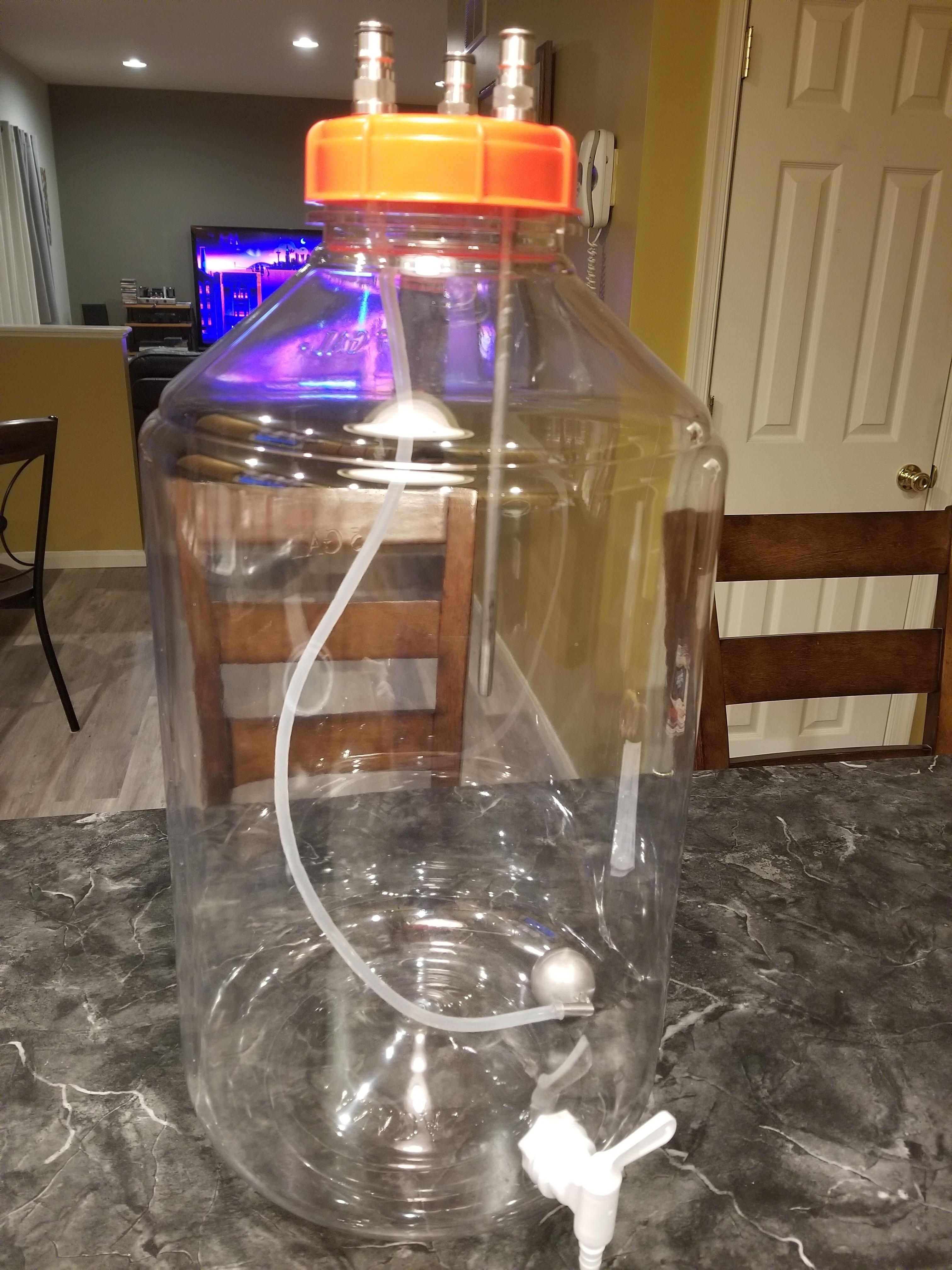

I decided to put one of these together, with an added thermowell, as a cheap backup fermenter for when my conical is in use, but I want to brew a batch in parallel. I don't have to do that often, except during festival season, so this seems like a good (cheap) solution.

So I drilled a test hole in a similar (but throw away) lid with a 7/16" bit. The bulkhead threads had to be literally force threaded (turned) through the hole, which bends the surface of the plastic enough that I don't think the gasket can make a good seal.

I don't own a half inch bit, so before I go buy one, has anyone had any problems with fit/seal with a 1/2" hole?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)