You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Testing fermentability of crystal malt

- Thread starter nilo

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

OK, one last round before going on vacation.

Got the malt blended to a fine powder instead of milling it 3 times to check if that would improve the extraction since I was under the impression that I could get more sugars out of the malt.

Guess what happened?

I got a stuck mash, oh yeah

I had to add another 1/4# rice hulls and some more water to have it running.

But that was not the big surprise. The amount of sugars extracted was actually less than before, when I just milled the grain 3 times.

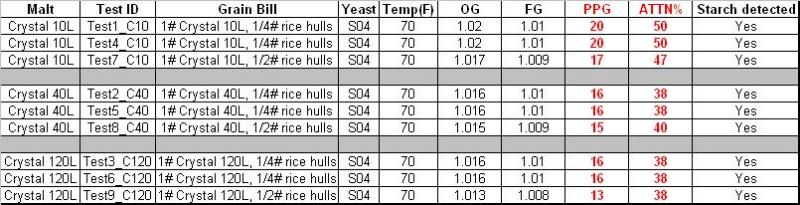

On my previous two test batches, if you remember, I got consistent 20 PPG for crystal 10 and 16 for crystal 40&120.

I got now 17 for C10, 15 for C40 and 13 for C120.

My preliminary conclusion is that the lautering process was impacted, weird I know, but I will stick with the previous milling process on future tests

Anyways, will report back the attenuation I get for this batch. I expect it to me the same than before.

Got the malt blended to a fine powder instead of milling it 3 times to check if that would improve the extraction since I was under the impression that I could get more sugars out of the malt.

Guess what happened?

I got a stuck mash, oh yeah

I had to add another 1/4# rice hulls and some more water to have it running.

But that was not the big surprise. The amount of sugars extracted was actually less than before, when I just milled the grain 3 times.

On my previous two test batches, if you remember, I got consistent 20 PPG for crystal 10 and 16 for crystal 40&120.

I got now 17 for C10, 15 for C40 and 13 for C120.

My preliminary conclusion is that the lautering process was impacted, weird I know, but I will stick with the previous milling process on future tests

Anyways, will report back the attenuation I get for this batch. I expect it to me the same than before.

Kaiser

Well-Known Member

The amount of sugars extracted was actually less than before,

Nilo,

Did you get a chance to test the gravity of the wort in the mash after mashing and before lautering?

Kai

Kai, I didn't and I'm confused. Do you mean to stir the mash before lautering and measure the gravity of the wort? if I just collect a sample from the mash tun from the spigot without stirring, that will mostly be a concentrated wort that sit on the bottom of the mash tun.

I’m trying to understand the formula you listed:

Extract potential = 100 * (Plato – R) / (100 – Plato)

Just for understanding the formula, let’s assume I stirred the mash and took a reading of 17 plato = 1.070. I used 0.75gals of water = 2.84l and 1lb of grains=0.453Kg.

Using the formula, the Extract Potential would be 13%. How do I get PPG from this value?

I’m trying to understand the formula you listed:

Extract potential = 100 * (Plato – R) / (100 – Plato)

Just for understanding the formula, let’s assume I stirred the mash and took a reading of 17 plato = 1.070. I used 0.75gals of water = 2.84l and 1lb of grains=0.453Kg.

Using the formula, the Extract Potential would be 13%. How do I get PPG from this value?

