broncosaurs

Well-Known Member

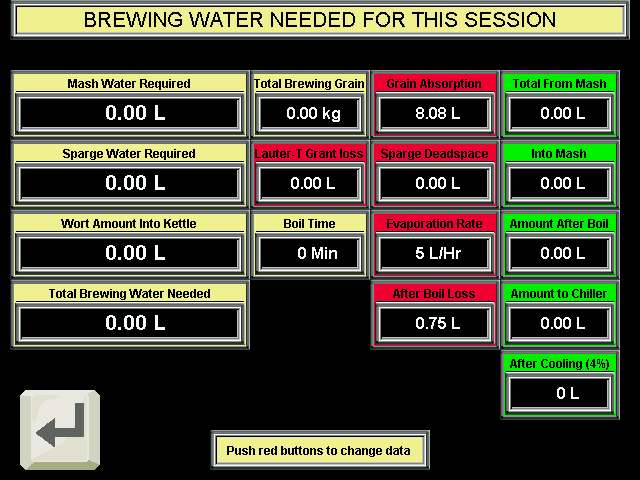

Saw a few starts on PLC touch control but looks as if nothing ever came of them. I just finished changing from gas to an all electric system using temperature controllers (PIDs as beer brew people call them). Being I love to tinker I thought I needed another controler. I started a 6 touch panel /PLC system. Touch screen is a black and white with 5 color white to red back ground. Screen is IP65 for wet hands and wash-down. Most all equipment is from Automation Direct. The system controls a HLT w/ 5500w heater, RIMs w/4000w heater (more on RIMs heater later), Mash Tun w/ 5500w heater and two pumps for liquid transfer and RIMs recirculation. System needs to run on a 30a 240v circuit. Im finishing up the programing now.

Cost so far is about $850. Missing enclosure($100-200) and one phase angle firing SSR ($15). Im sure I missed a few more items also.

As time permits Ill give more info for each part.

