Finally it is happening.

I had started thinking about electric some time ago and first started a thread about trying to build it using a bottom drain keggle.

The more I got into the design I realized I should just drill my beautiful 15gallon ss brewtech pot and forget the keggle. Partially due to a great thread from @tofuguy here:

https://www.homebrewtalk.com/showthread.php?t=621165

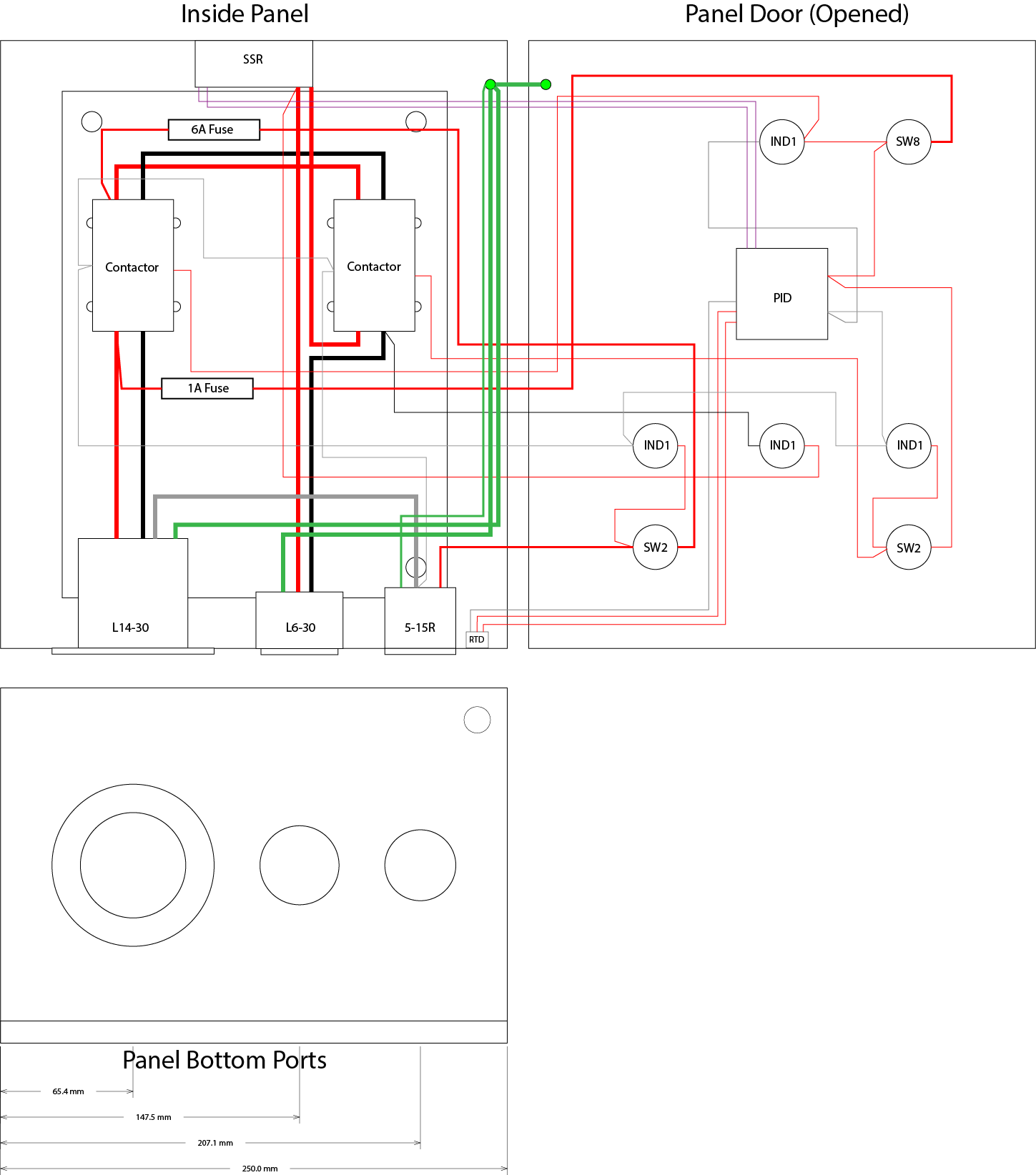

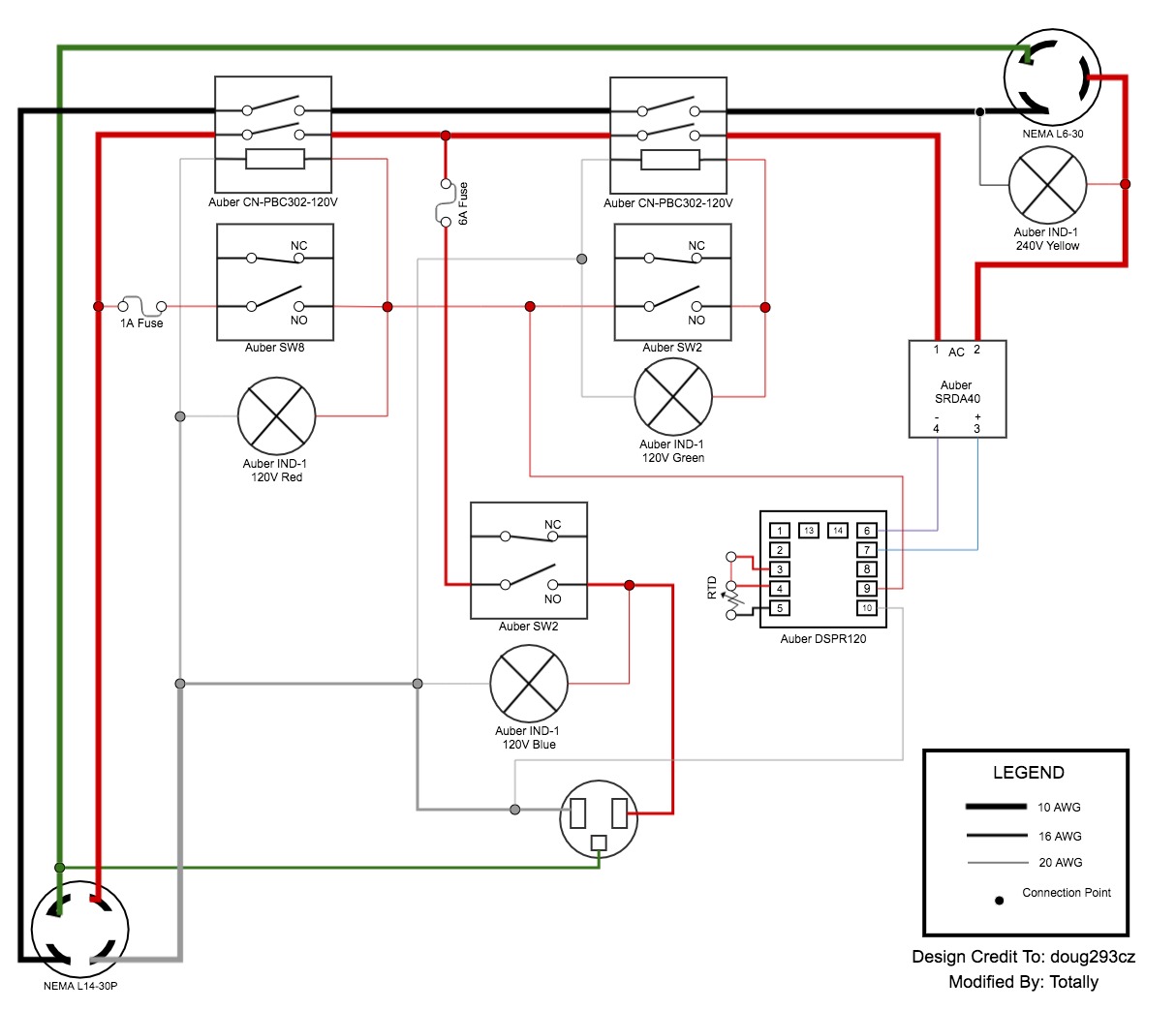

I had some great help from @doug293cz in my original thread about panel schematics as one would expect.