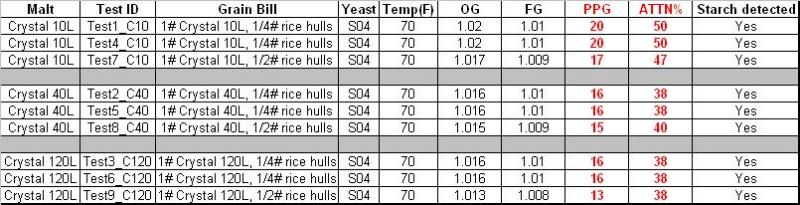

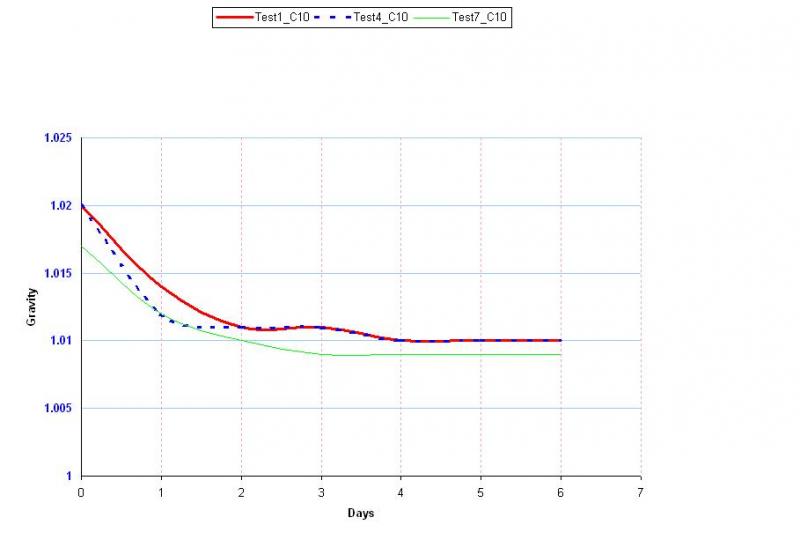

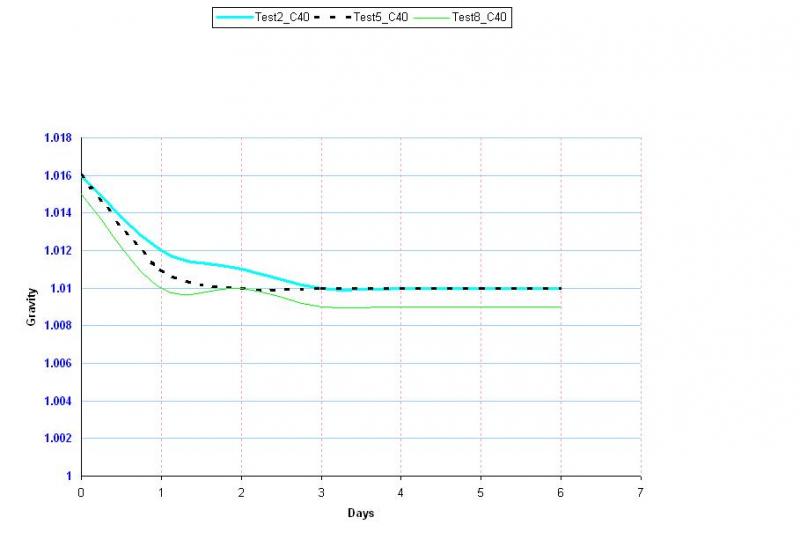

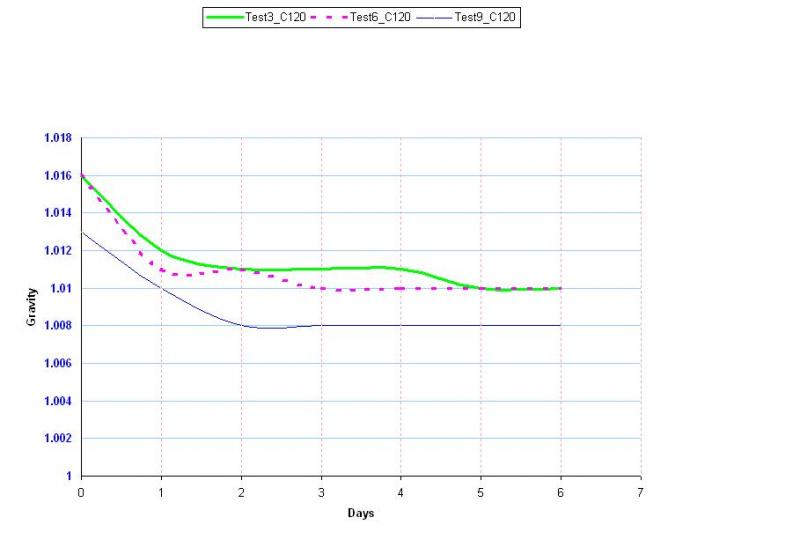

