kal

Well-Known Member

Thanks for the info! Your hopping amount of 14.4 oz per 12 gallons is similar to mine (16 oz per 12 gallons). Just different temps and time.I recently did a similar experiment, except I didn't add any mash hops. I did a split batch, half of which (2.5 gallons) received 3 oz of hops held at 200F for 30 minutes, and half of which received 3 oz of hops held at 175 for 30 minutes. The 200 beer was plenty bitter, maybe 40 IBUs. The 175 beer was markedly less bitter, but certainly not cloyingly sweet—maybe 25 IBUs. The 175 beer had more hop aroma.

To be clear, I didn't add any mash hops either.

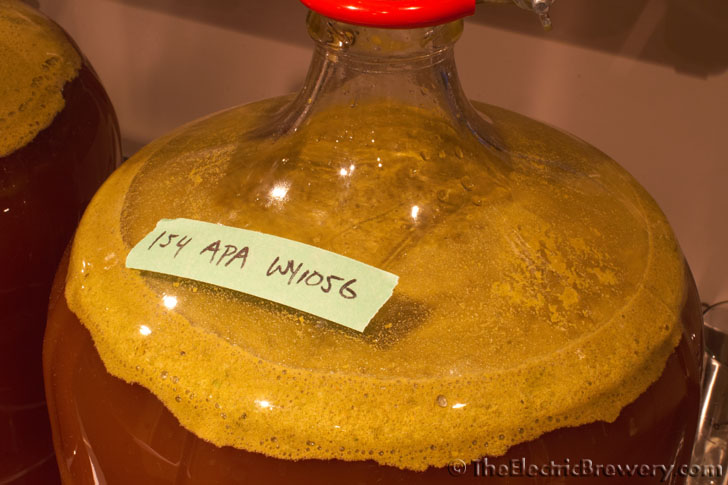

Both fermenters are still actively fermenting... I'll likely give them 2 weeks to finish up fermenting and allow the yeast a chance to clean up after itself and then rack and dry hop.

Kal

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)