http://www.automationdirect.com/adc/Home/Home

Item Code Qty Short Description Price

EA1-S6MLW 1 TOUCH PANEL 6in STN 320x240 PIXEL 5 COLOR BG WHT/PINK 1, 2 & 3/RED $324.00 $324.00

DV-1000CBL 1 MICRO-GRAPHIC AND DV-1000 CABLE FOR AUTOMATIONDIRECT PLCS, 6 FT $19.00 $19.00

C0-01DD1-D 1 MICRO PLC, 8 DC IN / 6 SINK DC OUT, W/ RETENTIVE MEMORY, REQ 24VDC POWER $99.00 $99.00

C0-01AC 1 1.3AMP AC SYSTEM POWER SUPPLY NO POWER BUDGET $39.00 $39.00

C0-04THM 1 4-CH THERMOCOUPLE INPUT 16-BIT FOR CLICK $149.00 $149.00

WMZS2B30 1 SUPPLEMENTARY PROTECTOR 2 POLE 30A B CURVE $18.00 $18.00

WMZS2B06 1 SUPPLEMENTARY PROTECTOR 2 POLE 6A B CURVE $18.00 $18.00

SC-E1-110VAC 1 CONTACTOR 32A, 110-120VAC COIL, 54mm $37.50 $37.50

GCX1251-120 1 SEL 22mm METAL RED N.O. 120V MNTND 2-POS INC-ILLUM $15.50 $15.50

AD-SSR625-DC-280A 2 SOLID ST RELAY 25A SPST VDC INPUT N.O. 24-280 VAC PANEL MOUNT $17.50 $35.00

RS4N-DE 1 CARD RELAY 5A SPST 4 RLYS 24VDC COIL $29.50 $29.50

70620FR 3 RECPT SGL 20A 250VAC 2-POLE 3-WIRE NEMA L6-20 LOCK BLK NYLON $11.50 $34.50

70620NP 3 PLUG 20A 250VAC 2-POLE 3-WIRE NEMA L6- 20 LOCK BLK/WHT NYLON $8.75 $26.25

THMJ-MPJ 4 T/C CONNECTOR TYPE J CONT TEMP 400F MINI FLAT PIN PANEL JACK 14AWG $5.00 $20.00

$864.25

Pict 1 &2 Old System

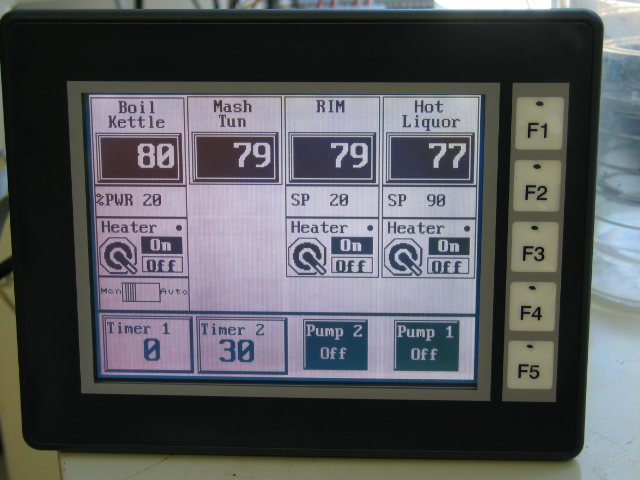

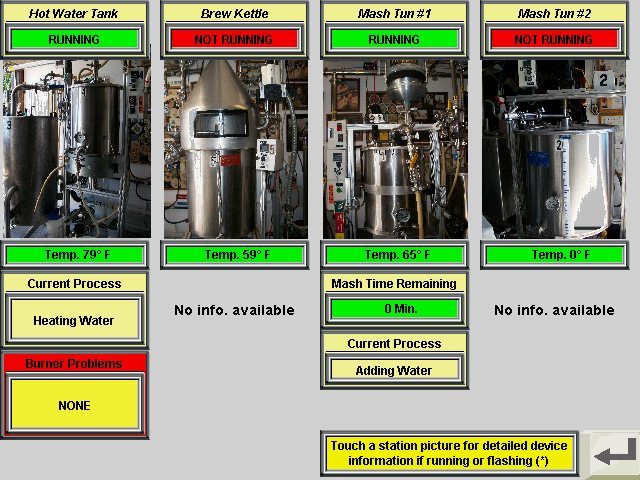

Pict 3 Touch Main Screen

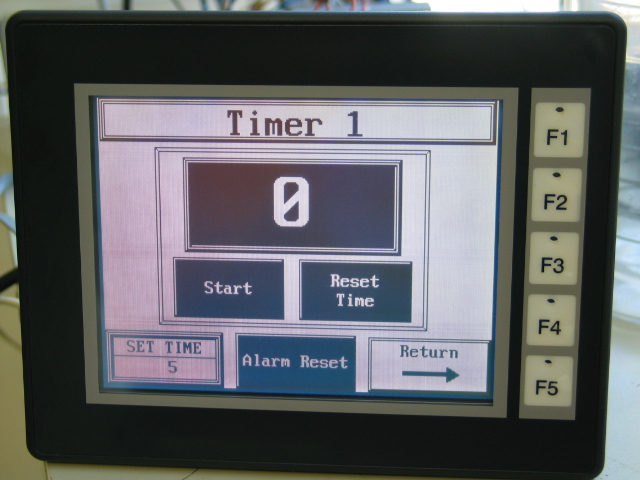

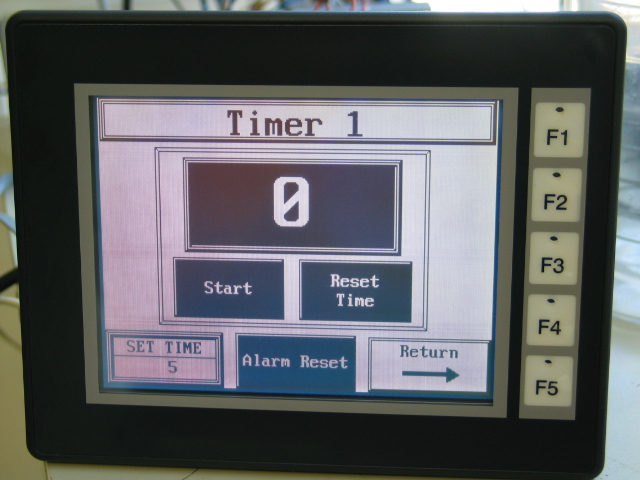

Pict 4 Touch 1 of two Timers

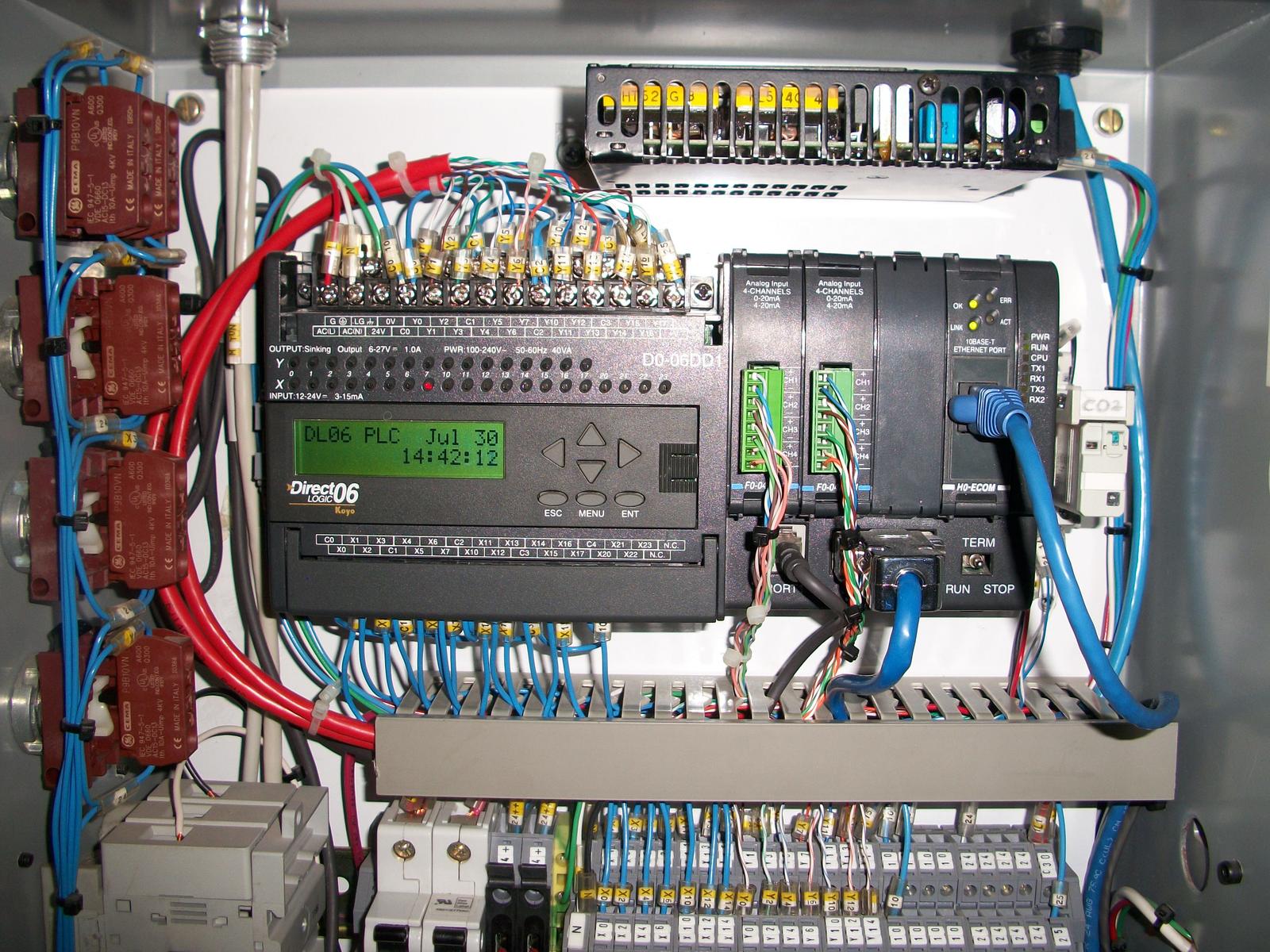

Pict 5 PLC w/ T/C inputs