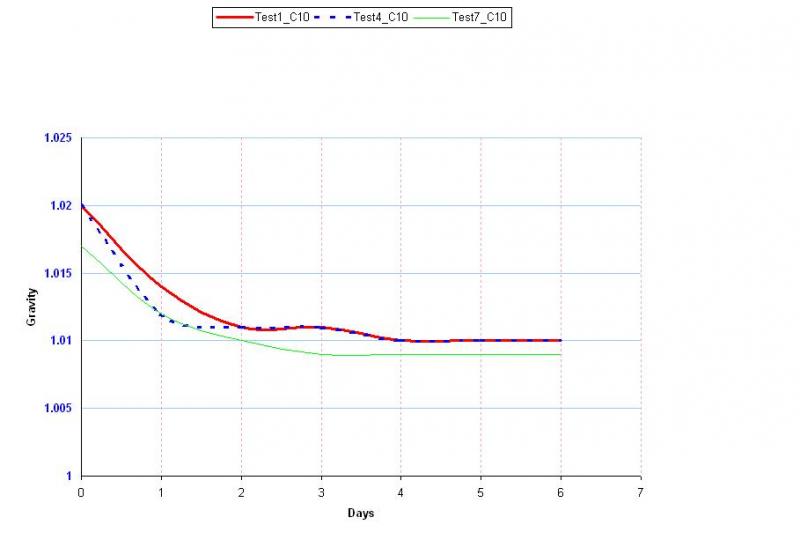

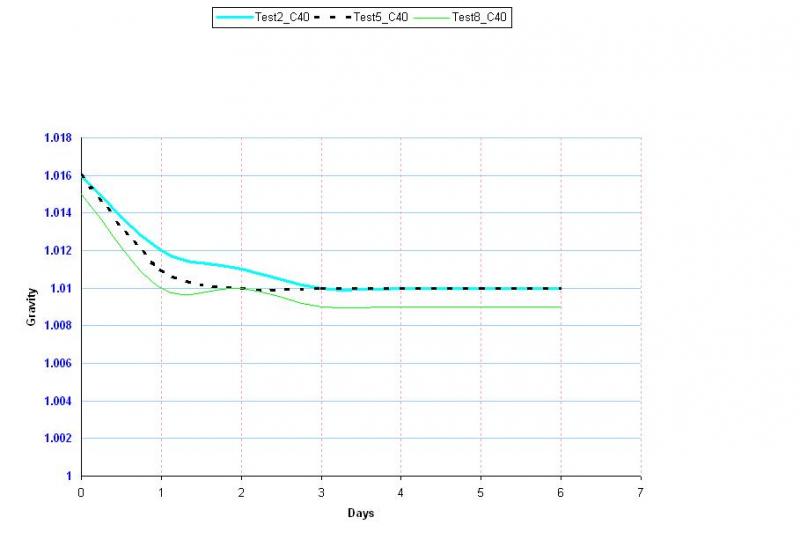

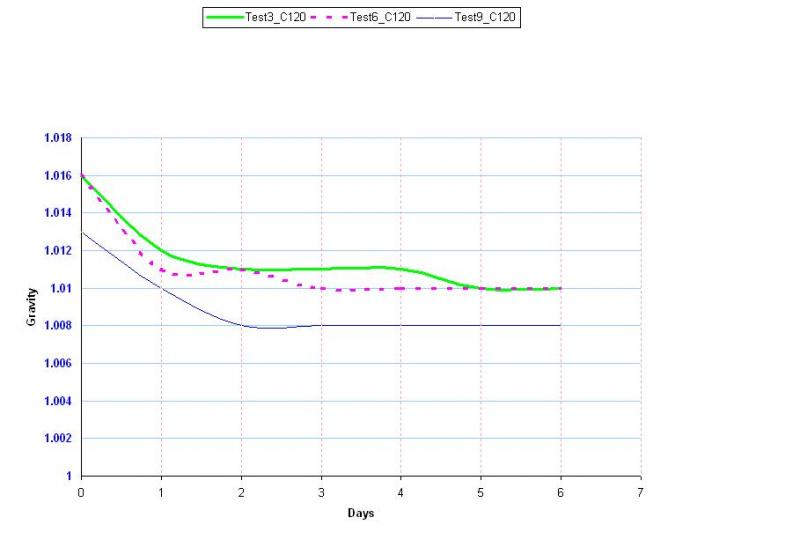

Here are the results for the 3rd round of testing.