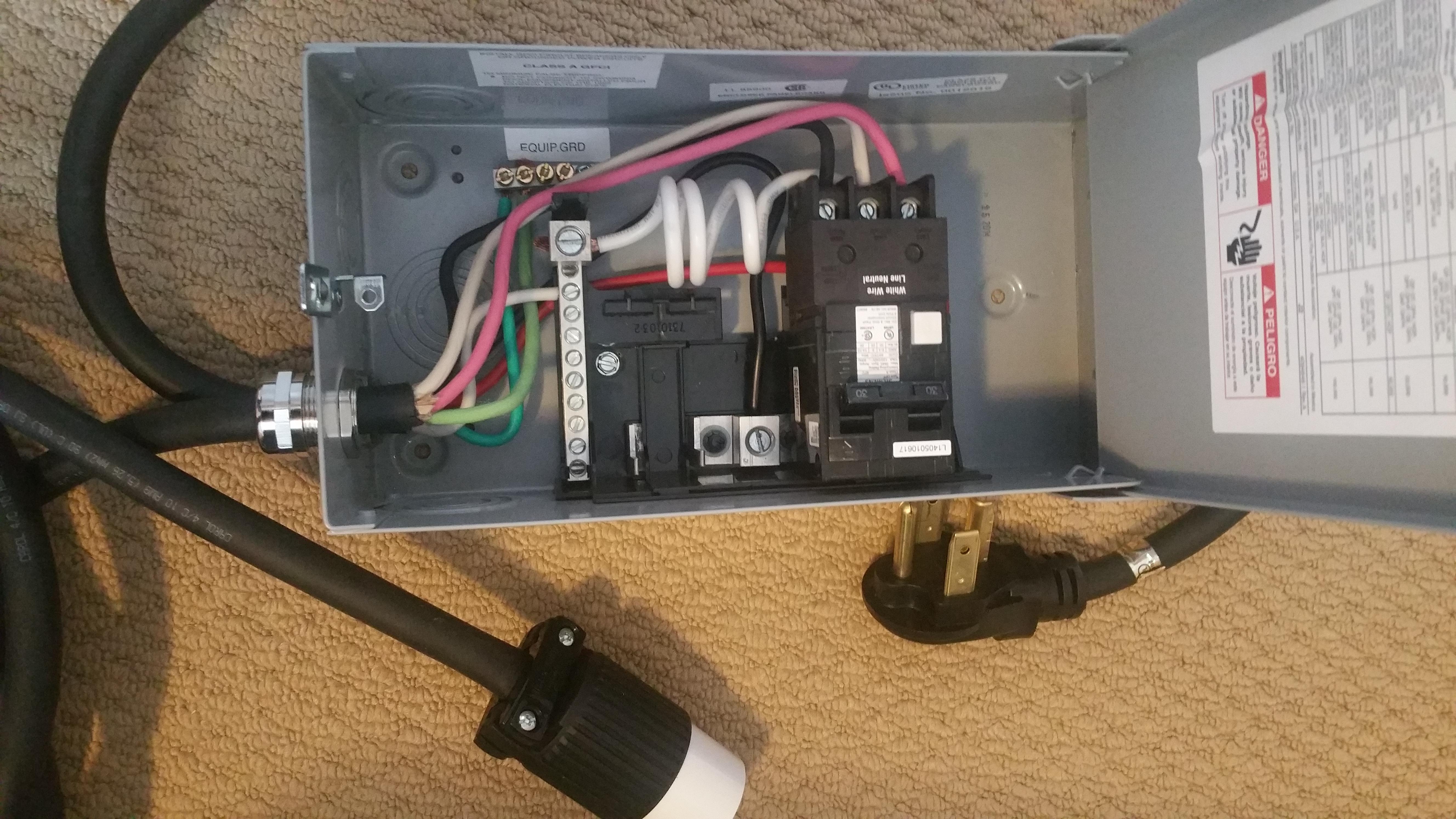

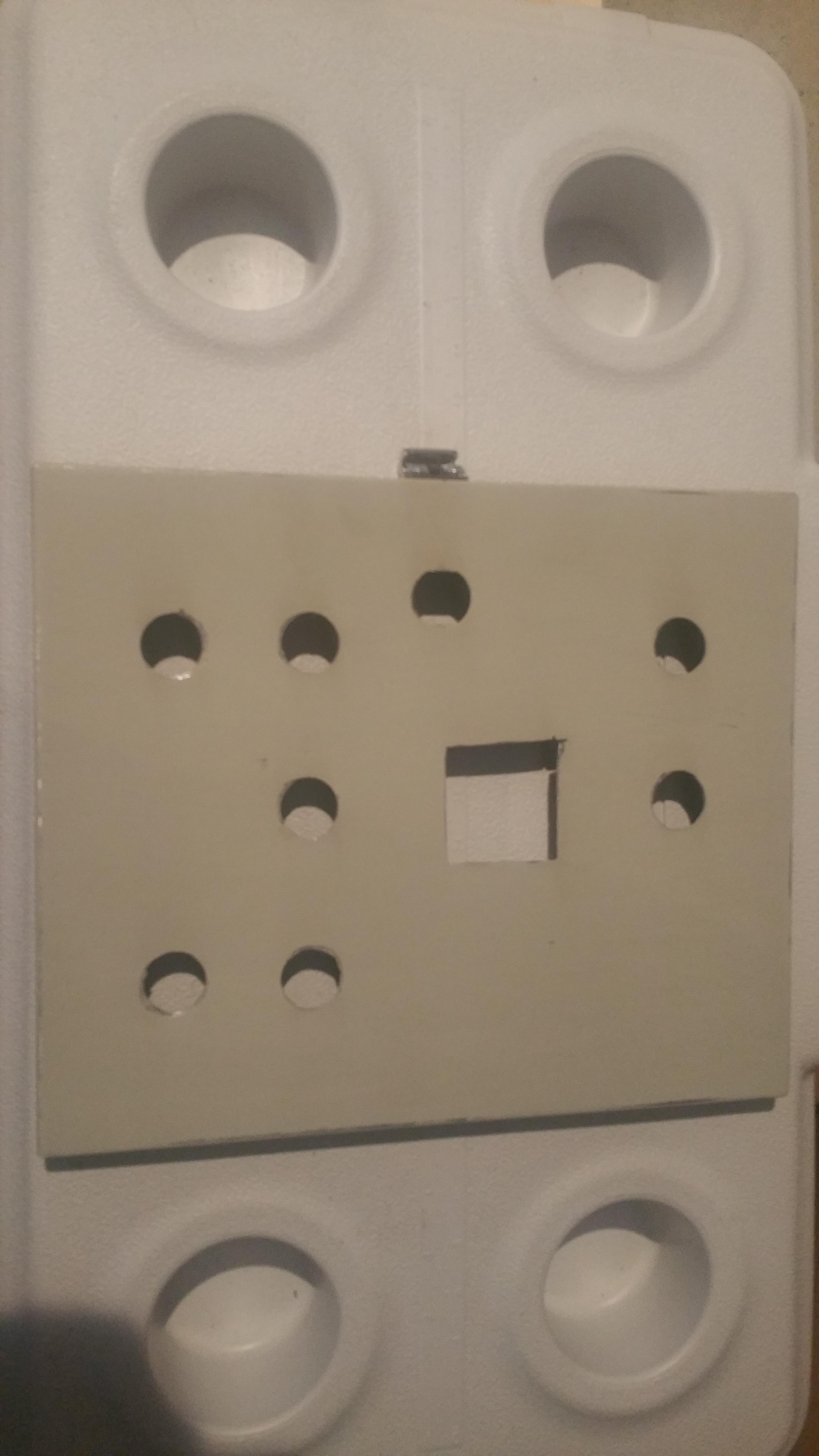

