- Joined

- Nov 26, 2013

- Messages

- 9,936

- Reaction score

- 24,134

Never mind.

Problem exists between keyboard and chair.

Problem exists between keyboard and chair.

Last edited:

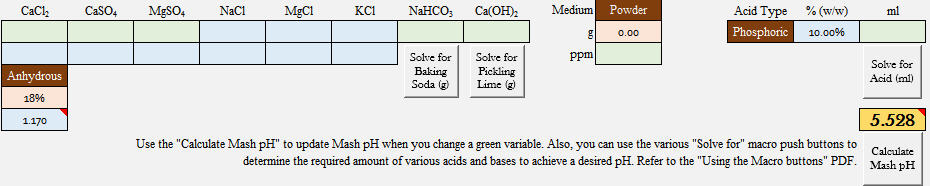

Calc Mash button works to show changes with grist and salts

Enter 5.4 and Calc Acid, leaves it zero.

Up Sourmaltz so that Calc Mash shows < 5.4 and Calc Soda/Lime leave those as zero

Excel 2016, Win7/64; Solver addin, trust macro and tools/ref Solver in VBA

Nothing you did wrong. I forgot to change the references in the VBA for the ML version. Should be good now.

In M vers, cell X46 is "=SUM($X$28:$X$36)" I think you mean =SUM($X$37:$X$45)

I just changed the spreadsheet refs, and the VBA functions , $X$something to $X$46 in the baksod/lime/ph functions and got it all sorted.

The Equation in Column J, Rows 5 through 13 should be updated to divide by K14.

No problem! I guess I have a silly question. Where did the information come from to populate the malt class database?

Does the Water Engine take into account the pH shift with Grist Ratio; in some instances I mash as low as 1 qt/lb or as high as 2.5 qt/lb?

Thanks for all you do on these spreadsheets, I still can't live without your brewing sheet. This is working great on my Mac I could never get your brewing engine lite you put out in November to work, but this one immediately worked. Quick question when I put the lactic acid at 1.7% which is what my Sauergut is at and I add 180ml, my mash PH is coming out at 3.269PH am I missing something or should I be entering the data differently.

Rodge, I thought I could cheat the system. Thanks again for everything you do here! I try to be a sponge to all your wisdom on this topic.You can’t model Sauergut as Lactic acid in this system.

I have not incorporated Sauergut yet.

Rodge, I thought I could cheat the system. Thanks again for everything you do here! I try to be a sponge to all your wisdom on this topic.

One other question, I'm still using Antioxin SBT should I add this in as Sodium and Powder?Two things:

1.) I prefer to thought of as a facilitator. This isn’t my work per se, i.e. the calcs are A.J. deLange’s and all of the malt titration info is not mine. If I can take credit for anything it’s that I have a very distinctive formatting style for spreadsheets. That’s it really. None of the hard work is mine.

2.) Use 60 ml/kg of malt of Sauergut in the mash per 0.1 pH drop desired. I’ll try and get the Sauergut working in there by tomorrow.

One other question, I'm still using Antioxin SBT should I add this in as Sodium and Powder?

Everything seems to be working for me now and I'm excited to give it a test this weekend. It is calling for significantly more lactic acid than I would normally use based on Bru'n water. 12 mL instead of 0 for this 15 gallon recipe.

I'm wishing you had option to use source water for sparge instead of assumption that I'm using RO for sparge. My source water is pretty soft so I've never bothered getting into RO. But without that toggle I don't see how to figure out my finished water profile...this is important to me for understanding salt impact on flavor. I suppose I might be able to figure out some set of salts that would turn RO water into my base water and then add those to the kettle addition. Off to try that now...

Understood. The only reason why I ask is that I ran into a situation where my Breiss Brewers Malt ended up having a DI pH of 5.4 which is significantly different than the DI pH referred to in The Water Engine and MME. I understand every maltster is different.

As we discussed already, it would benefit the brewing community to have a database (or a thread) that tracked the data individual brewers are seeing (e.g., maltster, malt type, DI pH, a1, a2, and a3) and include the literature data.

Does the Water Engine take into account the pH shift with Grist Ratio; in some instances I mash as low as 1 qt/lb or as high as 2.5 qt/lb?

The spreadsheet is solid. I appreciate all your hard work.

Everything seems to be working for me now and I'm excited to give it a test this weekend. It is calling for significantly more lactic acid than I would normally use based on Bru'n water. 12 mL instead of 0 for this 15 gallon recipe.

I'm wishing you had option to use source water for sparge instead of assumption that I'm using RO for sparge. My source water is pretty soft so I've never bothered getting into RO. But without that toggle I don't see how to figure out my finished water profile...this is important to me for understanding salt impact on flavor. I suppose I might be able to figure out some set of salts that would turn RO water into my base water and then add those to the kettle addition. Off to try that now...

One other question, I'm still using Antioxin SBT should I add this in as Sodium and Powder?

Sweet, Thanks!SBT is now back in for v1.03. Still working on Sauergut.