Knowing I had issues with the extraction of last batch (still working with Kai on that), at least the attenuation has been very constant around 50% for Crystal 10 and 38% for Crystal 40 and 120.

Thank you guys for all feedback. I'm excited to continue with the next tests that will include testing with base malt only, then with a mix of 50/50 based malt and crystal.

Happy new years and will be back in few weeks.

Knowing I had issues with the extraction of last batch (still working with Kai on that), at least the attenuation has been very constant around 50% for Crystal 10 and 38% for Crystal 40 and 120.

Thank you guys for all feedback. I'm excited to continue with the next tests that will include testing with base malt only, then with a mix of 50/50 based malt and crystal.

Happy new years and will be back in few weeks.

Kaiser

Well-Known Member

Kai, I didn't and I'm confused. Do you mean to stir the mash before lautering and measure the gravity of the wort? if I just collect a sample from the mash tun from the spigot without stirring, that will mostly be a concentrated wort that sit on the bottom of the mash tun.

After the mashing is complete, stir up the wort and let the grain settle again. Then take a sample from the top or the spigot. There won't be much of a difference

Im trying to understand the formula you listed:

Extract potential = 100 * (Plato R) / (100 Plato)

Just for understanding the formula, lets assume I stirred the mash and took a reading of 17 plato = 1.070. I used 0.75gals of water = 2.84l and 1lb of grains=0.453Kg.

The formula I gave you is oncorrect. The correct formula is:

Extract potential = 100 * Plato * R / (100 Plato)

In your case this means

100 * 17 * 6.27 l/kg / (100 - 17) = 128%

Which is not possible. Either your mash thickness number or the first wort measurement is too high.

Using the formula, the Extract Potential would be 13%. How do I get PPG from this value?

To get the ppg number just multiply the extract percentage with 0.46.

Kai

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

Thanks, I got it. The 17 value was just a number I picked to test the formula. It was not measured.

I think the formula will result a valid max extraction IF you use the malt blended into powder, in order to make the milling process not a variable, agree?

I think the formula will result a valid max extraction IF you use the malt blended into powder, in order to make the milling process not a variable, agree?

Couldn't go on vacation before testing the extraction as suggested by Kai, so spent another 3lb of crystal malt to get it done.

Here are the results. Used malt blended to powder, 1 gal of water and 1lb of malt:

Crystal 10L, Plato=6.5, Extraction%=58, PPG=26

Crystal 40L, Plato=5.5, Extraction%=48, PPG=22

Crystal 120L, Plato=4.0, Extraction%=35%, PPG=16

Here are the results. Used malt blended to powder, 1 gal of water and 1lb of malt:

Crystal 10L, Plato=6.5, Extraction%=58, PPG=26

Crystal 40L, Plato=5.5, Extraction%=48, PPG=22

Crystal 120L, Plato=4.0, Extraction%=35%, PPG=16

Kaiser

Well-Known Member

I think the formula will result a valid max extraction IF you use the malt blended into powder, in order to make the milling process not a variable, agree?

yes, powdered malt will have the best extraction.

Interesting results that you got from the malts. I didn't think that C120 would have such a low extraction.

Kai

SC_Ryan

Well-Known Member

Subscribed. I'm really interested to see the difference in just the base malt, then how the base malt affects the fermentability of the crystal malts. I assume you are going to keep your milling, mashing and sparging techniques the same as your first two batches in order to make the data comparable?

SamBrewer

Well-Known Member

that's very interesting!!! I really appreciate people like you who spend time doing experiments and share with us this kind of information!

