Hex

Well-Known Member

You always seem to be one step ahead of me

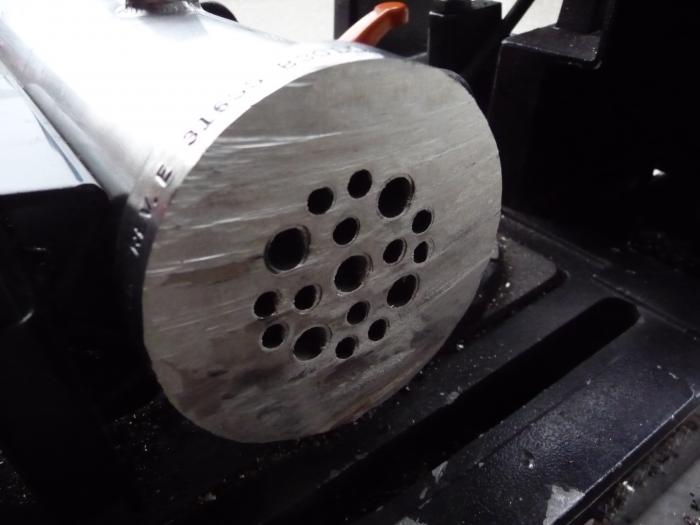

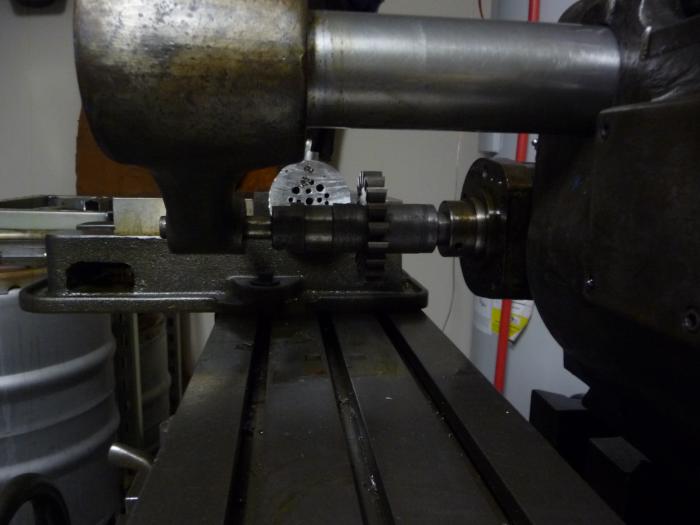

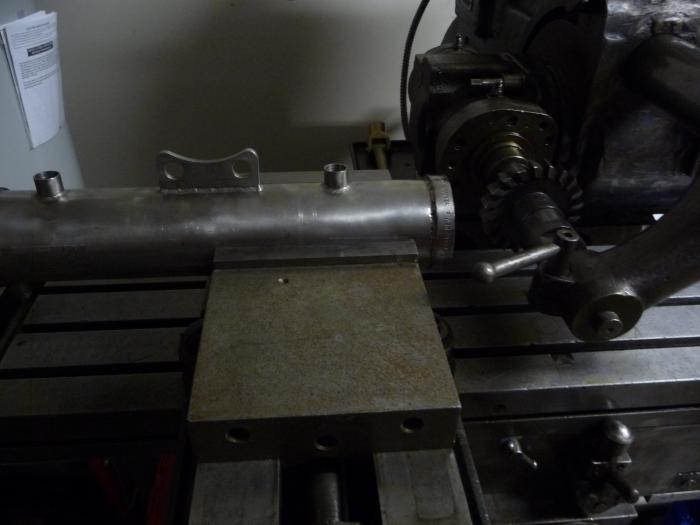

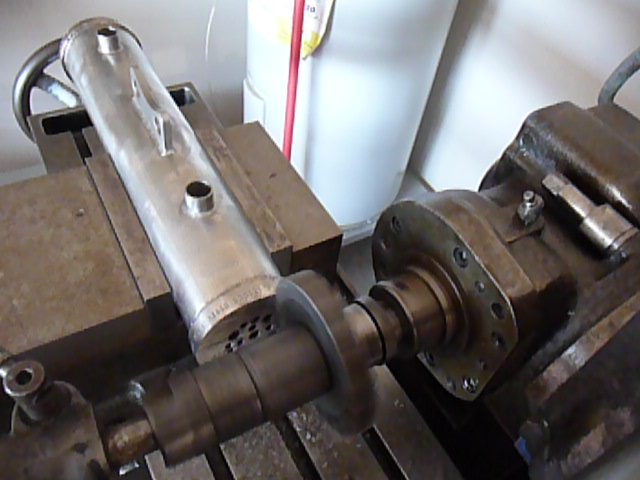

WPStrassburg said:I it doesn't end up working I'll trade you my spare and see i I can make a go at getting it right.... http://s9.photobucket.com/user/w_strassburg/media/Beer/Untitled.jpg.html http://s9.photobucket.com/user/w_strassburg/media/Beer/0603122034a.jpg.html I'm assuming you will be mounting it horizontally with the water connections pointing up to fully flood the shell, but with the wort out at the center of the cap will your tubes only fill to just above half and then become air bound since the air can't be vented from the top tubes above the wort outlet? Would an outlet cap with the connection all the way at the top allow all the air out of the tubes?

By the way, you are right, this design is tough to build but I think it really is the best of all worlds although it still wont be as easy to clean as an IC but it'll be wayyy better than a plate chiller!

WissaBrewGuy............I think you would play hell cleaning said unit, with the wort flowing in the shell, vs. the tubes!