Goolsbymd

Well-Known Member

Tomorrow I'll be doing my first BIAB it is the lemon-lime hefe weiven by sd-slim

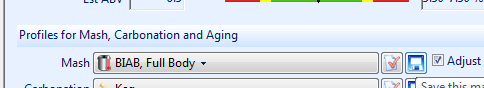

Grain bill is 11.25lbs. Using a paint strainer bag (going to double up until my wilser bag), wlp380 is on its stir plate already, beer smith is set up best i can and I am boiling 5 gallons of water to check boil off rate/hour to plug that into bs2. I'm shooting for 5 gallons, using a 15gallon SS concord kettle. According to beersmith I need to heat up initial water to 178, add grains (11.25lbs) for a target temp of 158 for 45 mins. Will secure fire, place lid on and wrap up to minimize thermal lose. After that's done mash out at 170 for 10 minutes. Is that 10 mins after the 45 mins or in my last 10 mins raise up to 170? Then proceed as usual for hop additions, cooling etc. everything look in order? No sparge, will squeeze. Looks like avg is .08/lbs for grain absorption so add an extra gallon.

I boil off approx 1.25gallons/hr.

So I'll start with 8.5g boil, -1.25 boil off, -.5 trub in ferm, -.5 from kettle hop trub, and -1 after squeezing grains.

Grain bill is 11.25lbs. Using a paint strainer bag (going to double up until my wilser bag), wlp380 is on its stir plate already, beer smith is set up best i can and I am boiling 5 gallons of water to check boil off rate/hour to plug that into bs2. I'm shooting for 5 gallons, using a 15gallon SS concord kettle. According to beersmith I need to heat up initial water to 178, add grains (11.25lbs) for a target temp of 158 for 45 mins. Will secure fire, place lid on and wrap up to minimize thermal lose. After that's done mash out at 170 for 10 minutes. Is that 10 mins after the 45 mins or in my last 10 mins raise up to 170? Then proceed as usual for hop additions, cooling etc. everything look in order? No sparge, will squeeze. Looks like avg is .08/lbs for grain absorption so add an extra gallon.

I boil off approx 1.25gallons/hr.

So I'll start with 8.5g boil, -1.25 boil off, -.5 trub in ferm, -.5 from kettle hop trub, and -1 after squeezing grains.