BrewMoreBeers

Well-Known Member

subscribed.

Did you do the starch test on a paper towel?

Also, how did you take the gravity readings?

=>Yes

=>Daily with a refractometer.

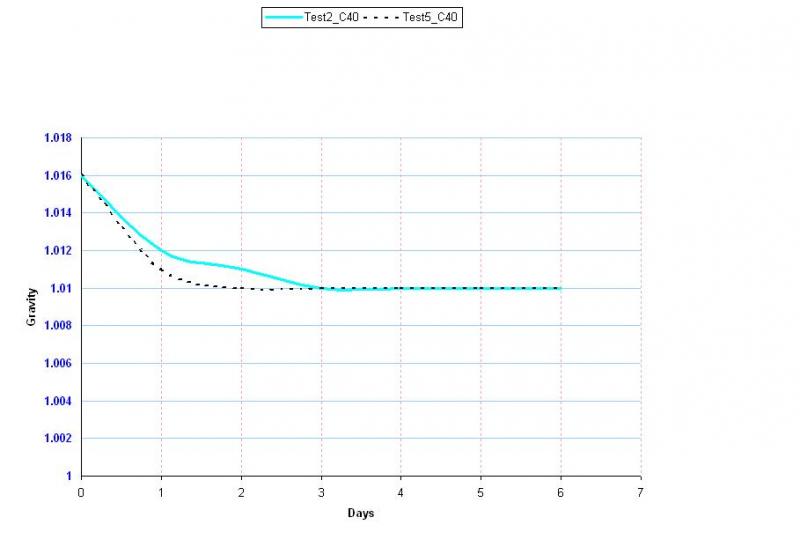

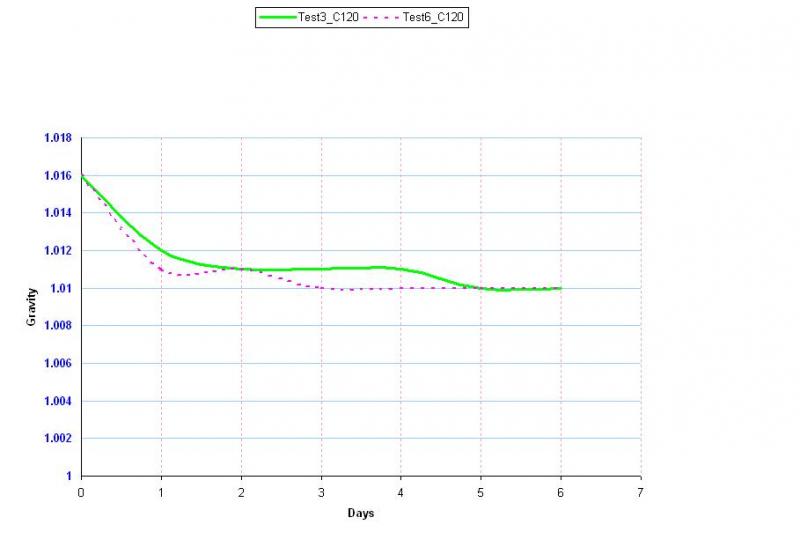

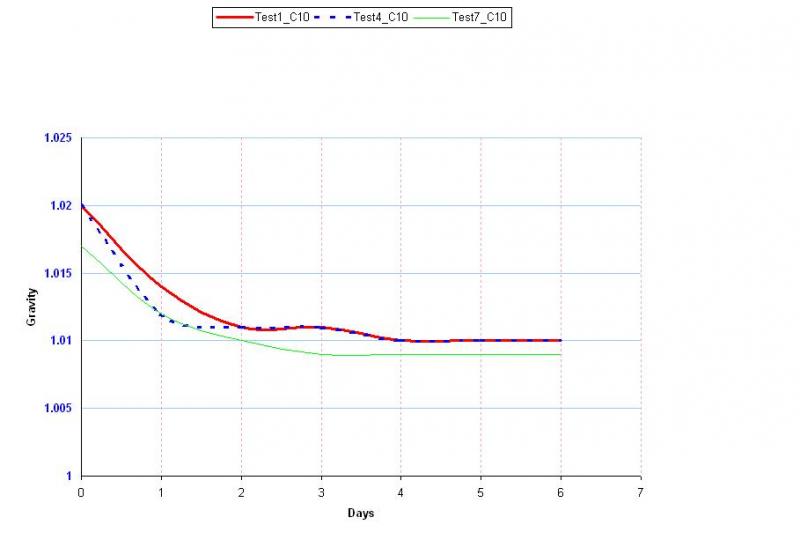

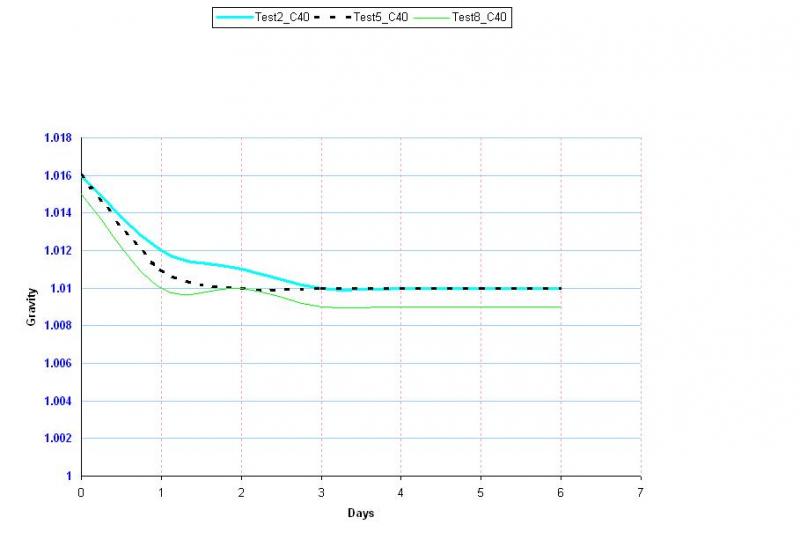

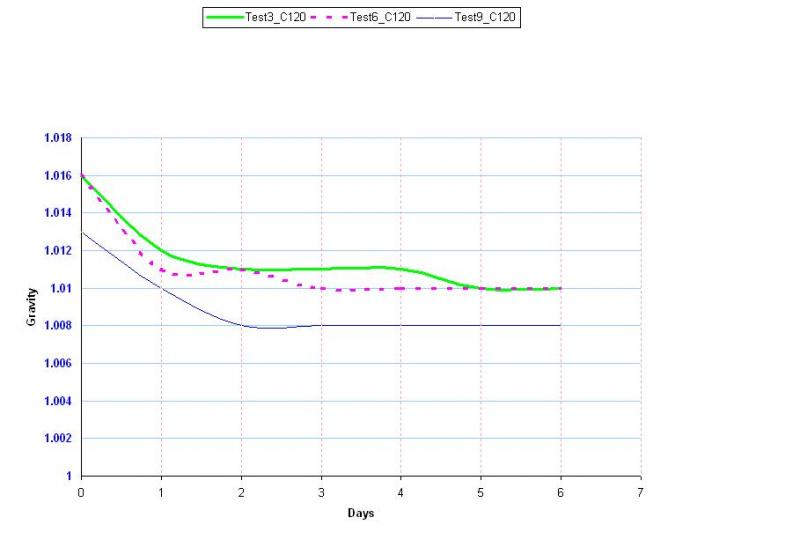

interesting. i'm still confused as to why they all stopped at 1.01. i mean, that seems pretty random....

i figured they would all be x% fermentable.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

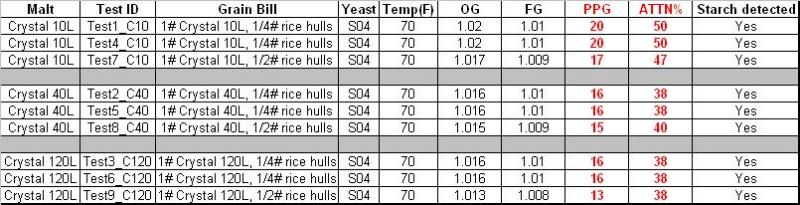

I recently learned from this forum that beta amylase can actually convert the long sugars (at some level) to shorter chains that become then fermentable, so I think that if you mash a crystal malt with another malt with diastatic power, it will affect the fermentability of the points coming from the crystal.

