This is the typical wiring I see on SD forums. Where does the switch, ammeter, and contactor fill in? What exactly is the contactor? I've seen a ton of wiring diagrams and I don't know what's needed or the order of them. My learning in electricity stopped at high school physics.

Does anything special have to happen for adding a 120V outlet as well for my pump?

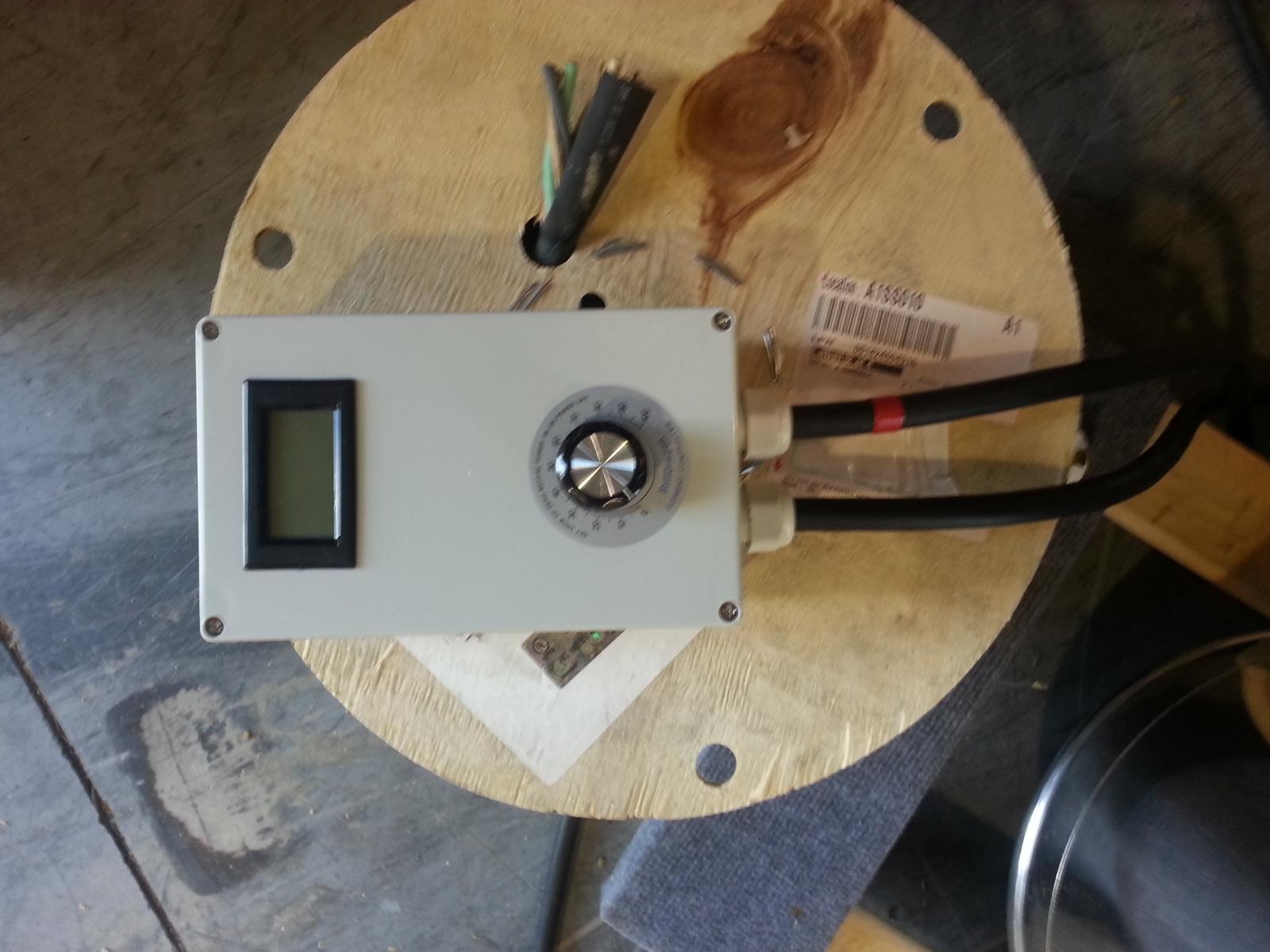

And I priced the parts out and it's still cheaper I believe to get the stilldragon kit and go from there. I would get the larger box as well. HxWxL: 3.75"x7.25"x10.38"

