Toxxyc

New and loving it

Hi guys,

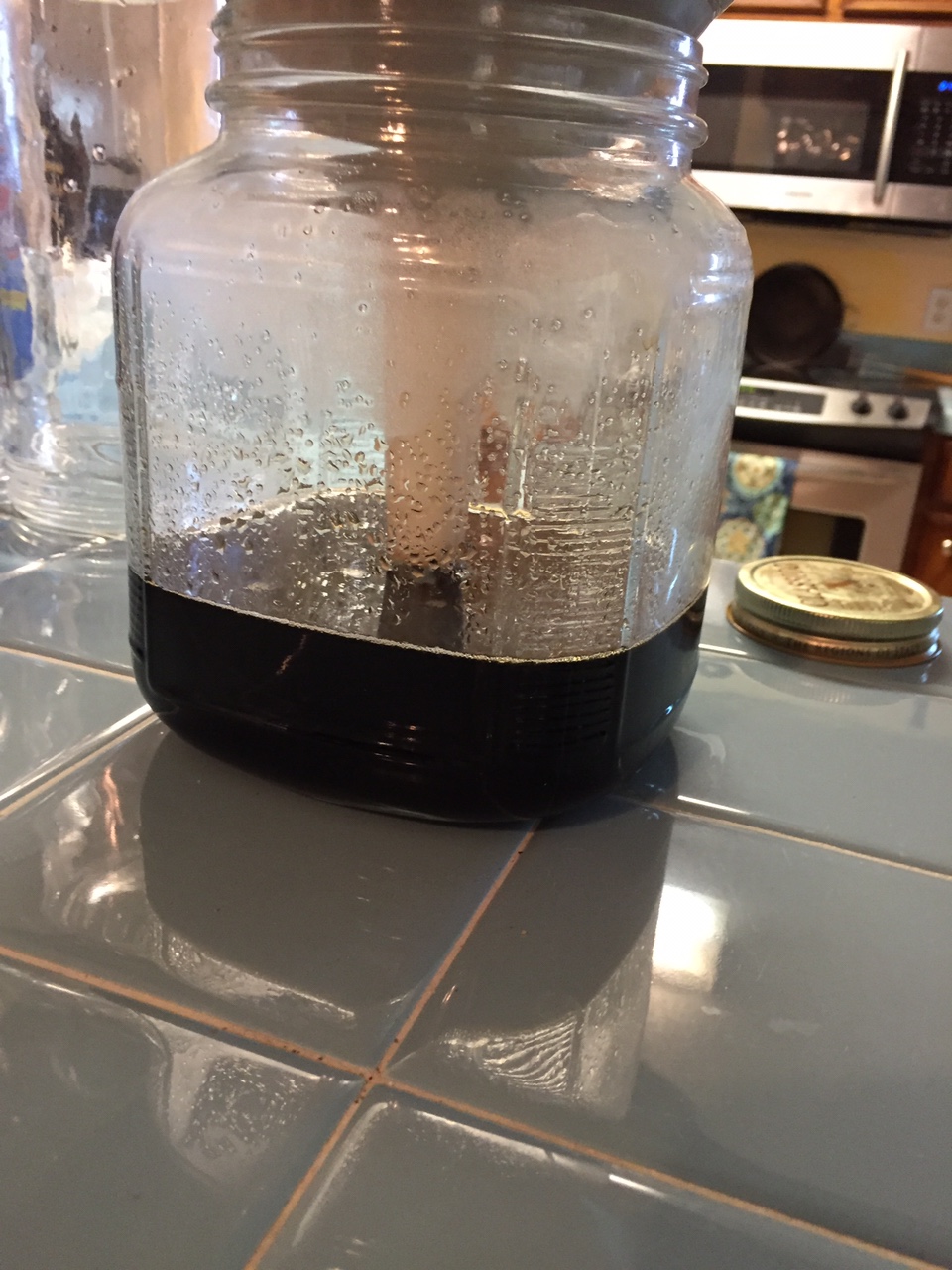

I'm fairly new to AG (after coming from kits) and doing BIAB, and to be honest there's really just one thing that's really bothering me with this process - trub. I don't mind it in the kettle, I don't mind it in the mash, but man, it annoys the living daylights out of me when it gets into the fermenter. Mainly because I re-use my yeast several times and the more trub, the more work it is to get everything out.

For some reason my last two batches had an incredible amount of trub in the fermenter, and I don't know why. I've done 3 or 4 BIAB brews, no chill, and the first two had a lot less trub in the fermenter. The last two though, a lot. A thick layer, almost 2l worth in the bottom of the fermenter, and I would like to reduce/eliminate that.

