4. Do I just heat water to 155 or so, add grains to bag, let it sit there for an hour, remove bag, then continue on? Or is there more to it?

Thanks.

Essentially, yes.

Here is one way to get started with smaller batches and in phases that make sense to me. This is the advice I wish I had received before I bought my monster 3v system. I have both going now and I think at this point I've used the 1 gallon batch BIAB method almost as much as the 3V 10 gal batch system. It's nice to brew in the house.

____________

Phase One:

BeerSmith (moble ap or PC version)

3 Gallon Kettle

BIAB bag to fit (if you scale up later, this is your hop bag)

Auto Syphon

Scale (tenth gram accuracy hops now, water additions later)

Refractometer

FG Hydrometer

5L wine bottle or equivalent (Capable of fermenting 1.25 gallons with headspace for krausen)

Airlock

(2) 2L flip-top growlers/bottles

Corn Sugar for priming, grain for recipe (pre-milled), hops for recipe

Starsan

PBW

Whirlfloc

*With this setup you can mash and boil 2-2.5 gallons of wort on your stovetop (need at least 1.25 gallons of boiled wort), chill the boiled wort in your sink, transfer wort and ferment in the wine bottle, then transfer to the growlers and prime for carbonation. You end up with 4L of finished beer in two growlers. Not to mention you can do this in your kitchen.

Phase Two:

Mini fridge (tall enough to fit your fermentation vessel with airlock)

Inkbird temp controller (2 stage)

Reptile heat-mat (or propagation heat-mat or whatever source of heat you want to use)

Second 5L wine bottle

Second airlock

Two more flip-top growlers

Maybe a cheap Corona grain mill, but buying pre-milled at this rate of consumption is totally fine

**Now you are set to control the temperature of your fermentation and double you production capacity. With a 2 week fermentation window and a 1 week bottle refermentation you could add a third set of fermenter/airlock/growlers and set yourself up with 2 growlers per week with weekly brew days, and you can make a wide range of styles and not have to worry about what youll do with 5 gallons of Russian Imperial Death Water. Not to mention that if a recipe does go awry, you can dump and not lose much in the way of cost.

Phase Three:

RO water (purchased or produced with a home system)

Download Brewn Water (and read all the notes)

pH meter

pH meter calibration/storage solutions

Pipette

Lactic Acid (go EASY on additions here

start with half what is specified in Brewn, measure and adjust further)

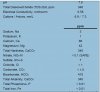

All chemicals for water adjustment listed in Brewn Water (Gypsum, Calcium Chloride, Baking Soda, etc.)

***Now you are not only controlling the temperature of your ferment, but you are also in control of your water profile. It can be tailored to support certain styles and their characteristics.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)