Pretty awesome thread. I am tracking the effects of different grain bills, mash temps and ferm temps with Wyeast 1968 right now. I am not being scientific about it at all, just recording results of all my batches right now to try and figure out some estimated equation to predict the fermentability of my beers overall.

I'm subscribing and can't wait for your "50/50" results. Btw - Can you repeat this experiment with ALL malts after you're done? I'm sure the brewing community would love a resource like this (even though it apparently exists online already - yeah... good luck finding it).

I'm sure the brewing community would love a resource like this (even though it apparently exists online already - yeah... good luck finding it).

P.S. It amazes me that people with 1,000's of posts can make such generalized statements about such scientific matters, make simple incorrect assumptions and discourage personal experimentation Thank goodness for people like you and Kai who get it. and provide a great service to the rest of us.

Thank goodness for people like you and Kai who get it. and provide a great service to the rest of us.

I'm subscribing and can't wait for your "50/50" results. Btw - Can you repeat this experiment with ALL malts after you're done?

P.S. It amazes me that people with 1,000's of posts can make such generalized statements about such scientific matters, make simple incorrect assumptions and discourage personal experimentation

motobrewer

I'm no atheist scientist, but...

P.S. It amazes me that people with 1,000's of posts can make such generalized statements about such scientific matters, make simple incorrect assumptions and discourage personal experimentationThank goodness for people like you and Kai who get it. and provide a great service to the rest of us.

uh, what?

Hermit

fuddle

I use Brewtarget. If you change the amount of crystal malt the ABV number changes. The author of the program must be modeling it off of something.

Interesting results so far, but you have only tried gravities around 1.020 which I suspect is artificially limiting your attenuation.

A factor in attenuation of yeast is the amount of fermentable sugar which remains in the wort when the concentration is too low for the crabtree effect to continue causing the yeast to switch off their metabolism, which for most saccharomyces strains is around 2*P. Since you are starting with a 5*P wort, there isn't much alcohol to decrease your FG, so this threshold will be just below 2*P apparent attenuation which is about 1.008 -- suspiciously close to your results.

Your methods are sound, so I think you will produce very useful data if you try wort gravities of 1.040, 1.050, 1.060 which are more typical of normal strength beers.

As an aside, many brettanomyces strains are capable of consuming sugars at below 2*P, even as low as 0.5*P, which is why it's so easy to get a significant brett infection (eg. gusher) even after a beer is fermented...

A factor in attenuation of yeast is the amount of fermentable sugar which remains in the wort when the concentration is too low for the crabtree effect to continue causing the yeast to switch off their metabolism, which for most saccharomyces strains is around 2*P. Since you are starting with a 5*P wort, there isn't much alcohol to decrease your FG, so this threshold will be just below 2*P apparent attenuation which is about 1.008 -- suspiciously close to your results.

Your methods are sound, so I think you will produce very useful data if you try wort gravities of 1.040, 1.050, 1.060 which are more typical of normal strength beers.

As an aside, many brettanomyces strains are capable of consuming sugars at below 2*P, even as low as 0.5*P, which is why it's so easy to get a significant brett infection (eg. gusher) even after a beer is fermented...

uh, what?

Sorry. Not directed at you Motor (and definitely not OP). I wondered if I should even say anything at all - didn't want to start a pissing match with someone...

There were just some comments earlier in the thread with some info that I would not expect from someone with 1,000's of posts.

Anyway, I don't want to detract from the awesome work nilo has done so far and can't wait for the next series!

Demolitron

New Member

My understanding is that the Crabtree effect is a metabolic regulator that inhibits aerobic respiration in the presence of high concentrations of sugars and causes the yeast to perform fermentation under aerobic conditions. If you could post a link for further information I would like to read it.

I also have come to understand that gusher infections are caused by bacteria and yeasts that are capable of utilizing the long chain sugars that "normal" yeasts are incapable of metabolizing. I believe that "brett" is a good example of such a critter.