Cost so far is about $850. Missing enclosure($100-200) and one phase angle firing SSR ($15). Im sure I missed a few more items also.

As time permits Ill give more info for each part.

http://www.automationdirect.com/adc/Home/Home

Item Code Qty Short Description Price

EA1-S6MLW 1 TOUCH PANEL 6in STN 320x240 PIXEL 5 COLOR BG WHT/PINK 1, 2 & 3/RED $324.00 $324.00

DV-1000CBL 1 MICRO-GRAPHIC AND DV-1000 CABLE FOR AUTOMATIONDIRECT PLCS, 6 FT $19.00 $19.00

C0-01DD1-D 1 MICRO PLC, 8 DC IN / 6 SINK DC OUT, W/ RETENTIVE MEMORY, REQ 24VDC POWER $99.00 $99.00

C0-01AC 1 1.3AMP AC SYSTEM POWER SUPPLY NO POWER BUDGET $39.00 $39.00

C0-04THM 1 4-CH THERMOCOUPLE INPUT 16-BIT FOR CLICK $149.00 $149.00

WMZS2B30 1 SUPPLEMENTARY PROTECTOR 2 POLE 30A B CURVE $18.00 $18.00

WMZS2B06 1 SUPPLEMENTARY PROTECTOR 2 POLE 6A B CURVE $18.00 $18.00

SC-E1-110VAC 1 CONTACTOR 32A, 110-120VAC COIL, 54mm $37.50 $37.50

GCX1251-120 1 SEL 22mm METAL RED N.O. 120V MNTND 2-POS INC-ILLUM $15.50 $15.50

AD-SSR625-DC-280A 2 SOLID ST RELAY 25A SPST VDC INPUT N.O. 24-280 VAC PANEL MOUNT $17.50 $35.00

RS4N-DE 1 CARD RELAY 5A SPST 4 RLYS 24VDC COIL $29.50 $29.50

70620FR 3 RECPT SGL 20A 250VAC 2-POLE 3-WIRE NEMA L6-20 LOCK BLK NYLON $11.50 $34.50

70620NP 3 PLUG 20A 250VAC 2-POLE 3-WIRE NEMA L6- 20 LOCK BLK/WHT NYLON $8.75 $26.25

THMJ-MPJ 4 T/C CONNECTOR TYPE J CONT TEMP 400F MINI FLAT PIN PANEL JACK 14AWG $5.00 $20.00

$864.25

Pict 1 &2 Old System

Pict 3 Touch Main Screen

Pict 4 Touch 1 of two Timers

Pict 5 PLC w/ T/C inputs

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)