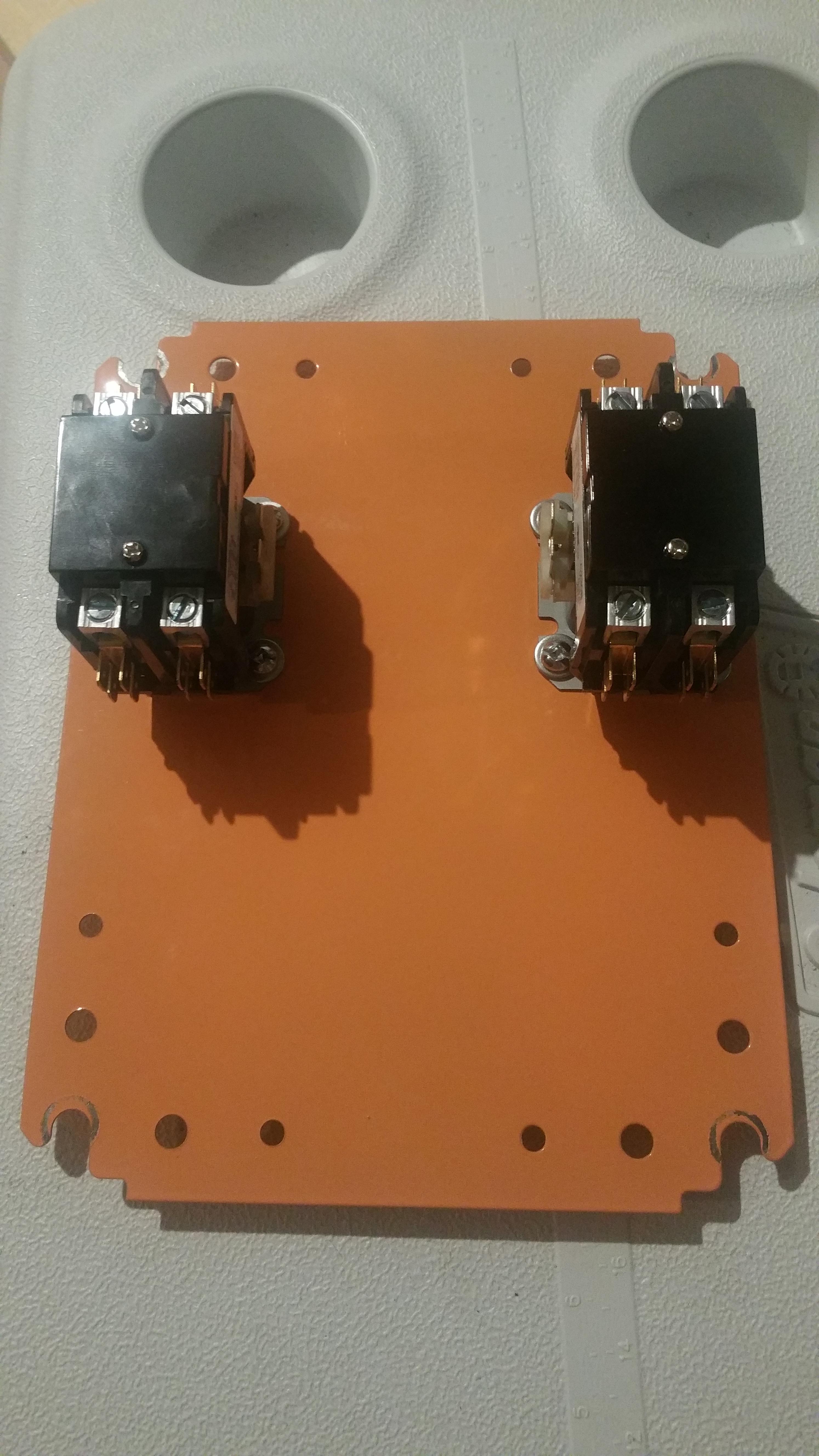

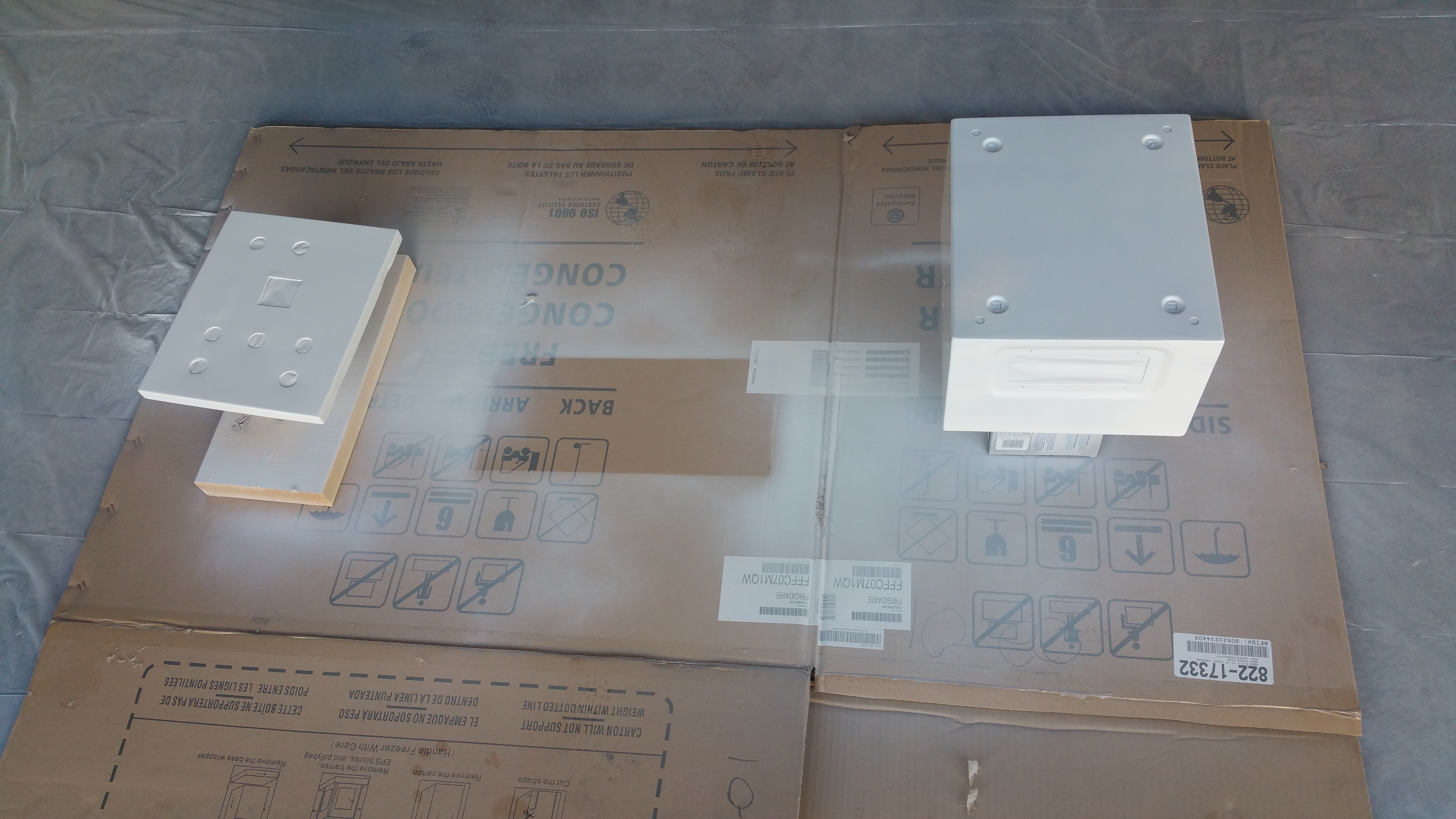