It sounds like the OP is performing a forced fermentation by extreme over-pitching and warm conditions. So all of the ferment-able sugars should be consumed before the yeast flocculate out/die off.

https://www.homebrewtalk.com/wiki/index.php/Understanding_Attenuation

http://en.wikipedia.org/wiki/Crabtree_effect

http://mic.sgmjournals.org/cgi/reprint/44/2/149.pdf

I also have come to understand that gusher infections are caused by bacteria and yeasts that are capable of utilizing the long chain sugars that "normal" yeasts are incapable of metabolizing. I believe that "brett" is a good example of such a critter.

It sounds like the OP is performing a forced fermentation by extreme over-pitching and warm conditions. So all of the ferment-able sugars should be consumed before the yeast flocculate out/die off.

https://www.homebrewtalk.com/wiki/index.php/Understanding_Attenuation

http://en.wikipedia.org/wiki/Crabtree_effect

http://mic.sgmjournals.org/cgi/reprint/44/2/149.pdf

Interesting results so far, but you have only tried gravities around 1.020 which I suspect is artificially limiting your attenuation.

A factor in attenuation of yeast is the amount of fermentable sugar which remains in the wort when the concentration is too low for the crabtree effect to continue causing the yeast to switch off their metabolism, which for most saccharomyces strains is around 2*P. Since you are starting with a 5*P wort, there isn't much alcohol to decrease your FG, so this threshold will be just below 2*P apparent attenuation which is about 1.008 -- suspiciously close to your results.

Your methods are sound, so I think you will produce very useful data if you try wort gravities of 1.040, 1.050, 1.060 which are more typical of normal strength beers.

As an aside, many brettanomyces strains are capable of consuming sugars at below 2*P, even as low as 0.5*P, which is why it's so easy to get a significant brett infection (eg. gusher) even after a beer is fermented...

gxm

Well-Known Member

I just wanted to say cheers to Nilo

I'd been wanting to do these experiments since I started writing my own beer spreadsheet after realizing that the brewing apps didn't handle fermentability correctly.

I'd been wanting to do these experiments since I started writing my own beer spreadsheet after realizing that the brewing apps didn't handle fermentability correctly.

Great work Nilo.

- Joined

- Jun 2, 2008

- Messages

- 64,955

- Reaction score

- 16,524

Sorry. Not directed at you Motor (and definitely not OP). I wondered if I should even say anything at all - didn't want to start a pissing match with someone...

There were just some comments earlier in the thread with some info that I would not expect from someone with 1,000's of posts.

Anyway, I don't want to detract from the awesome work nilo has done so far and can't wait for the next series!

Since you are obviously referring to me, for the record I was the one that e-mailed Kai to let him know about this thread as he doesn't keep up on HBT anymore...

And if you read my posts you would see I disclaimered everything with the fact that I don't use brewing software so I was surprised that the software doesn't appear to attempt to take this into account.

In the future, go ahead and call me out personally - I can take it; that's why I continued to have a dialogue with nilo when I was cleary wrong.

Hermit

fuddle

i use brewtarget. If you change the amount of crystal malt the abv number changes. The author of the program must be modeling it off of something.

and if you read my posts you would see i disclaimered everything with the fact that i don't use brewing software so i was surprised that the software doesn't appear to attempt to take this into account.

If we are referring to how fermentable crystal grains are, it is taken into account in software, at least brewtarget.

If we are referring to how fermentable crystal grains are, it is taken into account in software, at least brewtarget.

as far as I know, all brewing tools assume all sugars/malts 100% fermentable, including crystals, dextrins and lactoses.

That been said, you will see the change to the ABV when you plug in crystal malts, but that will not be a correct value, specially if your grain bill has lots of crystal malts.

I don't know brewtarget though.

Hermit

fuddle

"Official" answer I guess.

http://www.specialtymalts.com/maltster/faq_brewing.html

Answer

Caramel malts add very little in the way of fermentable sugars.

I would suggest increasing the amount of base malt you use in order to reach your desired higher gravity. I sent in a question to see if they have 'published' data available since unpublished wouldn't do much good.

Not that specific I guess. Could be a percentage thing.

http://www.specialtymalts.com/maltster/faq_brewing.html

Answer

Caramel malts add very little in the way of fermentable sugars.