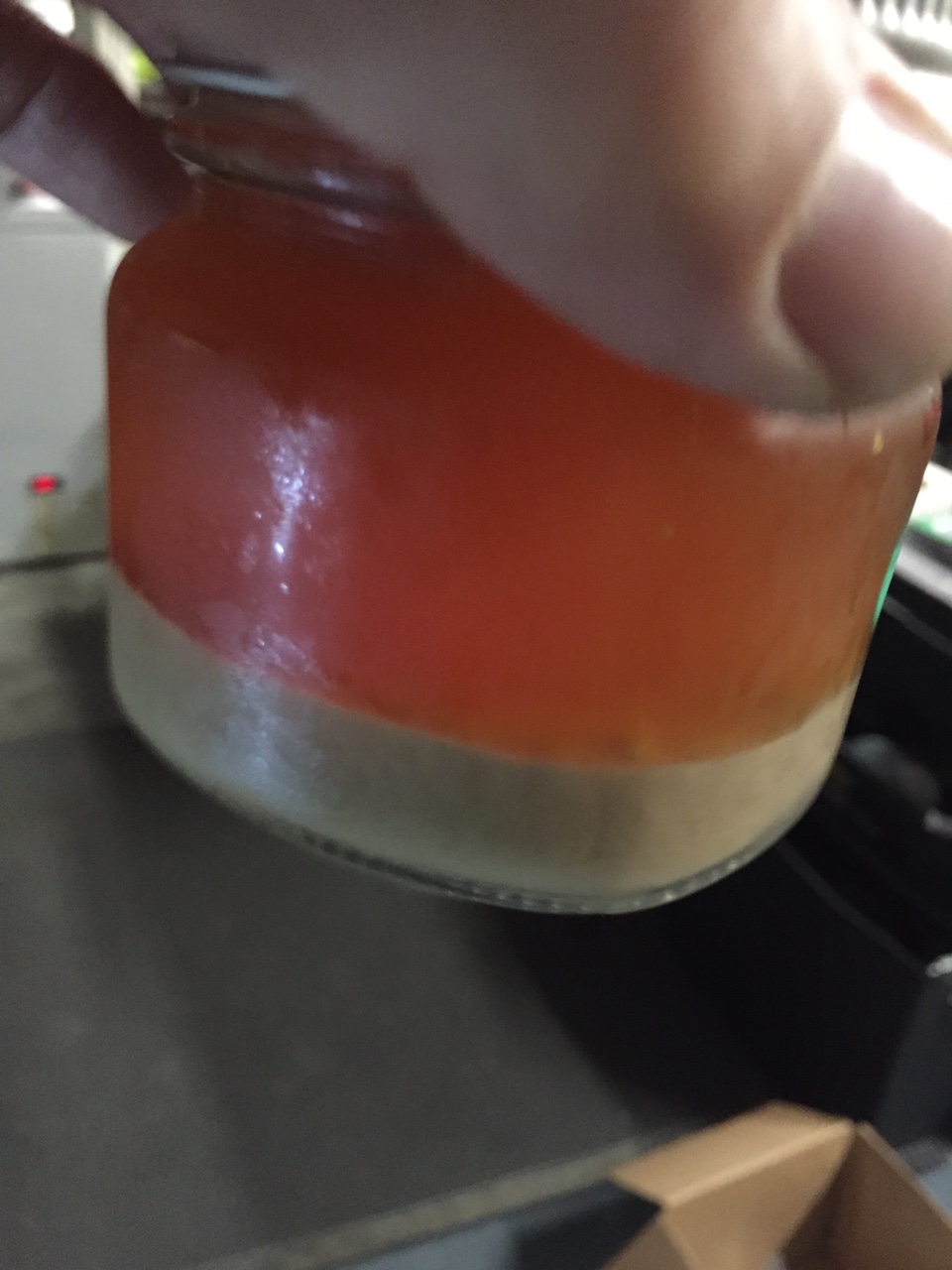

I have started using Irish Moss in the boil, but it seems like it's useless unless you chill. I'm in the process of building a chiller (but it's damn expensive, so it's going slow) so I was wondering - will that help?

Also, I have strongly considered racking the wort off into a no-chill cube, fining the wort with gelatin and letting that sit in the fridge for a few days before pouring it out into the fermenter. Yes, it's slower, but that should work, right? I'm not too bothered about clear beers in the bottle or glass, as gelatin works wonders there anyway, but I would really love to get a cleaner yeast cake out of each brew, so I'm open to suggestions and tips and tricks!

PS: I have done research on this and some topics are...dodgy. Including letting the wort cool down and then filtering over all kinds of filters and and and but that sounds like a risk of infection to me, when described the way they are.

I'm fairly new to AG (after coming from kits) and doing BIAB, and to be honest there's really just one thing that's really bothering me with this process - trub. I don't mind it in the kettle, I don't mind it in the mash, but man, it annoys the living daylights out of me when it gets into the fermenter. Mainly because I re-use my yeast several times and the more trub, the more work it is to get everything out.

For some reason my last two batches had an incredible amount of trub in the fermenter, and I don't know why. I've done 3 or 4 BIAB brews, no chill, and the first two had a lot less trub in the fermenter. The last two though, a lot. A thick layer, almost 2l worth in the bottom of the fermenter, and I would like to reduce/eliminate that.

I have started using Irish Moss in the boil, but it seems like it's useless unless you chill. I'm in the process of building a chiller (but it's damn expensive, so it's going slow) so I was wondering - will that help?

Also, I have strongly considered racking the wort off into a no-chill cube, fining the wort with gelatin and letting that sit in the fridge for a few days before pouring it out into the fermenter. Yes, it's slower, but that should work, right? I'm not too bothered about clear beers in the bottle or glass, as gelatin works wonders there anyway, but I would really love to get a cleaner yeast cake out of each brew, so I'm open to suggestions and tips and tricks!

PS: I have done research on this and some topics are...dodgy. Including letting the wort cool down and then filtering over all kinds of filters and and and but that sounds like a risk of infection to me, when described the way they are.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)