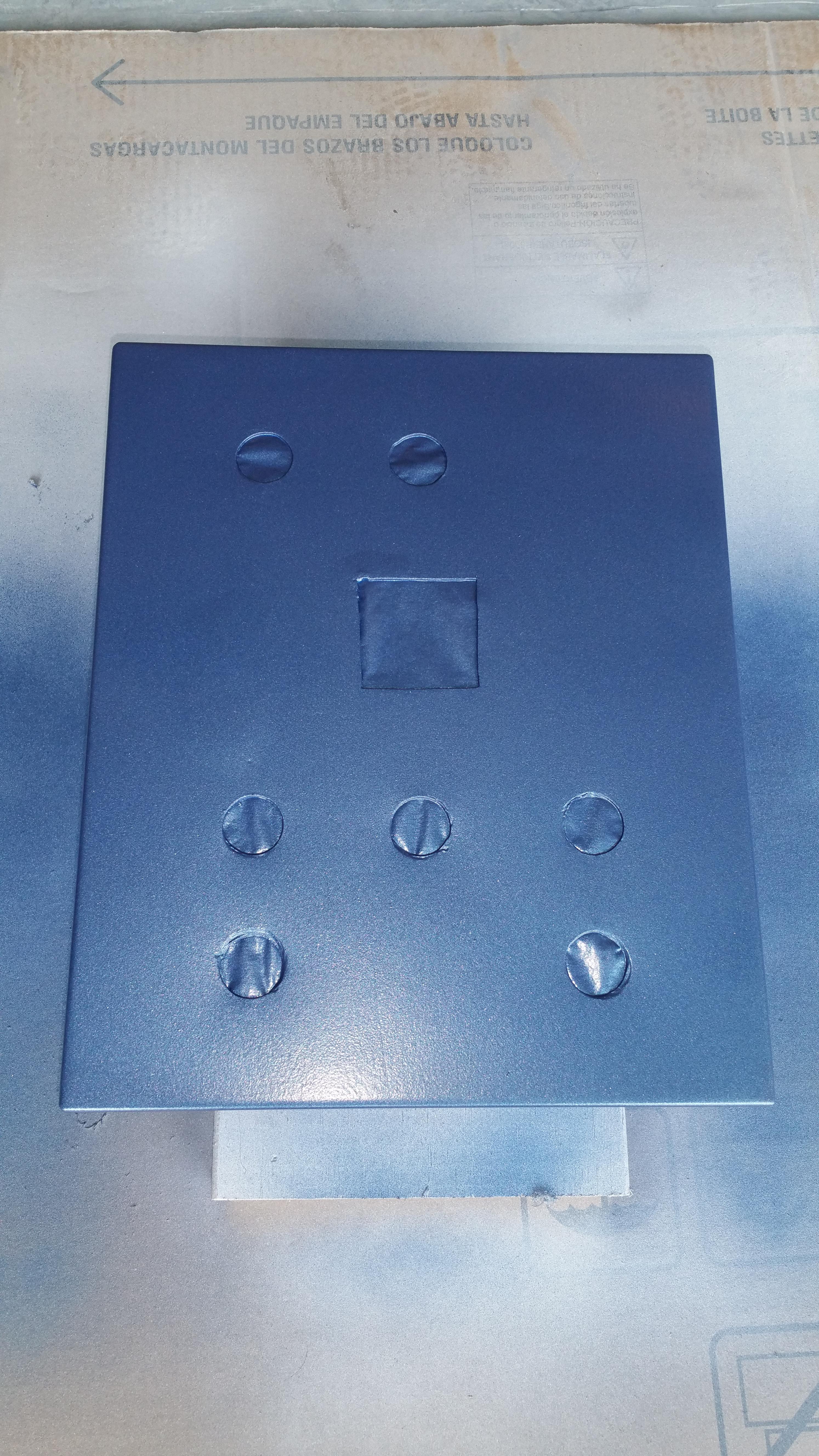

So I spent some time drawing things, making lists, learning and finally ordering up a ton of stuff from @Bobby_M , Auber and Amazon.