I would suggest increasing the amount of base malt you use in order to reach your desired higher gravity. I sent in a question to see if they have 'published' data available since unpublished wouldn't do much good.

Not that specific I guess. Could be a percentage thing.

Hermit

fuddle

At least Cargill doesn't appear to publish the data:

Caramel Malts usually fall into the high 60's range as far as percent fermentable extract.

-----Original Message-----

From: ]

Sent: Monday, January 17, 2011 10:19 AM

To: Ryan, Ron -

Subject: New Question in Ask the Maltster

The following message was submitted at the "Ask the Maltster" page.

----------------------------------------------------------------------

Is there published data on the percentage of fermentable extract from

caramel malts?

Thank You

----------------------------------------------------------------------

To answer this question and/or post it to the FAQ page go to:

http://www.specialtymalts.com/admin/data_admin.html

Caramel Malts usually fall into the high 60's range as far as percent fermentable extract.

-----Original Message-----

From: ]

Sent: Monday, January 17, 2011 10:19 AM

To: Ryan, Ron -

Subject: New Question in Ask the Maltster

The following message was submitted at the "Ask the Maltster" page.

----------------------------------------------------------------------

Is there published data on the percentage of fermentable extract from

caramel malts?

Thank You

----------------------------------------------------------------------

To answer this question and/or post it to the FAQ page go to:

http://www.specialtymalts.com/admin/data_admin.html

Back into action here guys. Sorry for the long break :cross:

As planned, finished brewing the next test batch today, with only 2 row malt.

Mashed and brewed 3 separated batches with 1# 2row and 1/4# rice rulls, following the same procedures than used for the crystal malts ( milled 3 times, etc. ).

The results were as expected, a higer attenuation (mashed at 155F), no starch detected in wort. These results were consistent among the 3 test batches, so I'm happy with the results.

One thing I must comment is the PPG numbers I'm getting. Even when milling the grain 3 times, I'm not getting the full potential of the grain, either crystal or the 2row just tested.

That could be confirmed when I tested the potential using the method suggested by Kai, which gave me the following results:

Crystal 10L: 26

Crystal 40L: 22

Crystal 120L: 16 (I may test this again to confirm)

2Row : 31

So don't pay much attention to the PPG numbers at the table below.

Here's the fermentation profile and the table with the results so far.

As planned, finished brewing the next test batch today, with only 2 row malt.

Mashed and brewed 3 separated batches with 1# 2row and 1/4# rice rulls, following the same procedures than used for the crystal malts ( milled 3 times, etc. ).

The results were as expected, a higer attenuation (mashed at 155F), no starch detected in wort. These results were consistent among the 3 test batches, so I'm happy with the results.

One thing I must comment is the PPG numbers I'm getting. Even when milling the grain 3 times, I'm not getting the full potential of the grain, either crystal or the 2row just tested.

That could be confirmed when I tested the potential using the method suggested by Kai, which gave me the following results:

Crystal 10L: 26

Crystal 40L: 22

Crystal 120L: 16 (I may test this again to confirm)

2Row : 31

So don't pay much attention to the PPG numbers at the table below.

Here's the fermentation profile and the table with the results so far.

HairyDogBrewing

Well-Known Member

Excellent experiment.

Question: Since you detected starch in the crystal mashes,

do you think the FGs would go lower if you added enymes to the mash?

Question: Since you detected starch in the crystal mashes,

do you think the FGs would go lower if you added enymes to the mash?

Excellent experiment.

Question: Since you detected starch in the crystal mashes,

do you think the FGs would go lower if you added enymes to the mash?

Yes, I think you would get more sugars, some would be fermentable, so you would reach a lower FG.

Yes, I think you would get more sugars, some would be fermentable, so you would reach a lower FG.

OK, let me quote my own post here.

If you add more sugars, you will have a higher OG also. Since some of the extra sugars will be non-fermentable, you will probably end at a higher FG than if you didn't add any enzymes. You would get move alcohol though. I think

Similar threads

- Replies

- 5

- Views

- 761

- Replies

- 28

- Views

- 759

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)