bracconiere

Jolly Alcoholic - In Remembrance 2023

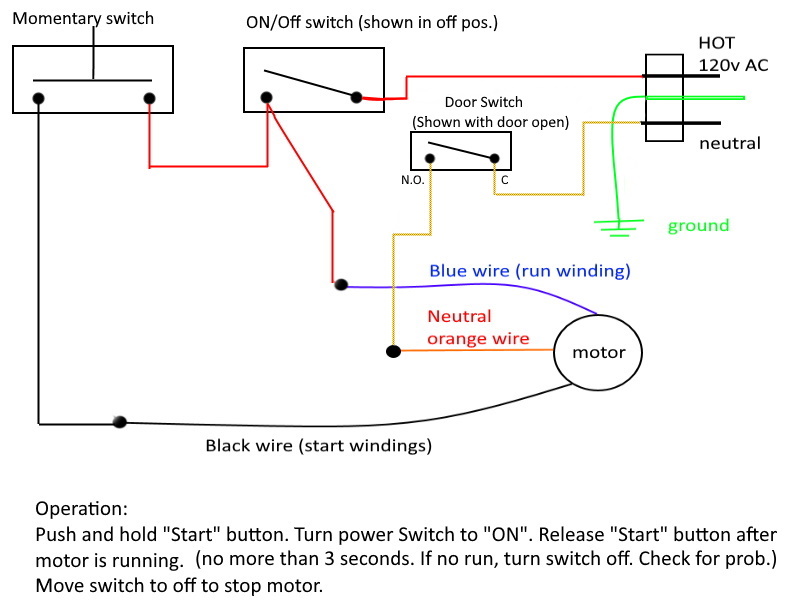

so Mom-on the dash just means mentary not that it stay on after a montary thing i take it....  do they even make a on-on-on ac toggle switch?

do they even make a on-on-on ac toggle switch?

Try thinking of it this way.

Would save your back at least.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

"separating the wheat from the chaff" so to speak has me wondering.

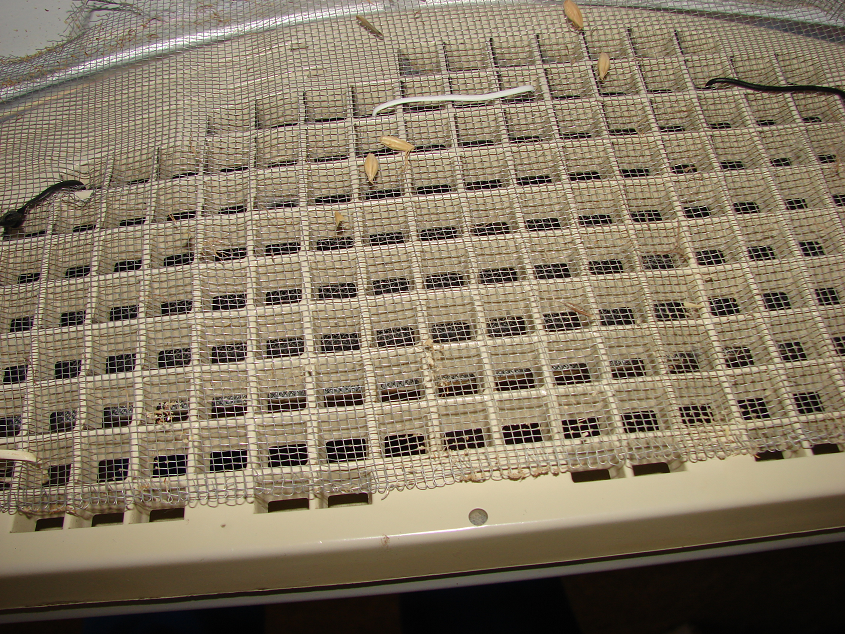

Cant wait for the next chapterall i have to do is put SS screen over the exit vent so the kernels don't go through it, let it run for 20-30 minutes...and it gets 'sucked off' in this case i think my clothes dryer blows...but should still work...might have to stick a shop vac down the vent tube on the back to help finish sucking afterwards....

i'll probably be using it next week. i'll try to get a vid of it firing up to post....

!!

!!My thoughts exactly![...] you might have found them at a local Ace or Do It Best hdw store. Wire nuts too.

Everything is is fixable. That said, at some point it's not worth it value wise. Sometimes even ppl like me say "eff it" and scab anything that's good off of it and toss the carcass.fixable? or buy a new one?

Doesn't the drum have many 1/4"-3/8" holes in it? If so, kernels and rootlets will end up in the (outer) drum mantle?all i have to do is put SS screen over the exit vent so the kernels don't go through it,

My thoughts exactly!

Or electrical/electronics supplier.

Heck, a regular light switch would have done it in a pinch.

Doesn't the drum have many 1/4"-3/8" holes in it? If so, kernels and rootlets will end up in the (outer) drum mantle?

I was thinking you'd line the inside of the drum with a tighter screen to keep all the kernels and rootlets inside the drum.

Doesn't the drum have many 1/4"-3/8" holes in it? If so, kernels and rootlets will end up in the (outer) drum mantle?

I was thinking you'd line the inside of the drum with a tighter screen to keep all the kernels and rootlets inside the drum.

I gotta laugh,, dryers are known to eat socks, for ***** sakes ! Grain ain't got a chance!! Then again, where there is a will, there is a way. I'd still tape a pair of pantyhose on the outlet ducting (at least the first time and don't use your fish nets, won't do much good LOL) to save the grain that might get through.Doesn't the drum have many 1/4"-3/8" holes in it? If so, kernels and rootlets will end up in the drum mantle?

I was thinking you'd put a tighter screen inside the drum to keep all the kernels and rootlets inside the drum.

Hell might even do one of the other (6) kits I've been sitting on for a while tomorrow. I am just finding it hard to pick which one.

Hell might even do one of the other (6) kits I've been sitting on for a while tomorrow. I am just finding it hard to pick which one.

As someone who has no plans to do my own malting

)

)

Oh, by the way, and when you get to the point of making a concentrated wort (LME) from you home malt,

I guess the fan should be sucking the air in and probably wouldn't be tossing the grain "out" but it could. I was thinking more about the rotating drum catching a finger or sleeve and something less than pleasant happening.

Cheers,

Joel B.

But hey, thanks for the input. Any thoughts are welcome. Some times the trees are hard to see standing in the forest.

Use rechargeables...(i would have taken a picture, but although my pictures are better now, this damn POS camera goes through 2 AAs in about a week.....

I had a Kodak that was so hard on batteries and did as you suggest. I could take maybe 4 pics before the rechargeables died. And that was only if they had not set for very long off the charger. It would only work on their high amp hour bats. I had 2 kodaks that were like this and glad that they are gone.Use rechargeables...

Santa is coming, know it is difficult to be good , but the new phones take great photos. Wish and try, try hardI had a Kodak that was so hard on batteries and did as you suggest. I could take maybe 4 pics before the rechargeables died. And that was only if they had not set for very long off the charger. It would only work on their high amp hour bats. I had 2 kodaks that were like this and glad that they are gone.

I had a Kodak