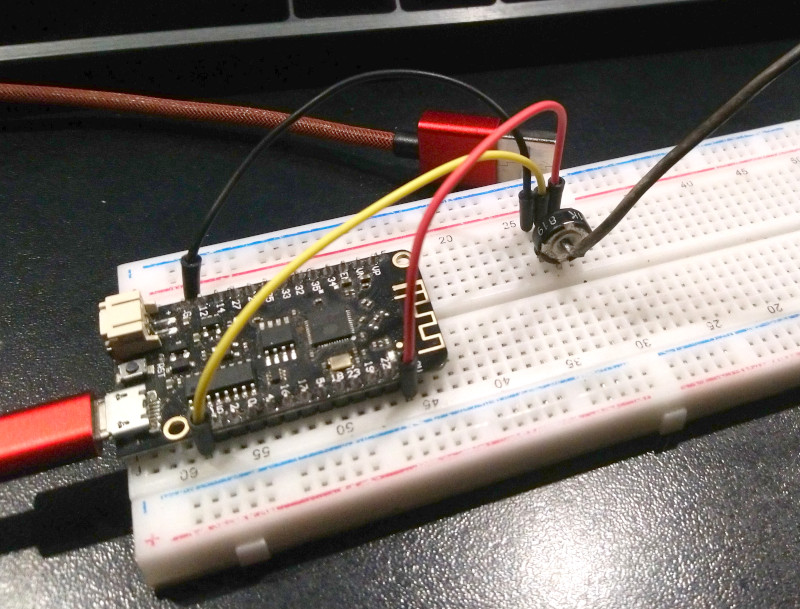

The first step is getting it to work to spec. Cost effective is another good bar to meet.

Agreed, but I think we put reality aside earlier in the thread in the spirit of DIY. To me this is a neat little "green" idea, and I wouldn't be brewing if I wasn't open to fulfilling some pipe dreams here and there. Even if the end product isn't CO2 good enough for beer, perhaps it could be put to another use like in an aquarium or greenhouse.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)