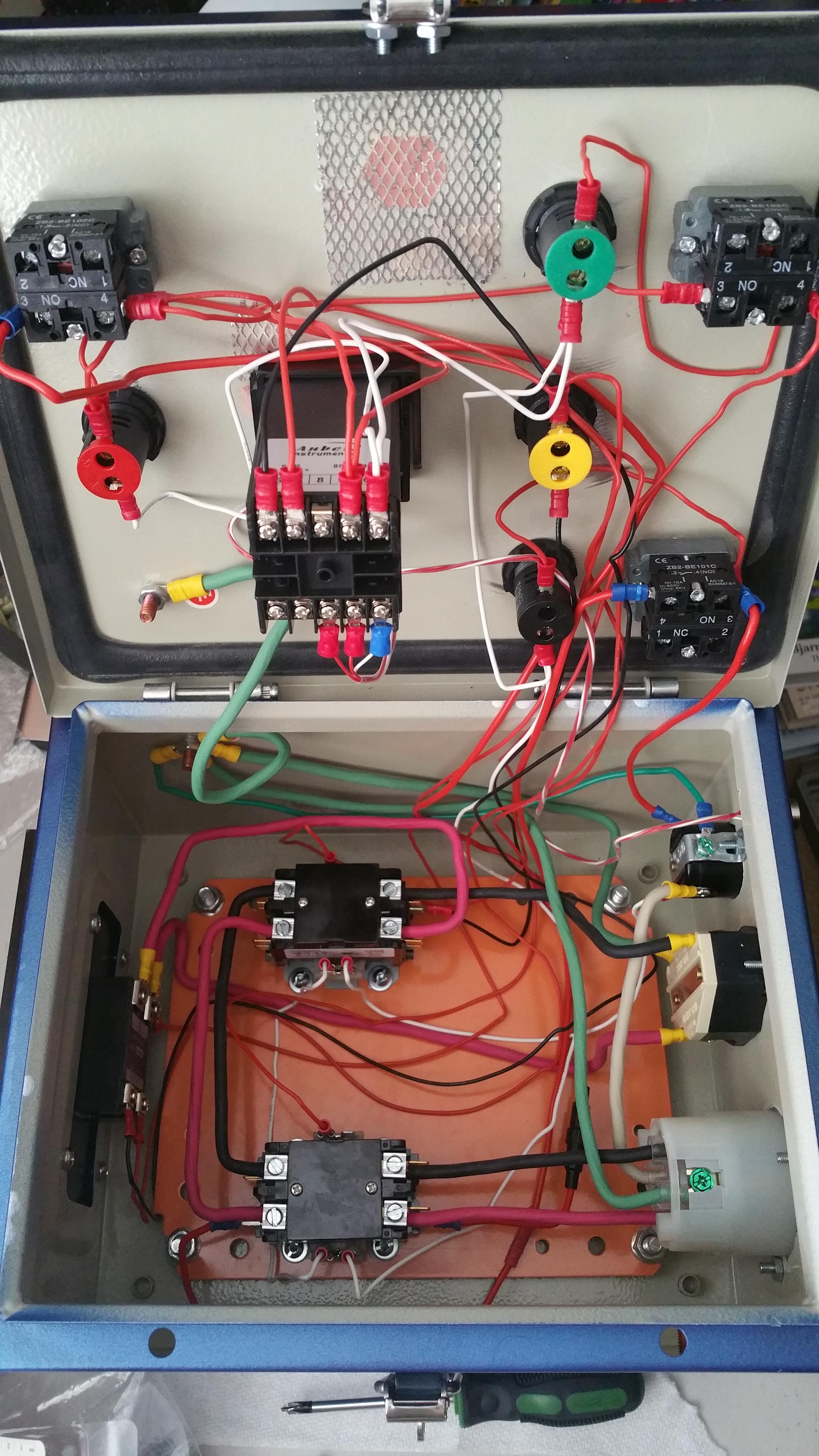

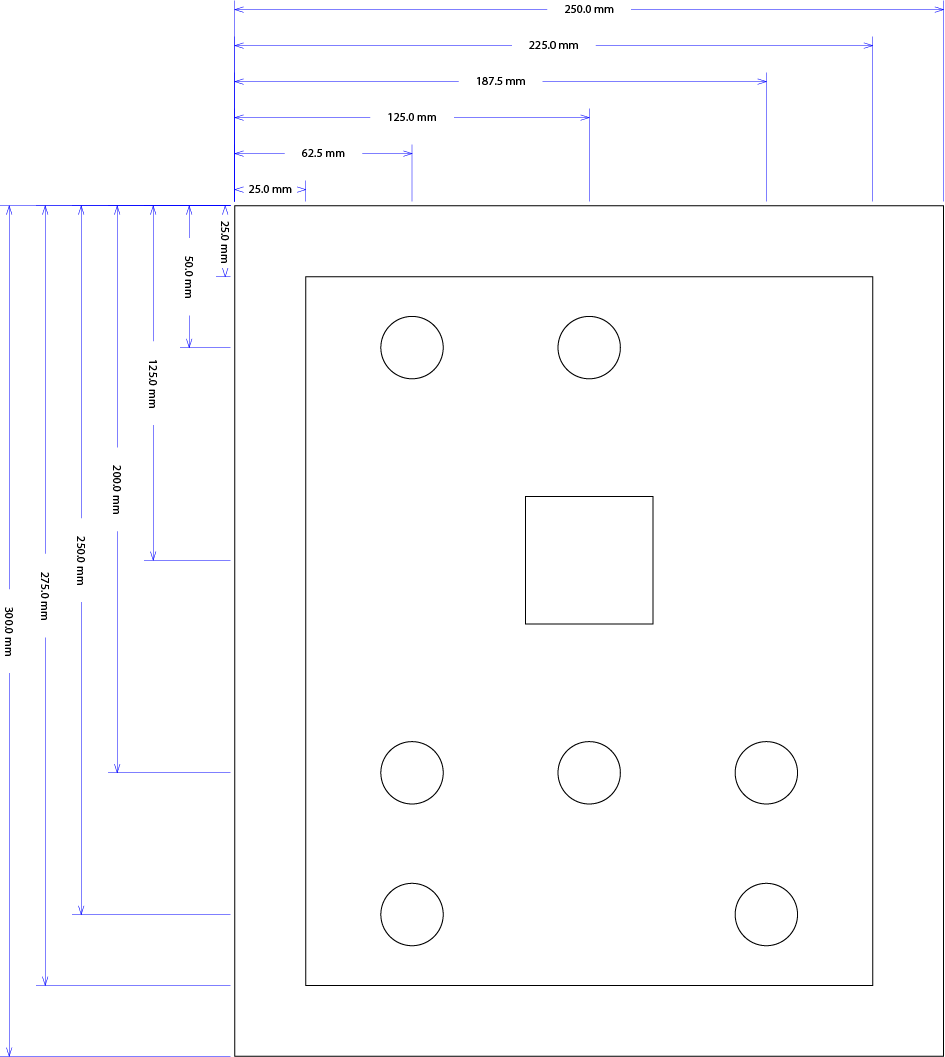

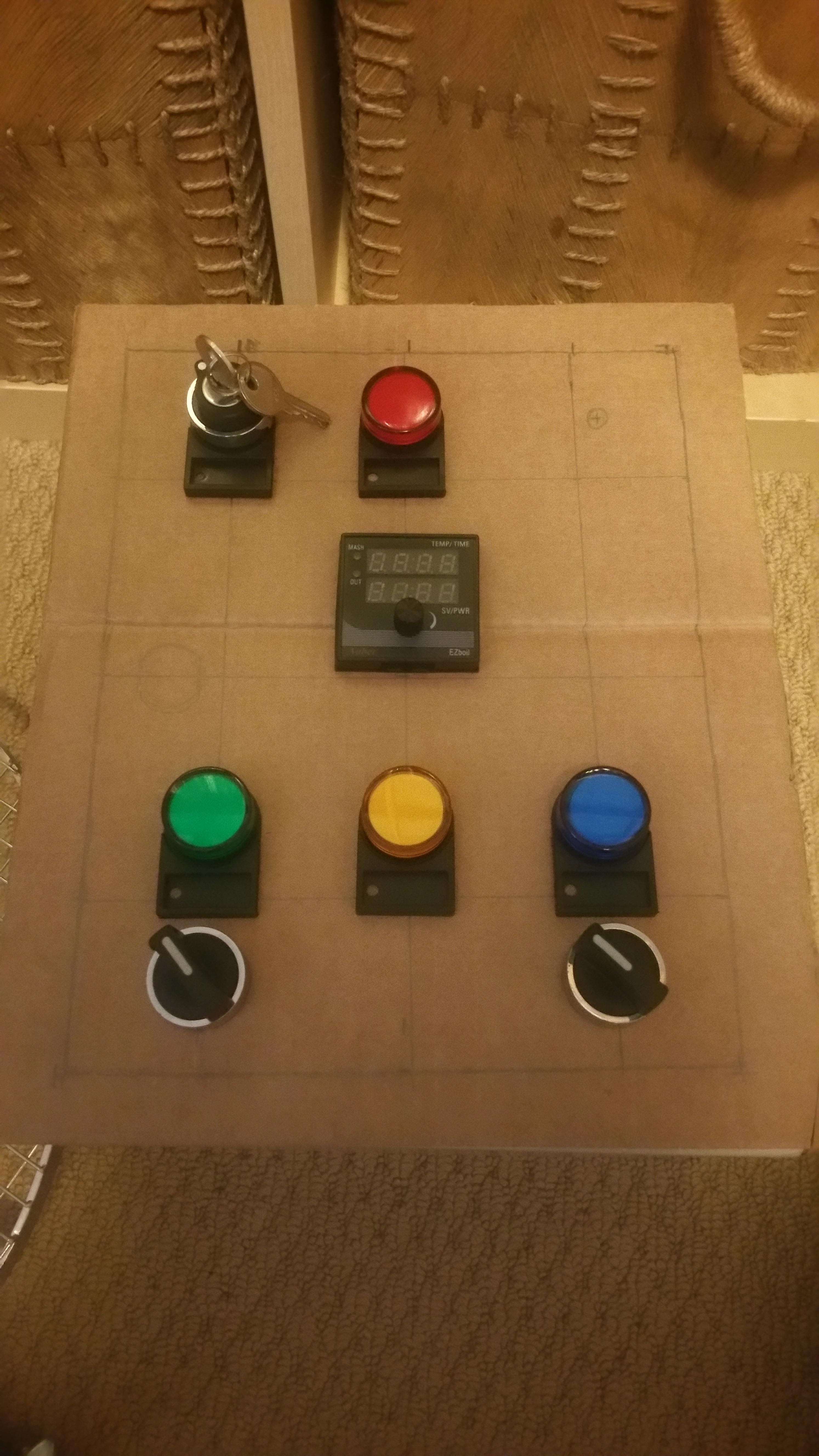

I will post some pics of where I am at currently and try to update things as the build progresses.

I had started thinking about electric some time ago and first started a thread about trying to build it using a bottom drain keggle.

The more I got into the design I realized I should just drill my beautiful 15gallon ss brewtech pot and forget the keggle. Partially due to a great thread from @tofuguy here:

https://www.homebrewtalk.com/showthread.php?t=621165

I had some great help from @doug293cz in my original thread about panel schematics as one would expect.

So I spent some time drawing things, making lists, learning and finally ordering up a ton of stuff from @Bobby_M , Auber and Amazon.

I will post some pics of where I am at currently and try to update things as the build progresses.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)