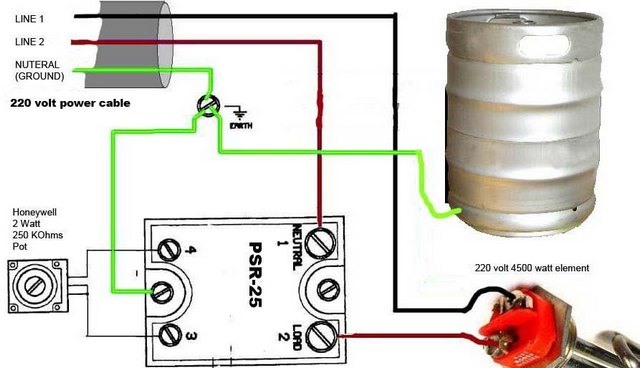

Here's a schematic of how to switch an SSVR (what the StillDragon controller is) between two different heating elements:

If you don't understand the drawing, or how to actually implement the wiring, you should contact an electrician (or someone else knowledgeable.) Electricity can kill you if you get it wrong!

A contactor is an electromagnetic relay designed for switching high currents. They are activated using much smaller currents than they are controlling. The contactors for this application would be Auber Instruments CN-PBC302-120V (

http://www.auberins.com/index.php?main_page=product_info&cPath=2_31&products_id=129), or similar. To control the contactors you need a three position, ON-OFF-ON switch like the Auber SW3 (

http://www.auberins.com/index.php?main_page=product_info&cPath=7_32&products_id=235). Using this type of switch insures that you cannot connect the SSVR output to more than one heater at a time.

A 4 A slow-blow fuse will handle the contactor coil currents and a typical Chugger pump. You want a slow-blow fuse as the pump motor starting current is usually higher than the running current.

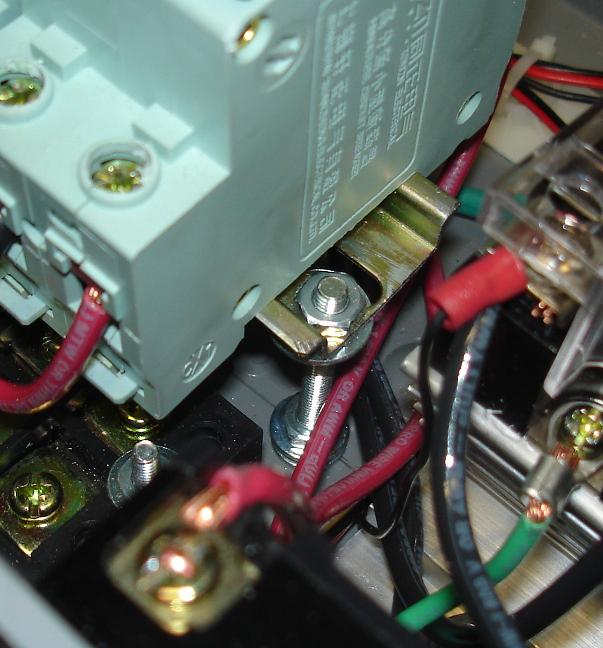

The Black, Red, and Purple hot wires, and the ground wires for the heaters all need to be 10 gauge stranded in order handle 30 A safely. The Hot Pink hot, and Gray neutral wires can be 14 or 16 gauge stranded as they don't have to handle more than 4 amps.

In order to have 120 volts available in your control box, the input power feed needs to be 4 wires (2 hot, 1 neutral, 1 ground). Without the neutral, you cannot have 120 V available.

This power feed should be protected by a 30 amp GFCI breaker or spa panel (which has a GFCI breaker.)

I forgot to add the ammeter to the schematic. Maybe I can get that done tomorrow.

Brew on

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)