Well as with many of us, a bit of life happened and it was not until a few weeks ago that I could finally brew on the new setup.

Brewed up a session blonde ale, and it was probably my smoothest brew day ever.

Roughly 16 minutes to go from 63F to 150F to mash in, and another 16 minutes to take it from 150F to boiling. Couldn't be more pleased with those times.

Only a few minor things.

My immersion chiller is fairly tall since I originally got it for this 15 gallon kettle to do both 5 and 10 gallon batches. Now it doesn't sit on the bottom, actually I had it sitting on my false bottom so it's not on the element. Most of it is really out of the wort now, not sure how i'm going to deal with that but I am really considering moving to a counterflow chiller. Chilling time was not horrible but much slower than it was before when it could sit on the bottom.

The elbow on my lid connection would not stop leaking so its a vertical connection for this brew, I have since remedied that and it connects at the proper angle again without the hose bending at an angle.

So happy to have gone electric!

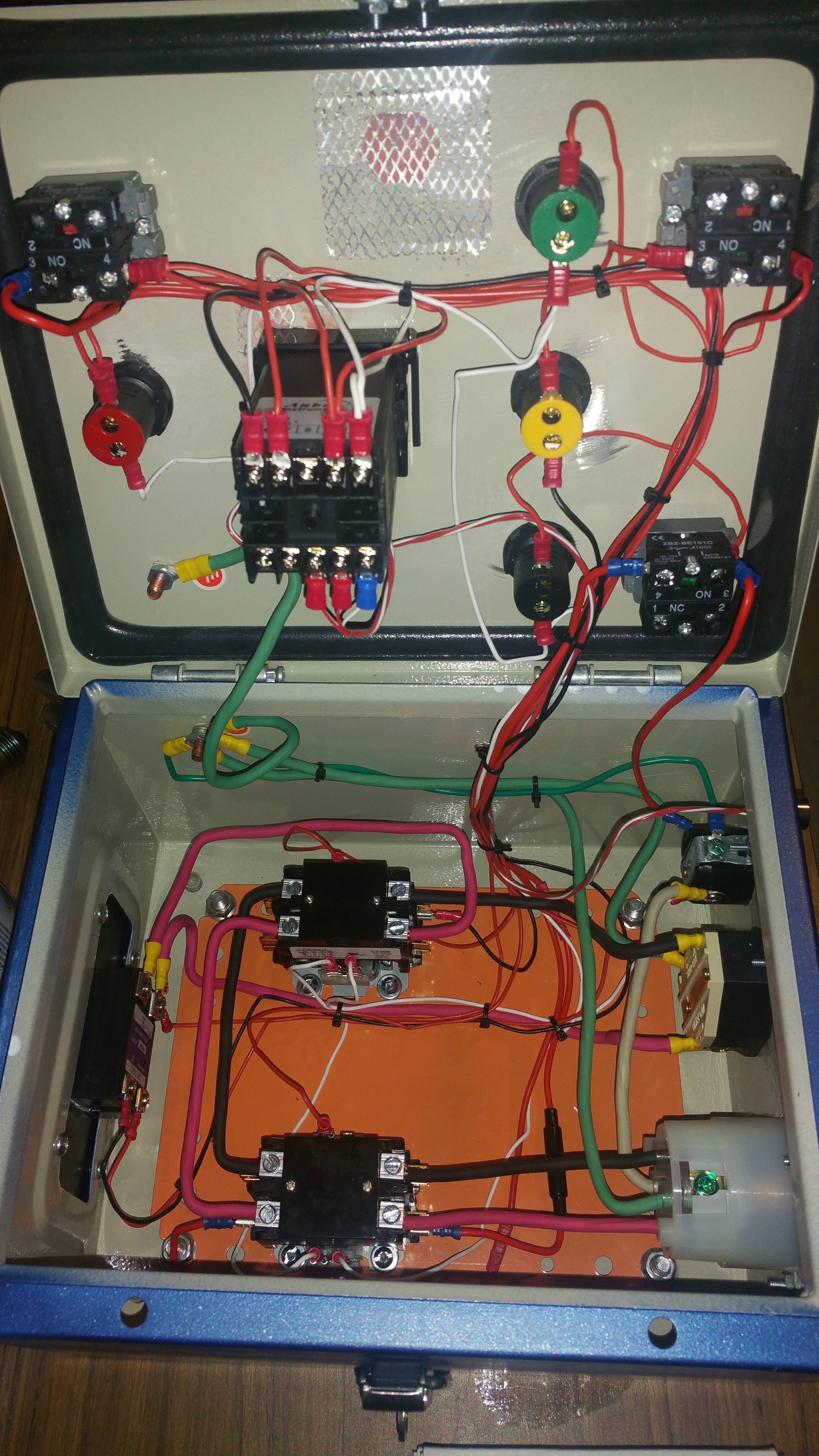

Just mashed in about to give a stir, put in the recirc attachment and close the lid.

System is so compact yet super powerful, I am very happy with my brew days.

Boil complete, just threw the chiller in about to shut off the elements and start chilling.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)