Can you identify the version number within the Spreadsheet in addition to the file name? Maybe even keep track of the revision history in another tab of the file. I often change the file name to my recipe name and date brewed which will remove the version number in the file name.

@RPIScotty I was able to do a side by side comparison today of your Water Engine and my ezRecipe 2.01 calculations. Here is what I found.

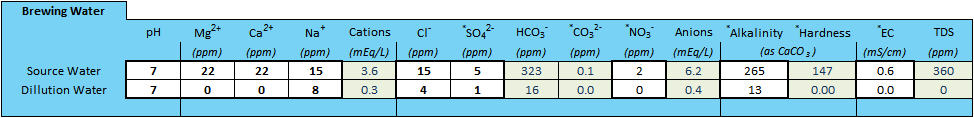

I started out using my RO water profile as 100% of the (12 gallons/45.43 liters) of strike water.

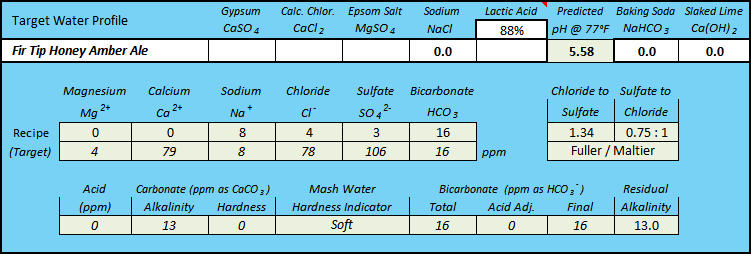

View attachment 610350

The mash pH prediction using the Briess grains below is 5.66 using the Water Engine DIpH override values.

(pH prediction method based on Kai Troester 2012)

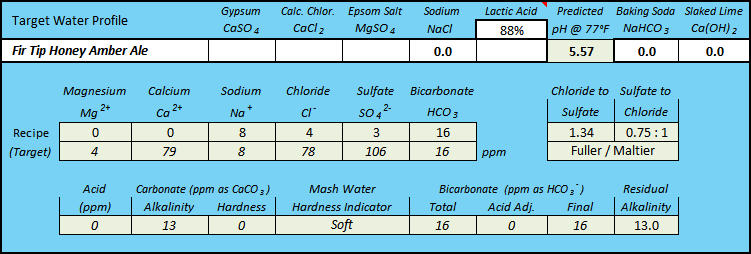

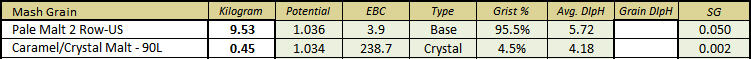

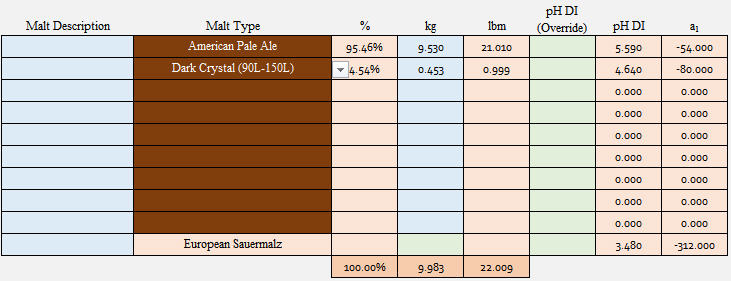

View attachment 610340

View attachment 610342

The mash pH prediction using the Briess grains below is 5.67 using the Riffe formula.

(pH prediction method based on Kai Troester 2012)

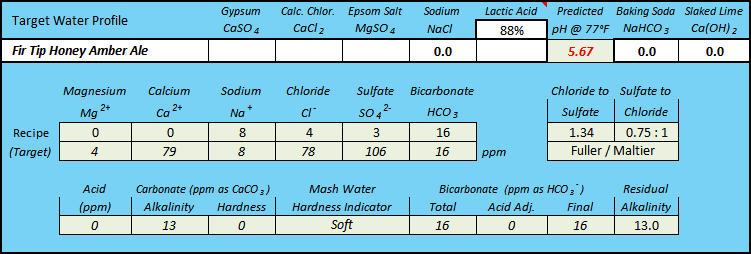

View attachment 610345

View attachment 610346

The mash pH prediction using the same Briess grains is 5.58 using color-based formula.

(pH prediction method based on Kai Troester 2009)

View attachment 610343

The mash pH prediction entering the same type of grains in Water Engine is 5.62 using the Gen II formula.

View attachment 610347

View attachment 610348

A nice new feature of ezRecipe 2.01 lets me select between 3 different pH mash prediction methods. Making these comparisons easy to do.

After replacing Flaked Wheat/Rye with Dark Crystal malt type for the Crystal 90L in my recipe as I wish I did in the first place the Water Engine predicted a mash pH of 5.53. So then I went back and corrected my original post to show the new results.That wheat/rye DI pH in my sheet looks suspect. 6.61 has to be an error.