Interesting that the FG is winding up at 1.01 so far regardless of the malt.. I wonder why that is? It seems unlikely that the different malts would jsut happen to have the exact right amount of fermentables to make it come out that way with different OGs.... I wonder if 2# of 120 was used in 1 gal if it would still make it down to 1.01?

Have you tasted the final product? Just curious. It would obviously seem very sweet with the lack of hops.

It tastes nasty. I think it could be because the extraction of tanins during sparge as I washed the grain many times to get all possible sugars or because the yeast got stressed in processing the not so much fermentable sugars.

Nilo, thanks for the update and thanks for sticking with this experiment. Its the oddities in results that keep you thinking about refined experiments, isnt it?

As for sparging, you dont have to try to get all the sugar out of the grain. Doing a no-sparge, for example is sufficient. You can assess the grain potential based on the mash thickness and the gravity of the wort. Thats what maltsters do when they determine the extract potential.

The formula is

Extract potential = 100 * (Plato R) / (100 Plato)

Where Plato is the extract content of the wort in the mash and R is the mash thickness in l/kg. extract potential is then given in % of the malts weight. This cuts out the lauter efficiency.

Kai

Yes, this extract potential is still affected by milling and mashing. If you put this potential in relation to the fine grid extract potential (after compensating for moisture content) you get the conversion efficiency.Kai, the extract potential from this formula will still be affected by the milling process, right?

What I'm saying is that if you mill the grain coarse, mash and use this formula, the resulted extract potential will be less than if you mill it fine and redo the test.

I see your point about getting the lauter efficiency to 100%. However, this is not needed if you determine conversion efficiency or extract achieved after mashing by using aforementioned formula. When I did my mashing experiments I wasnt aware of this either and my process was to keep the lauter efficiency constant by using the same batch sparge method each time. If I would have known about conversion efficiency at the time I would have been able to get actual conversion efficiency numbers.What I was trying to do is to make the sugars as much soluble as possible by milling several times and to make my lautering efficiency close to 100% by washing it very well.

I'm not very convinced yet that I'm doing my best to extract the sugars. I may do a batch next using the grain turned into fine powder.

The amount of sugars extracted was actually less than before,

Kai, I didn't and I'm confused. Do you mean to stir the mash before lautering and measure the gravity of the wort? if I just collect a sample from the mash tun from the spigot without stirring, that will mostly be a concentrated wort that sit on the bottom of the mash tun.

Im trying to understand the formula you listed:

Extract potential = 100 * (Plato R) / (100 Plato)

Just for understanding the formula, lets assume I stirred the mash and took a reading of 17 plato = 1.070. I used 0.75gals of water = 2.84l and 1lb of grains=0.453Kg.

Using the formula, the Extract Potential would be 13%. How do I get PPG from this value?

I think the formula will result a valid max extraction IF you use the malt blended into powder, in order to make the milling process not a variable, agree?

P.S. It amazes me that people with 1,000's of posts can make such generalized statements about such scientific matters, make simple incorrect assumptions and discourage personal experimentationThank goodness for people like you and Kai who get it. and provide a great service to the rest of us.

uh, what?

Interesting results so far, but you have only tried gravities around 1.020 which I suspect is artificially limiting your attenuation.

A factor in attenuation of yeast is the amount of fermentable sugar which remains in the wort when the concentration is too low for the crabtree effect to continue causing the yeast to switch off their metabolism, which for most saccharomyces strains is around 2*P. Since you are starting with a 5*P wort, there isn't much alcohol to decrease your FG, so this threshold will be just below 2*P apparent attenuation which is about 1.008 -- suspiciously close to your results.

Your methods are sound, so I think you will produce very useful data if you try wort gravities of 1.040, 1.050, 1.060 which are more typical of normal strength beers.

As an aside, many brettanomyces strains are capable of consuming sugars at below 2*P, even as low as 0.5*P, which is why it's so easy to get a significant brett infection (eg. gusher) even after a beer is fermented...